24 Inch Aluminum Coil - EN AW-5383 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

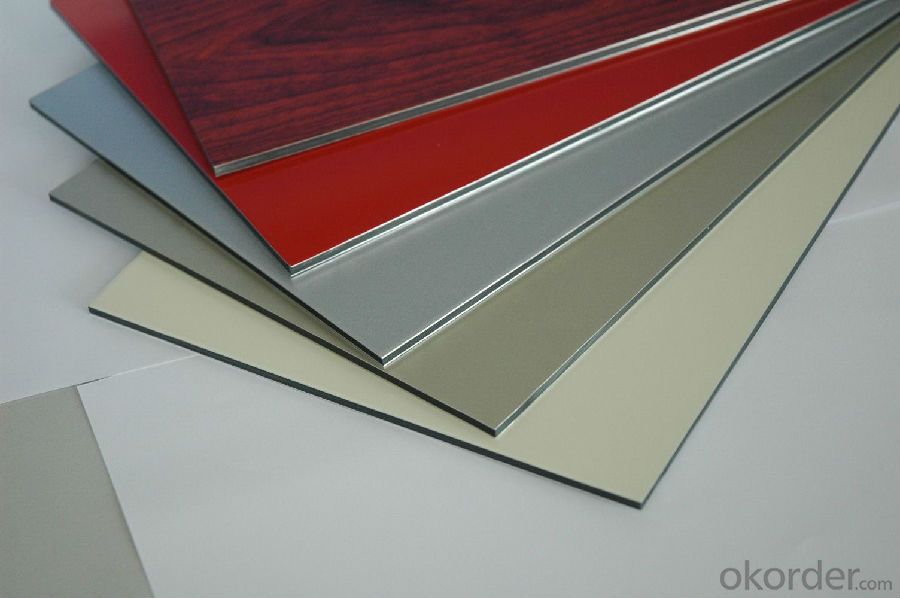

1. Structure of EN AW - 5383 PE Prepainted Aluminium Composite Panel

EN AW - 5383 PE Prepainted Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5383 PE Prepainted Aluminium Composite Panel

EN AW - 5383 PE Prepainted Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5383 PE Prepainted Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5383 PE Prepainted Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5383 PE Prepainted Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

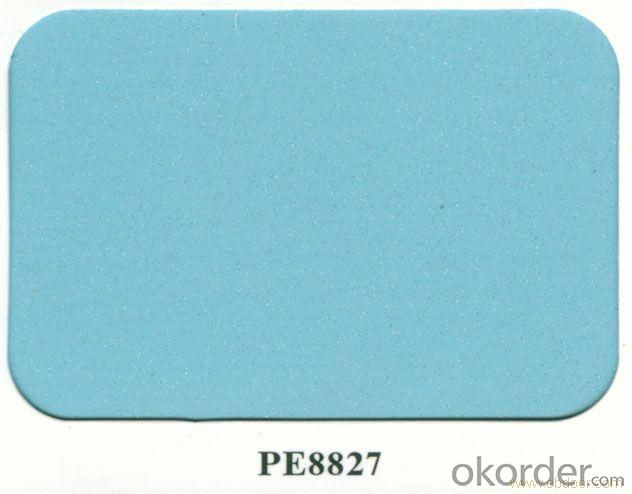

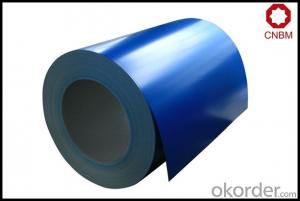

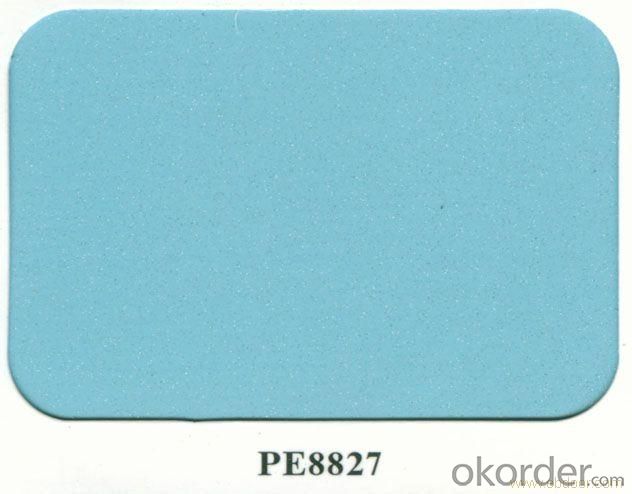

6. Image of EN AW - 5383 PE Prepainted Aluminium Composite Panel

7. Package and shipping of EN AW - 5383 PE Prepainted Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Two days ago, my cocker spaniel ate most of a small aluminum bread pan--the disposable kind you can buy in the supermarket. The pieces I picked up when I discovered what he'd done were sharp, so I called the vet (right before closing), who recommended just keeping an eye on him for nausea, diarrhea, etc. The next morning I brought the dog and he showed no discomfort, but the vet put him on an antibiotic (esp. for gastric problems) just in case. It's been 48 hours, and the dog's still happy and eating and drinking, and when we go for a walk, his poo is fine (yep; I examine it!) ... if he's passed the aluminum, it must have been in the back yard when he was out on his own, and not on a walk. However, I'm still very anxious. At what point can I draw a sigh of relief? Thank you!

- my dog ( a 90 lb weimeraner ) has eaten alot of foil....I think he likes it ....dont worry. Of course consult your vet if you think anything is wrong. If he's eating ( and esp. drinking ) I'd say he's ok. They are amazing animals.

- Q: This question asks for methods to assess the quality of aluminum coil, which is important in industries where aluminum products are used.

- <p>To check the quality of aluminum coil, you should inspect its surface for any defects like scratches, dents, or discoloration. Measure its thickness and width to ensure they meet the specified standards. Test its mechanical properties, such as tensile strength and elongation, to verify its strength and flexibility. Conduct a chemical analysis to confirm the alloy composition and purity. Check for any impurities or inclusions that could affect performance. Finally, assess the coil's flatness and straightness to ensure it's suitable for further processing.</p>

- Q: What are the different alloys used for aluminum coils?

- Aluminum coils utilize several different alloys, each possessing unique properties and applications. Some commonly employed alloys encompass: 1. 1100 Alloy: A pure aluminum alloy that boasts exceptional corrosion resistance and high thermal conductivity. It finds frequent usage in scenarios necessitating elevated thermal or electrical conductivity, such as heat exchangers or electrical conductors. 2. 3003 Alloy: A versatile aluminum alloy offering commendable resistance against atmospheric corrosion and moderate strength. It is commonly employed in situations requiring moderate strength and formability, like packaging, roofing, or vehicle parts. 3. 5052 Alloy: Among the strongest non-heat-treatable aluminum alloys, this alloy exhibits top-notch corrosion resistance and favorable formability. It frequently finds application in marine environments, automotive components, and household appliances. 4. 6061 Alloy: A heat-treatable aluminum alloy renowned for its exceptional strength and corrosion resistance. It is often utilized in structural capacities, such as aircraft components, marine hardware, or bicycle frames. 5. 7075 Alloy: A high-strength aluminum alloy recognized for its outstanding fatigue strength. It is commonly employed in aerospace and military scenarios, as well as in high-stress structural elements. These examples represent merely a fraction of the diverse array of alloys employed for aluminum coils. The selection of a specific alloy depends on the desired properties and intended application of the coil.

- Q: Are aluminum coils suitable for electrical conductors?

- Aluminum coils, indeed, prove to be suitable for electrical conductors. Due to its remarkable electrical conductivity, aluminum has become a widely utilized material in the electrical industry. It possesses approximately 61% conductivity in comparison to copper, the utmost commonly employed metal for electrical conductors. Lightweight, cost-effective, and possessing good thermal conductivity, aluminum coils have become a favored selection for a range of electrical applications. Nonetheless, it is noteworthy that aluminum has a lower tensile strength than copper, thus potentially demanding a larger cross-sectional area to attain an equivalent level of current carrying capacity. Furthermore, to prevent oxidation and guarantee efficient electrical conductivity in aluminum coils, it is imperative to employ proper insulation and connectors.

- Q: What is the acceptable range of temperatures for aluminum coils in terms of their functionality and durability?

- <p>The temperature range for aluminum coils can vary depending on the specific application and alloy type. Generally, aluminum coils can operate effectively within a range of -200掳F to 500掳F (-129掳C to 260掳C). For most industrial applications, the working temperature is between -40掳F to 300掳F (-40掳C to 150掳C). However, it's important to consult the manufacturer's specifications for the exact temperature limits of a particular aluminum coil, as these can differ based on the alloy and intended use.</p>

- Q: where is aluminum found in the world or in the universe?do u think aluminum is more valuable to people than gold?why or why not?im just lazy to look up the answers and person 4 best answer 10points

- where is aluminum found in the world aluminum is in fact the third most common element in the Earth's crust, and it is the most common metallic element on Earth. In a pure form, aluminum is silvery white and extremely lightweight. aluminum is more valuable to people than gold? aluminum continues to remake the modern world. We can see it everywhere; in architecture, transportation, electrical cables, communications and consumer products. Because it’s light-weight, strong, versatile and easy to recycle, aluminum is becoming more and more valuable in our daily lives melting point and boiling point Melting Point: 933.437 K (660.323°C or 1220.581°F) Boiling Point: 2792 K (2519°C or 4566°F)

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: Can aluminum coils be used for window frames?

- Certainly, window frames can indeed be made using aluminum coils. Aluminum is widely favored for window frames owing to its enduring nature, lightweight composition, and ability to resist corrosion. It is extensively employed in both residential and commercial settings. Aluminum coils can be effortlessly molded and adjusted to accommodate diverse window dimensions and designs. Additionally, aluminum frames provide exceptional thermal insulation qualities, thereby enhancing energy efficiency in structures. All in all, aluminum coils represent a dependable and pragmatic choice for constructing window frames.

- Q: What types of aluminum coil are best suited for specific applications?

- <p>Yes, different types of aluminum coil are better suited for specific applications. For instance, 1100 series aluminum coil, known for its high purity and excellent formability, is ideal for applications requiring deep drawing or bending. The 3003 series is often used for applications needing good corrosion resistance and formability, such as automotive parts and chemical equipment. The 5052 series offers a balance of strength and corrosion resistance, making it suitable for marine applications and aircraft structures. The 6061 series is known for its strength and is often used in construction and transportation industries. Each series has unique properties that make it more suitable for certain applications, so selection should be based on the specific requirements of the project.</p>

- Q: Can aluminum coils be used in electrical applications?

- Indeed, aluminum coils possess the capability for utilization in electrical applications. Its abundance in electrical wiring is attributable to its cost-effectiveness and superior conductivity in comparison to copper. Transformers, motors, generators, and other electrical apparatuses commonly rely on aluminum coils. Nevertheless, it is essential to acknowledge that copper surpasses aluminum in terms of electrical conductivity, necessitating the use of larger aluminum coils to attain equivalent levels of conductivity. Moreover, the implementation of specialized insulation and connectors becomes imperative for aluminum coils to prevent corrosion and guarantee appropriate electrical connections.

Send your message to us

24 Inch Aluminum Coil - EN AW-5383 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords