High Elastomeric EPDM Rubber underground Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Rubber Waterproof Membrane:

1. EPDM Rubber Waterproof Membrane uses the technology of internationally advanced level-cold feed extruder continuous vulcanization, chooses imported epdm and accessories with high quality. The production is of well quality according to the national standards.This product has the high elasticity and high elongation and high tear strength and excellent low temperature performance and water resistance, ozone resistance, aging resistance performance .

Main Features of EPDM Rubber Waterproof Membrane:

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

Specifications of EPDM Rubber Waterproof Membrane:

Type | EPDM Rubber Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

Applications of EPDM Rubber Waterproof Membrane:

1 Roofs, Basement, Toilet

2 Industrial and civil building waterproofing

3 Geosynthetic liner for swimming pool, channels, irrigation system

4 Especially suit for projects with high requirements in durability, anti-corrosion and deformation

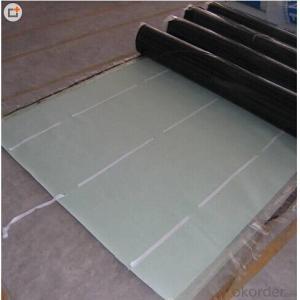

IMages of EPDM Rubber Waterproof Membrane:

FAQ:

Q1.:What are we supplying?

A1:We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

Q2: How Many years experience do we have?

A2:We have exported to more than 20 countries in the last 15 years.

Q3.:Do you provide samples for us?

A3:Yes,We will provide samples for free.Waiting for your your good news.

- Q: Does a waterproofing membrane require any specific surface preparation?

- Specific surface preparation is necessary prior to the installation of a waterproofing membrane. The quality and condition of the surface play a significant role in determining the success and effectiveness of the membrane. To begin with, the surface must be thoroughly cleaned and devoid of any dirt, debris, oil, grease, or loose particles. This can be accomplished by utilizing a pressure washer, scrub brush, or appropriate cleaning agents. Additionally, any existing coatings or sealants must be eliminated to ensure proper adhesion of the membrane. Furthermore, the surface should be even and smooth. Any uneven areas, cracks, or holes need to be repaired and leveled prior to applying the membrane. This can be achieved by filling the cracks or holes with a suitable filler or patching compound and smoothing it out to establish a uniform surface. Moreover, it is imperative that the surface is completely dry. Moisture can compromise the adhesion and effectiveness of the waterproofing membrane. Therefore, it is essential to ensure the surface is fully dry before commencing the installation. This may involve allowing the surface to air dry or employing appropriate drying methods such as fans or dehumidifiers. In addition to these general surface preparations, specific types of waterproofing membranes may entail additional requirements. For instance, certain membranes may necessitate the application of a primer on the surface before installation. It is crucial to adhere to the manufacturer's instructions and recommendations for the specific membrane being used. Overall, proper surface preparation is vital for the accomplishment of a waterproofing membrane installation. It guarantees optimal adhesion, durability, and performance of the membrane, ultimately preventing water penetration and safeguarding the underlying structure.

- Q: Can a waterproofing membrane be applied to roofing systems?

- Yes, a waterproofing membrane can be applied to roofing systems. Waterproofing membranes are commonly used in roofing to provide an additional layer of protection against water and moisture infiltration. These membranes are typically made of synthetic materials such as PVC or EPDM and are designed to be durable, flexible, and resistant to environmental factors such as UV radiation and temperature fluctuations. When properly installed, a waterproofing membrane can help to prevent leaks, extend the lifespan of the roof, and protect the underlying structure from water damage. It is important to consult with a professional roofing contractor to determine the most suitable type of waterproofing membrane for a specific roofing system and to ensure proper installation and maintenance.

- Q: Can a waterproofing membrane be customized or tailored to specific project requirements?

- Yes, a waterproofing membrane can be customized or tailored to specific project requirements. Waterproofing membranes come in various types and materials, such as bituminous, synthetic, or liquid-applied membranes. These membranes can be modified or adjusted to meet the specific needs of a project. Customization can involve factors like the thickness or weight of the membrane, the type of reinforcement used, the method of application, and the specific performance requirements of the project. For example, a high-traffic area may require a thicker or more durable membrane to withstand heavy loads, while a project in a harsh climate may necessitate a membrane with enhanced resistance to UV radiation or extreme temperatures. Furthermore, the membrane can be tailored to different substrates or surfaces, such as concrete, metal, or wood, by using compatible adhesives or primers. This ensures proper bonding and longevity of the waterproofing system. Additionally, some waterproofing membranes offer customizable options for color or appearance, allowing them to blend seamlessly with the overall aesthetic of the project. Overall, the customization of a waterproofing membrane allows it to be specifically designed and engineered to meet the unique requirements of each project, ensuring optimal performance and long-lasting protection against water damage.

- Q: Can a waterproofing membrane be used in steam rooms?

- Indeed, the utilization of a waterproofing membrane within steam rooms is possible. This specialized membrane is crafted to obstruct water infiltration and is commonly employed in areas where moisture is prevalent, such as bathrooms, showers, and steam rooms. The primary function of this membrane is to create a barrier that hinders water vapor from penetrating the underlying structure and inducing harm. In the case of steam rooms, where elevated levels of humidity and moisture are abundant, the implementation of a waterproofing membrane is imperative in safeguarding the walls, floors, and other surfaces from water damage and the growth of mold. It is of utmost importance to select a waterproofing membrane that is explicitly designed for environments with high moisture content, such as steam rooms, in order to ensure sufficient protection and durability. Furthermore, for the membrane to effectively fulfill its purpose within a steam room setting, proper installation and adherence to the guidelines provided by the manufacturer are essential.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Yes, a waterproofing membrane typically requires specific preparation of the substrate before installation. The substrate, which is the surface on which the membrane will be applied, needs to be clean, dry, and free from any contaminants or debris that could hinder the adhesion of the membrane. This usually involves removing any loose materials, such as old paint or sealants, and smoothing out any uneven surfaces. Additionally, it may be necessary to repair any cracks or damage in the substrate to ensure a proper and effective installation of the waterproofing membrane. Following the recommended preparation procedures will help to maximize the performance and durability of the membrane, ensuring its effectiveness in preventing water penetration and protecting the underlying structure.

- Q: Does a waterproofing membrane prevent water infiltration through concrete or other building materials?

- Yes, a waterproofing membrane is designed to prevent water infiltration through concrete or other building materials. It acts as a protective barrier that is applied to the surface of the material, forming a water-resistant layer. This membrane can be made from various materials such as bitumen, rubberized asphalt, or liquid polymers. When properly installed, it can effectively prevent water from seeping through the concrete or other building materials, thus protecting the structure from potential water damage or moisture-related issues.

- Q: Can a waterproofing membrane be used for basements?

- Basements can benefit from the use of a waterproofing membrane. In fact, it is an extremely effective solution for safeguarding against water infiltration and moisture damage. A waterproofing membrane acts as a protective barrier, applied to the exterior walls and/or floors of a basement. Its purpose is to resist hydrostatic pressure, which is the force exerted by water on the walls and floors. By implementing a waterproofing membrane, the risk of water damage, mold growth, and structural issues in your basement can be significantly reduced. It's important to emphasize that proper installation and maintenance of the membrane are essential for optimal effectiveness. Therefore, it is advisable to seek the assistance of a professional waterproofing contractor for the best outcome.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They can effectively prevent water intrusion and protect homes from moisture damage, making them an ideal solution for basements, foundations, roofs, and other areas prone to water leakage.

- Q: Basement SBS Waterproof Coil Division I and II type What is the difference? How is the site identified?

- SBS type I and type II differences are mainly low temperature flexibility and tensile extension. Type I low temperature flexibility is -20 degrees, pulling force of 500N / 5cm, elongation of 30%. Type II low temperature is -25 degrees, tension of 800N / 5cm, elongation of 40%. The appearance of the general can not distinguish, you can do experiments.

- Q: Can a waterproofing membrane be installed on bathroom or shower walls?

- Installing a waterproofing membrane on bathroom or shower walls is a must. It is highly recommended to prevent water damage and leakage. The membrane acts as a barrier, stopping water from seeping through and causing mold, mildew, or structural damage. It is usually applied before tiling to protect the entire surface. This is crucial in moisture-prone areas like bathrooms and showers. By using a waterproofing membrane, you guarantee the long-lasting durability of your walls and maintain a safe and healthy environment in your bathroom or shower.

Send your message to us

High Elastomeric EPDM Rubber underground Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords