EPDM Rubber Waterproof Membrane for Ponds with 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of EPDM Waterproof Membrane:

1. the excellent anti-aging, in the long term light, humidity, cold use of the natural environment, small changes in physical properties, used in the temperature:From -50 degree Celsius to +80degree Celsious

2. EPDM waterproof membrane production vulcanized/sulfuretted EPDM rubber roofing waterproof membrane

Main Features of EPDM Waterproof Membrane:

1). Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Specifications of EPDM Waterproof Membrane:

ITEM | STANDARO REQUEST | |

Tensile strength at breaking,normal temperature,Mpa | ≥7.5 | |

Elongation at breaking, % | ≥450 | |

Tearing strenght,KN/m | ≥25 | |

Bending at low temperature | ≤-40°C | |

Water impermeability,0.1Mpa×30min | Impermeability | |

Hot air aging 80°C×168h | Unchanging of tensile strength at breaking,% | ≥80 |

Unchanging of elongation at breaking,% | ≥70 | |

Appearance of 100% elongation | No crack | |

Property of anti alkali 10% Ca(OH)2×168h normal temperature | ≥80 | |

≥80 | ||

Applications of EPDM Waterproof Membrane:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

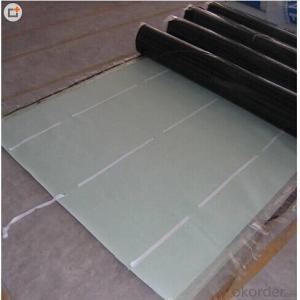

IMages of EPDM Rubber Waterproof Membrane:

FAQ:

Q1.:What are we supplying?

A1:We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

Q2: How Many years experience do we have?

A2:We have exported to more than 20 countries in the past 15 years.

Q3.:Do you provide samples for us?

A3:Yes,We will provide samples for free.Waiting for your your good news.

- Q: Are waterproofing membranes resistant to frost damage?

- Waterproofing membranes, in general, exhibit resistance towards frost damage. These membranes are specifically crafted to endure diverse weather conditions, which include freezing temperatures. They typically comprise modified bitumen, PVC, EPDM, or TPO, materials renowned for their exceptional frost and environmental resistance. These materials are engineered to maintain their flexibility and elasticity, even in low temperatures, ensuring the preservation of the waterproofing membrane's effectiveness in preventing water infiltration. Furthermore, meticulous installation methods and regular maintenance can augment the waterproofing membranes' resistance to frost damage.

- Q: Can waterproofing membranes be used on concrete tanks?

- Yes, waterproofing membranes can be used on concrete tanks. Waterproofing membranes are commonly used to prevent water penetration and protect concrete structures from water damage. Concrete tanks, like other concrete structures, are susceptible to water infiltration over time, which can lead to deterioration and structural issues. Applying a waterproofing membrane on the concrete surface can effectively prevent water penetration, making the tank more durable and extending its lifespan. There are various types of waterproofing membranes available, such as liquid-applied membranes, sheet membranes, and cementitious coatings, each with its own advantages and suitability for different applications. It is important to choose the right type of waterproofing membrane based on factors like the tank's usage, exposure to water pressure, and environmental conditions. Additionally, proper surface preparation and application techniques are essential for ensuring the effectiveness and longevity of the waterproofing membrane on the concrete tank.

- Q: How does a waterproofing membrane handle water migration through the substrate?

- A waterproofing membrane is designed to prevent water migration through the substrate. It acts as a barrier, preventing water from infiltrating the substrate and causing damage to the structure. The membrane is typically applied to the exterior side of the substrate, creating a watertight seal. To handle water migration, the membrane is typically made from a flexible and durable material such as modified bitumen, PVC, or EPDM. These materials have excellent waterproofing properties and can withstand exposure to water, UV rays, and other environmental factors. The membrane is installed in a way that ensures proper adhesion to the substrate, creating a seamless and continuous barrier. It is often applied in multiple layers to further enhance its effectiveness. The seams and joints are also properly sealed to prevent any potential water leaks. In addition to its primary waterproofing function, the membrane also helps to manage water that may accumulate on the surface. It is designed with a slope or drainage system, directing water away from critical areas and towards appropriate outlets or drains. Overall, a waterproofing membrane is specifically engineered to handle water migration through the substrate by creating a reliable and long-lasting barrier against moisture. It is an essential component in protecting structures from water damage and ensuring their durability and longevity.

- Q: Can a waterproofing membrane be used on terracotta surfaces?

- Yes, a waterproofing membrane can be used on terracotta surfaces.

- Q: Is a waterproofing membrane suitable for use in areas with high groundwater levels?

- A waterproofing membrane works well in areas where the groundwater levels are high. Its purpose is to stop water from getting in, making it an effective barrier against groundwater. These membranes are usually made from materials like bitumen, PVC, or EPDM, which are extremely resistant to water and can handle a lot of pressure from below. They are built to create a tight seal, keeping water out of buildings or underground areas. Because of this, a waterproofing membrane is the perfect choice for places with high groundwater levels. It can successfully guard against water infiltration and the potential harm it could cause to structures or infrastructure.

- Q: Can waterproofing membranes be used on concrete stairs?

- Yes, waterproofing membranes can be used on concrete stairs. These membranes are designed to create a protective barrier against water penetration, which is particularly important for areas exposed to moisture such as outdoor or basement stairs. Applying a waterproofing membrane on concrete stairs can help prevent water damage, increase their durability, and extend their lifespan.

- Q: Can a waterproofing membrane be used for wastewater treatment plants?

- Indeed, wastewater treatment plants can make use of a waterproofing membrane. Waterproofing membranes are frequently employed in various construction undertakings, including wastewater treatment plants, to establish a barrier against the infiltration of water. These membranes are specifically designed to prevent water from permeating the structure, which is of utmost importance for wastewater treatment plants due to their handling of considerable water volumes. Wastewater treatment plants constantly face exposure to water and high levels of humidity, which may result in moisture-related harm and structural degradation. By incorporating a waterproofing membrane, the facility can effectively avert water penetration, thereby ensuring the soundness and longevity of the structure. Furthermore, wastewater treatment plants commonly contain diverse corrosive chemicals and substances that can cause damage to the structure over time. Waterproofing membranes can serve as a protective layer, effectively shielding the building materials against these chemicals and deterring structural problems. Various types of waterproofing membranes are available, such as sheet membranes, liquid membranes, and cementitious membranes. The selection of a suitable membrane depends on the specific requirements, financial considerations, and prevailing conditions at the wastewater treatment plant. It is imperative to choose a membrane that is compatible with the chemicals present in the wastewater and capable of withstanding the harsh conditions prevalent at the facility. In conclusion, a waterproofing membrane proves to be an appropriate solution for wastewater treatment plants as it effectively safeguards the structure against water infiltration and chemical harm. By implementing an appropriate waterproofing system, the facility can ensure the long-term durability and operational effectiveness of the plant.

- Q: Can a waterproofing membrane be used on precast concrete surfaces?

- Yes, a waterproofing membrane can be used on precast concrete surfaces. It helps to prevent water penetration and protect the concrete from moisture damage.

- Q: Can waterproofing membranes be used on underground structures?

- Indeed, underground structures can make use of waterproofing membranes. These membranes have been designed with the aim of creating a barrier against water infiltration and are widely utilized in various applications, including basements, tunnels, and underground parking lots. The main objective of employing waterproofing membranes in underground structures is to avert water penetration, as this can lead to structural damage and compromise stability. Generally, these membranes are crafted from materials like modified bitumen, PVC, EPDM, or HDPE, all of which possess outstanding water resistance properties. By applying waterproofing membranes correctly, a continuous and robust barrier is established, preventing water from seeping through the walls, floors, or foundations of underground structures. These membranes can be installed externally or, on occasion, as an integral part of the concrete walls or floors during construction. In addition to their water resistance capabilities, waterproofing membranes also offer protection against other elements such as chemicals, gases, and radon. They prove highly effective in preventing issues related to moisture, like the growth of mold, the deterioration of building materials, and structural damage, thus ensuring the durability and integrity of underground structures. It is crucial to bear in mind that the proper installation and maintenance of waterproofing membranes are of utmost importance for their effectiveness. It is advisable to engage the services of a qualified professional who can assess the specific requirements of the underground structure and recommend the appropriate type of waterproofing membrane and installation method. All in all, waterproofing membranes serve as a dependable and efficient solution for preventing water infiltration in underground structures, providing long-lasting protection and preserving the structural integrity of the building.

- Q: Can a waterproofing membrane be used in areas with high levels of moisture and humidity?

- Yes, a waterproofing membrane can be used in areas with high levels of moisture and humidity. Waterproofing membranes are specifically designed to prevent water penetration and can effectively protect surfaces from water damage even in damp and humid environments.

Send your message to us

EPDM Rubber Waterproof Membrane for Ponds with 1.0mm/1.2mm/1.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords