Coil Aluminum EN AW-4017 PVDF Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

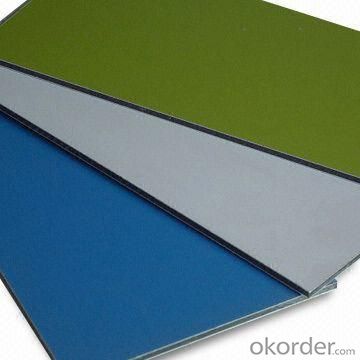

1. Structure of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

EN AW - 4017 PVDF Prepainted Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

EN AW - 4017 PVDF Prepainted Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

7. Package and shipping of EN AW - 4017 PVDF Prepainted Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different edge treatments available for aluminum coils?

- There are several different edge treatments available for aluminum coils, each with its own unique advantages and applications. 1. Mill Finish: This is the most basic edge treatment, where the edges of the aluminum coil are left as they are after the manufacturing process. This treatment is typically used for applications where aesthetics are not a priority, such as industrial or construction applications. 2. Trimmed Edge: In this treatment, the edges of the aluminum coil are trimmed to remove any sharp or jagged edges. This ensures safer handling and reduces the risk of injury during fabrication or installation. 3. Deburred Edge: Similar to the trimmed edge treatment, the deburred edge involves removing any burrs or sharp edges from the coil's edges. This is particularly important for applications where the aluminum coil will come into contact with other materials or surfaces, as it helps to prevent scratches or damage. 4. Rolled Edge: With this treatment, the edges of the aluminum coil are rolled to create a smooth, rounded edge. This not only enhances the overall appearance of the coil but also provides added protection against corrosion and damage. 5. Beveled Edge: In a beveled edge treatment, the edges of the aluminum coil are cut at an angle to create a sloping edge. This is often used in architectural applications where a sleek and modern look is desired. The beveled edge can also facilitate easier welding or joining of the aluminum coil. 6. Hemmed Edge: This treatment involves folding or bending the edges of the aluminum coil to create a hem-like finish. Hemmed edges provide increased strength and rigidity to the coil, making it suitable for applications that require added durability or structural integrity. 7. Painted or Powder Coated Edge: In this treatment, the edges of the aluminum coil are painted or powder coated to match the color or finish of the rest of the coil. This is commonly done to achieve a seamless and uniform appearance in applications where the coil's edges are visible. Overall, the choice of edge treatment for aluminum coils depends on the specific requirements of the application, including both functional and aesthetic considerations.

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum is a lightweight and corrosion-resistant material that has excellent thermal conductivity. These properties make it suitable for various applications where low-friction is desired. In industries such as automotive, aerospace, and HVAC systems, aluminum coils are often used in heat exchangers, evaporators, condensers, and cooling coils. These coils are designed to efficiently transfer heat, while minimizing friction and energy loss. Additionally, aluminum coils can be used in electrical motors, generators, and transformers, where low friction is essential for smooth operation and reduced energy consumption. The lightweight nature of aluminum also helps to reduce the overall weight of the system, leading to improved efficiency. Furthermore, aluminum coils can be utilized in various types of machinery and equipment that require low friction, such as conveyor systems, sliding mechanisms, and bearings. Aluminum's low coefficient of friction allows for smooth and efficient movement, minimizing wear and tear on the components. Overall, aluminum coils are a versatile solution for low-friction applications due to their lightweight, corrosion-resistant, and thermally conductive properties. Their use can lead to improved energy efficiency, reduced maintenance costs, and enhanced performance in a wide range of industries.

- Q: Can aluminum coils be used in the production of aluminum composite walls?

- Yes, aluminum coils can be used in the production of aluminum composite walls. Aluminum composite walls are typically made by sandwiching a layer of polyethylene between two aluminum sheets. The aluminum coils are first processed to form flat aluminum sheets, which are then used as the outer layers of the composite wall. The coils are unrolled and flattened during the manufacturing process to create the desired width and thickness of the aluminum sheets. These aluminum sheets offer excellent strength, durability, and weather resistance, making them ideal for use in aluminum composite walls. Additionally, the use of aluminum coils allows for efficient and cost-effective production, as they can be easily processed and formed into the required dimensions.

- Q: What are the different coil recoiling options available for aluminum coils?

- There are several coil recoiling options available for aluminum coils, depending on the specific requirements and desired outcomes. One option is the oscillate recoiling method, which involves winding the aluminum coil in a zigzag pattern. This technique helps to reduce coil set and improve flatness, making it suitable for applications where a flat, smooth surface is crucial. Another option is the traverse winding method, which involves winding the aluminum coil back and forth in a controlled manner. This technique helps to evenly distribute the tension across the coil, reducing the risk of coil breaks and ensuring consistent performance. Additionally, there are options for coil slitting and rewinding. Slitting involves cutting the aluminum coil into narrower strips, which can be rewound into smaller coils. This option is commonly used when smaller coil sizes are required for specific applications. Furthermore, some recoiling options include coil rewinding with tension control systems. These systems ensure that the tension applied during rewinding is controlled and consistent, helping to prevent overstretching or deformation of the aluminum coil. Overall, the choice of coil recoiling options for aluminum coils depends on factors such as the desired surface finish, coil size requirements, and specific application needs. Manufacturers and processors of aluminum coils can provide guidance and expertise in selecting the most suitable recoiling option based on these considerations.

- Q: How are aluminum coils used in the production of signage and displays?

- Due to their versatility, durability, and cost-effectiveness, aluminum coils find extensive use in the manufacturing of signage and displays. These coils are typically composed of high-quality aluminum alloy, which provides excellent strength and resistance against corrosion. To achieve the desired thickness and shape, the production process starts by unwinding the aluminum coils and passing them through a series of rollers. This process, known as coil coating or pre-painting, allows for the application of various finishes and coatings onto the aluminum's surface. The type of coating used, such as polyester, polyurethane, fluorocarbon, or acrylic, depends on the specific requirements of the signage or display. After the coating process, the aluminum coils can be further processed into different forms, including flat sheets, strips, or custom shapes based on the design specifications. Aluminum's versatility enables easy fabrication and customization, which makes it a popular choice among signage and display manufacturers. Aluminum coils are widely employed in various signage applications, such as billboards, outdoor advertising panels, trade show displays, store signage, and architectural signage. The lightweight nature of aluminum simplifies transportation and installation, reducing production and installation costs. Furthermore, the durability of aluminum ensures that signage and displays made from aluminum coils can withstand harsh weather conditions, UV radiation, and other environmental factors, making them suitable for both indoor and outdoor applications. Aluminum's resistance to corrosion also contributes to the long-lasting quality of the signage, allowing it to maintain its appearance and functionality over time. Apart from its physical properties, the aesthetic appeal of aluminum is another reason for its extensive use in signage and displays. The smooth and reflective surface of the metal provides an attractive finish that enhances the visual impact of the signage, effectively capturing attention and conveying messages. In conclusion, aluminum coils are essential in the production of signage and displays due to their versatility, durability, cost-effectiveness, and aesthetic appeal. The ease of customization, combined with the resistance to corrosion and harsh environmental conditions, makes aluminum an ideal material for creating visually striking and long-lasting signage and display solutions.

- Q: i've been looking all over the internet for this information and i cant fin it! please help!what is aluminum's isotopic notation?what is aluminum's density at room temperature with units?what is aluminum's most common oxidation # ?aluminums e-dot diagram? symbol with valence electronschemical equation?enviornmental concers?

- Aluminum is indeed very bad for us. I avoid drinking from aluminum cans and using foil. Also, anyone using a microwave should definitely use glass dishes that are microwave safe. It is important to never use plastic wrap or plastic dishes in the microwave because carcinogens are released when the plastic is heated up. It basically cooks the toxins right into your food.

- Q: Is it advisable to purchase and utilize recycled aluminum coils without initial quality assessment?

- <p>No, it is not safe to buy and use recycled aluminum coils without first checking their quality. Recycled aluminum coils may have inconsistencies in thickness, strength, and purity, which can affect the performance and safety of the final product. It's crucial to inspect the coils for any defects, impurities, or deviations from the required specifications to ensure they meet the standards necessary for your application. Quality control is essential to prevent failures, maintain safety, and uphold the integrity of your manufacturing process.</p>

- Q: How do aluminum coils contribute to energy-efficient insulation?

- Aluminum coils play a crucial role in enhancing energy-efficient insulation in various ways. Firstly, aluminum is an excellent conductor of heat, meaning it can effectively transfer heat away from the source, reducing the amount of heat that penetrates into the insulated space. This property helps to maintain a stable and comfortable indoor environment while minimizing the need for excessive heating or cooling. Additionally, aluminum coils are often utilized in the construction of air conditioning and refrigeration systems, where they act as the heat transfer medium. By efficiently absorbing and dissipating heat, these coils enable the system to cool down the air more rapidly, thus reducing energy consumption and enhancing overall energy efficiency. Moreover, aluminum is a lightweight material, which makes it easier to handle and install in insulation systems. This lightweight characteristic allows for more flexibility and ease of transportation during the manufacturing and installation processes, resulting in cost and energy savings. Furthermore, aluminum coils are highly corrosion-resistant, ensuring their longevity and preventing the degradation of insulation performance over time. This durability translates into long-term energy efficiency, as the insulation system remains effective for an extended period without requiring frequent maintenance or replacement. In summary, aluminum coils contribute to energy-efficient insulation by efficiently conducting heat, facilitating rapid cooling in air conditioning systems, reducing energy consumption, being lightweight and easy to handle, and providing long-lasting performance due to their corrosion resistance. These characteristics make aluminum coils a favorable choice for enhancing energy efficiency in insulation applications.

- Q: A bit of a question for the 1911 experts roaming around here. Per-say someone, who knew their way around a 1911 built one on an aluminum frame. To top it all off, if the finished gun were to be chambered in .38 super... how long would this combination last? I've heard horror stories about aluminum frames, and then I've heard some wonderful things... this question was to see if anyone had ever thought about/done this sort of thing before. Something tells me that Aluminum + .38 super wouldn't last too long... Most informative answer gets the ten point prize as usual.

- Well you have to take your pick from two solutions: One get a steel frame which is heavier but stronger and can handle higher pressure loads, or an aluminum which is lighter but of a lower strength. What loads are you putting through it, how much are you using it, basic things like that. If you are constantly going to be shooting high powered loads through it, go with steel, if you are only going to use it as a race gun, still go with steel, aluminum is crap it deforms and decreases accuracy and jams much more often then steel.

- Q: having trouble looking for tis information, don't know where to look.Is aluminum accessible to everyone?? Does it cost a lot, is it in minimal areas if so is it hard to transport to all around the world??

- the same way steel does s it is very different in a bunch of way

Send your message to us

Coil Aluminum EN AW-4017 PVDF Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords