EPDM Rubber Coiled Waterproof Membrane for Public

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Coiled Waterproof Membrane for Public

Description Of EPDM Rubber Coiled Waterproof Membrane for Public:

•EPDM waterproof sheet has excellent anti-ozone-aging performance, able to resist ultraviolet light and corrosion of many chemical corrosive materials in the atmosphere

•It has high tensile strength, high ductility and strong retractility, it has excellent crack resistance, able to effect waterproof function even with tiny vibration of buildings.

• Excellent resistance to ozone, oxidation and sunlight.

• Resistance to chemicals; resistant to most inorganic products.

Main Features of EPDM Rubber Coiled Waterproof Membrane for Public:

1>Excellent antiaging performance, service life up to 50 years

2>Working well with in 40C to 100C,it canbe constructed with a single layer in ambient temperature.

3>Waterproofing on various kinds of underground project,industrial of civil buildings and structures.

4>high extension rate, high tensile strength, small size changes at heat treatment

5>Good plant roots penetrability resistance and can be made waterproofing layer of planting roof

6>Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

7>Good low temperature flexibility, and good performance of adapting to ambient temperature changes.

8>Convenient application ,solid joint, no environment pollution

9>chemical corrosion Resistance, can be used for special occasions

10>Convenient maitenance, low cost.

Specifications of EPDM Rubber Coiled Waterproof Membrane for Public:

| Material | EPDM Rubber |

| Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

| Thick | 1.2mm, 1.5mm, 2.0mm |

| Type | Vulcanized & Weldable |

| Pattern | Non-reinforced (homogeneous) |

| Certificate | ISO9001/14001 |

Applications of EPDM Rubber Coiled Waterproof Membrane for Public:

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

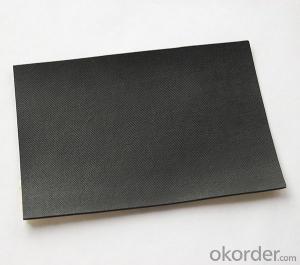

IMages of EPDM Rubber Coiled Waterproof Membrane for Public:

FAQ of EPDM Rubber Coiled Waterproof Membrane for Public:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in swimming pools or other water features?

- Certainly, swimming pools or other water features can indeed utilize a waterproofing membrane. In fact, it is highly advisable to employ such a membrane in these areas to avert water leakage and potential harm. By serving as a barrier between the water and the surrounding structures, a waterproofing membrane ensures that the water remains contained within the pool or water feature. Not only does it prevent water seepage, which can inflict structural damage and necessitate expensive repairs, but it also safeguards the pool or water feature from the harsh chemicals employed for water treatment, thereby guaranteeing its durability and long lifespan. Consequently, the utilization of a waterproofing membrane is an essential measure in the construction or renovation of swimming pools or other water features, guaranteeing their functionality and longevity.

- Q: Can a waterproofing membrane be used on rubber surfaces?

- Rubber surfaces, like roofs, decks, or rubber flooring, can benefit from the use of a waterproofing membrane. These membranes are designed to create a barrier that stops water from penetrating and harming the underlying surface. By applying a liquid or sheet membrane, it adheres to the rubber surface and forms a protective layer that prevents water from seeping through. This protective layer not only extends the lifespan of the rubber surface but also prevents problems like leaks or decay caused by moisture. However, it is crucial to ensure that the waterproofing membrane is compatible with the specific type of rubber surface being treated. Some membranes may not adhere properly or may cause damage to certain types of rubber. To guarantee proper application and compatibility, it is always recommended to consult with a professional or the manufacturer of the waterproofing membrane.

- Q: Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. These membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. They are made from materials like rubber, polyethylene, or PVC, which are inherently resistant to the corrosive effects of saltwater. This resistance allows waterproofing membranes to effectively protect structures and surfaces from water damage, even in saltwater environments. However, it is essential to choose a waterproofing membrane specifically designed for saltwater applications to ensure optimal performance and longevity.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Yes, there are some drawbacks and limitations to using a waterproofing membrane. One limitation is that it can be expensive to install, especially if it requires professional assistance. Additionally, if the membrane is not properly installed or maintained, it can become damaged or ineffective over time. Another drawback is that waterproofing membranes can limit the breathability of a structure, which can lead to moisture buildup and potential issues with mold or mildew. Finally, while a waterproofing membrane can protect against water intrusion, it may not fully address other potential sources of moisture, such as condensation or groundwater seepage.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Yes, a waterproofing membrane can be used in conjunction with fire protection systems. While the main purpose of a waterproofing membrane is to prevent water penetration, it can also provide an added layer of protection against fire hazards. Many waterproofing membranes are designed to be fire resistant or have fire-retardant properties. This means that they can help to delay the spread of fire and minimize its impact on the structure. Additionally, some waterproofing membranes are specifically designed for use in fire protection systems, such as fire-rated roof membranes or fire-resistant sealants. These specialized membranes can effectively seal off potential fire pathways and provide a barrier to protect the underlying structure. Overall, using a waterproofing membrane in conjunction with fire protection systems can enhance the overall safety and security of a building.

- Q: Can a waterproofing membrane be used on precast metal surfaces?

- Precast metal surfaces can benefit from the application of a waterproofing membrane. These membranes are specifically designed to create a protective layer that stops water from penetrating the surface. They can be used on various types of surfaces, including precast metal. Waterproofing membranes are typically made from materials like bitumen, liquid coatings, or synthetic rubber. These materials form a barrier that prevents water and moisture from causing damage. When a waterproofing membrane is applied to precast metal surfaces, it helps to prevent corrosion, protects against water damage, and improves the overall durability and lifespan of the metal structure. However, it is crucial to select a waterproofing membrane that is compatible with the specific type of precast metal surface. Additionally, proper surface preparation and application techniques must be followed to ensure optimal performance.

- Q: Are waterproofing membranes suitable for stadium structures?

- Yes, waterproofing membranes are suitable for stadium structures. Stadiums are exposed to various weather conditions such as rain, snow, and humidity, which can potentially damage the structure if proper waterproofing measures are not taken. Waterproofing membranes provide a protective layer that prevents water infiltration, thus safeguarding the stadium from moisture-related issues like leaks, mold, and corrosion. Stadium structures often have large roof areas and expansive seating areas where water can accumulate, making waterproofing crucial. Membranes can be applied on various surfaces, including concrete, metal, and wood, ensuring a versatile and effective waterproofing solution for stadiums. Moreover, waterproofing membranes offer durability and longevity, which is essential for stadiums that are subjected to heavy usage and constant exposure to the elements. They are designed to withstand thermal expansion and contraction, as well as UV radiation, ensuring long-term protection for the structure. Additionally, waterproofing membranes can be customized to meet specific design requirements, allowing architects and engineers to integrate them seamlessly into the stadium's overall aesthetic. These membranes come in various colors, textures, and finishes, enabling them to blend with the surrounding materials and enhance the visual appeal of the stadium. Overall, waterproofing membranes provide a reliable and effective solution for protecting stadium structures from water damage. They offer durability, versatility, and customization options, making them suitable for any stadium construction or renovation project.

- Q: Can a waterproofing membrane be used for a water tank liner?

- Indeed, a water tank liner can utilize a waterproofing membrane. The main purpose of waterproofing membranes is to obstruct water infiltration and can be employed on various surfaces, such as concrete, metal, and other commonly used materials in water tank construction. These membranes establish a barrier that thwarts leakage, cracks, and other types of water harm, thus guaranteeing the water tank's strength and durability. Moreover, waterproofing membranes are usually flexible, enabling them to adapt to the tank's shape and accommodate any potential movement or settlement. However, it is crucial to select a waterproofing membrane specifically engineered for water tank applications to ensure optimal performance and long-lastingness.

- Q: Can waterproofing membranes be used on concrete fountains?

- Yes, waterproofing membranes can be used on concrete fountains. Concrete fountains are often exposed to water and can be prone to leaks and moisture damage. Applying a waterproofing membrane to the concrete surface helps to create a barrier that prevents water penetration and protects the fountain structure. Waterproofing membranes are designed to be flexible, durable, and resistant to water, making them an ideal solution for concrete fountains. They can be applied to the interior and exterior surfaces of the fountain, ensuring complete protection against water damage. By using waterproofing membranes, the lifespan of the concrete fountain can be extended, and maintenance costs can be reduced.

- Q: Can waterproofing membranes be installed on uneven surfaces?

- Yes, waterproofing membranes can be installed on uneven surfaces. In fact, one of the advantages of waterproofing membranes is their ability to conform to various irregularities and unevenness in the surface. These membranes are typically flexible and can be easily molded and adjusted to fit the contours of the substrate. Additionally, some waterproofing membranes have self-adhesive properties or can be applied with adhesives, allowing them to adhere to both smooth and uneven surfaces effectively. However, it is important to note that proper surface preparation is crucial for a successful installation. The surface should be clean, dry, and free from any loose materials or debris to ensure optimum adhesion and performance of the waterproofing membrane.

Send your message to us

EPDM Rubber Coiled Waterproof Membrane for Public

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords