Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPU raw materials:

1. various kinds

2. competitive price

3. 30 years of experience

4. stable quality

TPU raw materials:

1. Applications and cable specifications of TPU raw materials:

Used for water-resistant power cables, data cables, and spring wire.

2. Description of TPU raw materials:

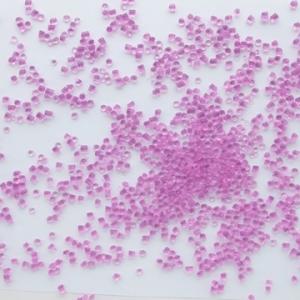

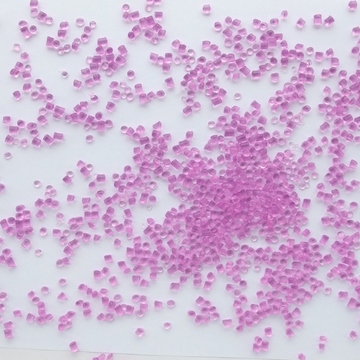

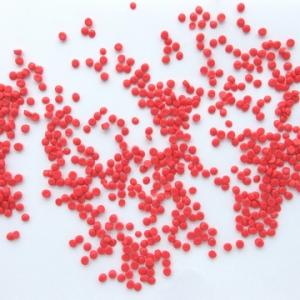

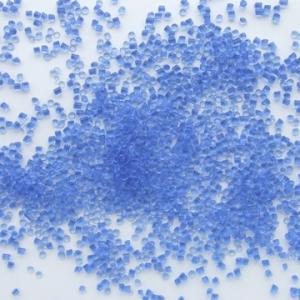

Environmental friendly halogen-free TPU cable compound, based on TPU elastomer resin, is made into granules by mixing, plastification and granulation with adding special modifier and other special additives. It has well performance of tenacity, scratch-resistant, flexibility, Stretch Resistance, and temperature resistance, owning exquisite appearance and smooth surface. It does not contain halogens and heavy metal, in line with the environmental directives of RoHS, REACH. Different hardness can be customized according to customers’ requirements.

3. Processing of TPU raw materials:

The compound can be processed with conventional extruders. It is recommended that the screw L/D should be greater than 25 and compression ratio should be 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Neck | Head | Die |

temperature °C | 150 | 170 | 155 | 175 | 178 | 178 | 175 |

Note:Compound should be dried at 80-90°C before use, which has stayed in storage more than one month.

4. Storage and transport of TPU raw materials:

Packaging:25kg/bag,Aluminum foil and PE film bag inside, and PP compound bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties of TPU raw materials:

Item | Unit | E7385 | E8385 | E8685 | E8685F | ||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.19 | -- | 1.21 | -- | 1.28 | -- | 1.27 |

Hardness | Shore A | -- | 85 | -- | 85 | -- | 85 | -- | 85 |

Tensile Strength | ≥MPa | 18 | 22 | 22 | 28 | 20 | 25 | 20 | 24 |

Elongation at Break | ≥ % | 550 | 700 | 500 | 650 | 500 | 650 | 450 | 600 |

Thermal aging | °C*h | 136°C*168h | 136°C*168h | 121°C*168h | 121°C*168h | ||||

TS retention | ≥ % | 75 | 103 | 75 | 105 | 75 | 104 | 75 | 102 |

EB retention | ≥ % | 75 | 81 | 75 | 84 | 65 | 89 | 65 | 86 |

Hot deformation | 150°C*4h | 150°C*4h | 150°C*4h | 150°C*4h | |||||

Variation on thermal deformation | ≤ % | 50 | 12 | 50 | 7 | 50 | 6 | 50 | 6 |

pH value of gases released | ≥ | 4.3 | 56. | 4.3 | 5.3 | ||||

Conductivity of Gases released | ≤μm/mm | 10 | 1.2 | 10 | 1.3 | ||||

Impact Brittleness Temperature | ≤ °C | -60 | Pass | -55 | Pass | -50 | Pass | -50 | Pass |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 2.1×1013 | 1.0×1013 | 5.2×1014 | 1.0×1013 | 3.4×1014 | 1.0×1013 | 1.8×1014 |

Flame retardant grade | UL94 2mm | V0 | pass | V0 | pass | ||||

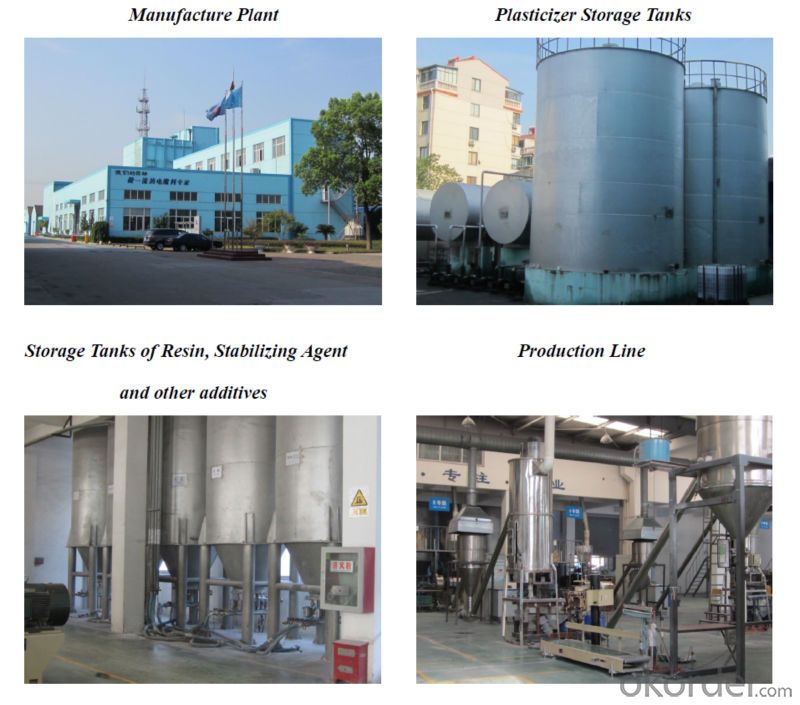

6. Company

- Q: What plastic material has great impact resistance?

- Plastic raw materials Linai the maximum impact strength is MC nylon, the impact strength was > 500 kg. L cm / cm, nylon 11 cm / cm - 380 kg. The impact strength of polycarbonate, poly (phenol oxide), F-46, poly phenol, Yaan, low pressure polyethylene, polypropylene and nylon 1010 unreinforced is continuous".

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q: Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the plastic barrel is 5, the main component of this kind of plastic barrel is polypropylene, or PP. The melting point of this kind of plastic barrel is relatively high, reaching 167 degrees centigrade, and can be recycled after cleaning. Compared to PE plastic barrels, PP plastic barrels of heat resistance slightly better, but the higher temperature there is the risk of softening and melting, use should avoid high temperature.

- Q: How many types of plastics are there?

- PC: commonly known as polycarbonate. The variety is also a transparent material, high surface hardness, scratch resistance, strong impact resistance, high strength, good weather resistance (that is not afraid of the sun). The furniture is the sunshine plate screen baffle material hollow extrusion molding. Features: high price cost, about PMMA higher than about 40%.

- Q: How many types of plastic materials are there?

- Plastic classification, composition and characteristics, plastic is a widely used synthetic polymer materials, in our daily life, plastic products abound. We wake up from the use of toiletries, the breakfast dishes, to work with the rest of the stationery, with cushions, mattresses, and TV, washing machine, computer shell, and night gave us the light of the lamps in various shapes...... Plastics have gradually replaced many materials and utensils that have been used for decades and centuries with their excellent performance, becoming an indispensable assistant in people's life. Plastic, metal in hard wood, light transparent glass ceramics, corrosion resistance, rubber elasticity and toughness in a body, in addition to daily necessities, plastic more widely used in aerospace, medical equipment, petroleum chemical industry, machinery manufacturing, defense, construction and other industries.

- Q: What are the plastic raw materials?

- This polymer is made up of many smaller and simpler molecules made of covalent bonds. There are many kinds of polymers, one is to change the Prajna heat to classification, it can be divided into two categories.

- Q: What raw materials do plastic color printing plants use?

- PEBOPPOPS film, aluminum film and so on, the ink is usually water-based ink, polypropylene ink, etc., different films with different ink.

- Q: What kind of plastic material is used for medical instruments?

- According to the use requirements of medical plastics, it is often necessary to make products with surface hydrophilicity, anti coagulation, radiation sterilization and other special functions.

- Q: What is the raw material for producing corn starch plastic film?

- According to the current technical level, the production of 1 tons of starch requires 1.5 tons of corn, power consumption of 200KWh, coal consumption of 0.3 tons. If the 1 tons of starch into biomass plastics, can be processed into 1.01.2 tons of products, instead of common plastics, saving petrochemical resources, the country. Because there is no effective stimulating mechanism in the downstream market, the application of corn starch is still limited to the research area of modified starch. The industrialization of biomass plastics with corn starch as the main raw material will effectively stimulate the cultivation of corn and the production of cornstarch. Biomass plastics are gradually evolved from the further research and development of biodegradable plastics. It is gradually recognized that only by fully utilizing the natural and recyclable plant resources to develop and develop biomass plastics is a reliable way to achieve sustainable economic development. In the past 30 years, and in half a century, all countries in the world pay attention to and invest a lot of manpower and material resources of biomass plastics, mainly starch and biodegradable plastics mixing, carbon dioxide copolymer, biosynthesis of biodegradable plastics, and then generate a biosynthetic precursor chemical polymerization of biodegradable plastics in 4 categories. The latter three prices are higher, but the cost is higher, mainly used in medical materials, biomedical engineering and tissue engineering and other high-value products.

- Q: Is plastic raw material rubber?

- The difference between the plastic and the rubber is plastic or not, but because of thermosetting plastics, this definition is not comprehensive. Another difference is whether the elastic body, but because of the appearance of thermoplastic elastomer, this definition is not comprehensive. In general, rigid high molecular material thermoplastic processing, sure is a plastic elastomer; and thermosetting rubber must be classified. The more ambiguous reference history. Silicone rubber and polyurethane is thermosetting elastomer rubber, is, but completely different from natural rubber. There is a part of polyurethane is thermosetting plastics, even thermoplastics, composition, structure and it depends on the characters.

Send your message to us

Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords