3000 Series Painted Aluminum Coil - EN AW-5052 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

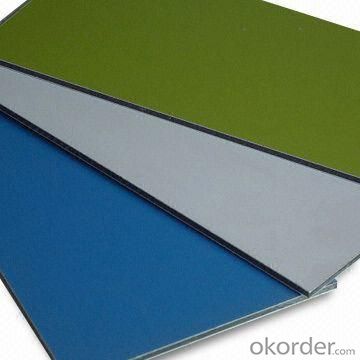

1. Structure of EN AW - 5052 PE Prepainted Aluminium Composite Panel

EN AW - 5052 PE Prepainted Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5052 PE Prepainted Aluminium Composite Panel

EN AW - 5052 PE Prepainted Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5052 PE Prepainted Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5052 PE Prepainted Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5052 PE Prepainted Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

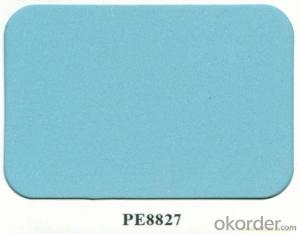

6. Image of EN AW - 5052 PE Prepainted Aluminium Composite Panel

7. Package and shipping of EN AW - 5052 PE Prepainted Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do I deal with too much aluminum powder when the aluminum strips are divided?

- Because of low maintenance costs, the former favored by enterprises, accounting for more than 90% of all dust removal systems, but often there will be a problem: ventilation and dust removal system is not strictly in accordance with the specifications to do, resulting in dust accumulation.

- Q: How are aluminum coils joined in a continuous process?

- Aluminum coils are joined in a continuous process using various techniques such as welding, brazing, and adhesive bonding. Welding is a common method used to join aluminum coils together. It involves melting the edges of the coils and then fusing them together. This can be achieved through various welding processes such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or laser welding. These methods provide a strong and durable bond between the coils. Brazing is another technique used for joining aluminum coils. It involves heating the coils and using a filler material with a lower melting point than the aluminum to create the joint. The filler material, often a brazing alloy, is applied to the joint area, and when heated, it melts and flows into the gap between the coils, forming a solid bond upon cooling. Adhesive bonding is also employed in the continuous joining of aluminum coils. This method involves applying a specialized adhesive or glue to the surfaces of the coils that need to be joined. The adhesive is carefully selected to have excellent bonding properties with aluminum. The coils are then pressed together, and the adhesive cures, creating a strong and reliable bond. Each joining technique has its advantages and is chosen based on factors such as the application requirements, the type of aluminum being used, and the desired level of strength and durability. The choice of joining method in a continuous process depends on the specific needs of the production line and the final product.

- Q: Are there any limitations or restrictions on the use of aluminum coils?

- Yes, there are limitations and restrictions on the use of aluminum coils. Some of the limitations include the maximum operating temperature, which is typically lower compared to other metals, such as copper. Aluminum coils may also have lower electrical conductivity, making them unsuitable for certain applications that require high conductivity. Additionally, the corrosion resistance of aluminum coils can be compromised in certain environments, necessitating protective coatings or alternative materials. Lastly, the strength and durability of aluminum coils may be lower compared to other materials, which may limit their use in certain high-stress applications.

- Q: How do aluminum coils contribute to lightweight vehicle design?

- Due to their unique properties and manufacturing processes, aluminum coils play a crucial role in the attainment of lightweight vehicle designs. Aluminum, being a lightweight material itself and weighing only about one-third of steel, is an ideal choice for lightweight vehicle design. When aluminum is formed into coils, it offers various advantages that contribute to the overall reduction in vehicle weight. First and foremost, aluminum coils possess high formability, enabling the creation of complex shapes using less material. This characteristic allows automakers to design intricate body panels and structural components that are both lightweight and possess improved aerodynamics and fuel efficiency. The ability to shape aluminum coils intricately also provides increased flexibility in design, leading to more innovative and visually appealing vehicle designs. Secondly, aluminum coils exhibit an exceptional strength-to-weight ratio, making them an excellent option for structural components. Despite their lightweight nature, aluminum coils provide exceptional structural integrity, ensuring the safety and durability of the vehicle. By incorporating aluminum coils into the chassis, suspension systems, and other critical components, automakers can reduce weight while maintaining the necessary strength and rigidity required for safe operation. Moreover, aluminum coils possess excellent corrosion resistance, which is vital for the long-term longevity of the vehicle. Corrosion can significantly impact the structural integrity and overall performance of a vehicle. By utilizing aluminum coils, automakers can minimize the risk of corrosion-related issues, resulting in a longer lifespan for the vehicle and reduced maintenance costs. Lastly, the utilization of aluminum coils aids in the overall reduction of vehicle weight, leading to improved fuel efficiency and decreased greenhouse gas emissions. Lighter vehicles require less energy for acceleration and to maintain speed, resulting in enhanced fuel economy. This benefit becomes increasingly significant as the automotive industry strives to develop more sustainable and eco-friendly vehicles. In conclusion, aluminum coils make a significant contribution to the design of lightweight vehicles by offering high formability, exceptional strength-to-weight ratio, corrosion resistance, and overall weight reduction. These properties enable automakers to design vehicles that are not only lighter but also safer, more fuel-efficient, and visually appealing. As the demand for lightweight vehicles continues to rise, aluminum coils play a vital role in achieving these design objectives.

- Q: How are aluminum coils tested for flatness?

- Various methods are employed to test the flatness of aluminum coils, guaranteeing their compliance with the necessary standards. One commonly used approach involves the utilization of a straight edge. In this method, a lengthy and meticulously precise straight edge is placed on the coil's surface. Technicians then visually inspect for any discrepancies or gaps between the straight edge and the coil. The presence of such gaps indicates that the coil is not flat, necessitating further examination. Another technique utilized is the straight edge ruler method. Here, a ruler with a thin and flexible edge is applied to the surface of the coil. By applying gentle pressure, technicians can identify any areas where the ruler fails to fully make contact with the coil, indicating irregularities in its flatness. Advanced methods, including laser or optical techniques, are also employed to assess the flatness of aluminum coils. These methods employ laser beams or optical sensors to measure the surface profile of the coil. The collected data is then analyzed to determine if there are any deviations from the desired flatness. These sophisticated techniques provide precise and accurate results, enabling a more comprehensive evaluation of the coil's flatness. In conclusion, the testing of aluminum coils for flatness is of utmost importance in ensuring that they meet the required standards for a variety of applications. By utilizing a combination of visual inspection, straight edge techniques, and advanced laser or optical methods, manufacturers can guarantee that the coils are flat and devoid of any irregularities that could impact their performance.

- Q: How are aluminum coils used in the production of signage and displays?

- Due to their versatility, durability, and cost-effectiveness, aluminum coils find extensive use in the manufacturing of signage and displays. These coils are typically composed of high-quality aluminum alloy, which provides excellent strength and resistance against corrosion. To achieve the desired thickness and shape, the production process starts by unwinding the aluminum coils and passing them through a series of rollers. This process, known as coil coating or pre-painting, allows for the application of various finishes and coatings onto the aluminum's surface. The type of coating used, such as polyester, polyurethane, fluorocarbon, or acrylic, depends on the specific requirements of the signage or display. After the coating process, the aluminum coils can be further processed into different forms, including flat sheets, strips, or custom shapes based on the design specifications. Aluminum's versatility enables easy fabrication and customization, which makes it a popular choice among signage and display manufacturers. Aluminum coils are widely employed in various signage applications, such as billboards, outdoor advertising panels, trade show displays, store signage, and architectural signage. The lightweight nature of aluminum simplifies transportation and installation, reducing production and installation costs. Furthermore, the durability of aluminum ensures that signage and displays made from aluminum coils can withstand harsh weather conditions, UV radiation, and other environmental factors, making them suitable for both indoor and outdoor applications. Aluminum's resistance to corrosion also contributes to the long-lasting quality of the signage, allowing it to maintain its appearance and functionality over time. Apart from its physical properties, the aesthetic appeal of aluminum is another reason for its extensive use in signage and displays. The smooth and reflective surface of the metal provides an attractive finish that enhances the visual impact of the signage, effectively capturing attention and conveying messages. In conclusion, aluminum coils are essential in the production of signage and displays due to their versatility, durability, cost-effectiveness, and aesthetic appeal. The ease of customization, combined with the resistance to corrosion and harsh environmental conditions, makes aluminum an ideal material for creating visually striking and long-lasting signage and display solutions.

- Q: Dongying power plant with 0.6mm thick insulation aluminum coil, manufacturers can be divided into small volumes?

- How wide is the inside diameter of an aluminum roll; a roll of multiple. Small volume of MOQ is required.

- Q: How heavy and long is the aluminum rolling on average?

- On average it is 5 or 6 tons, and you can weigh specific ones. The length = weight/(width*thickness*density).

- Q: I need ideas on soundproofing a 12' aluminum fishing boat?

- The ULTIMATE way to soundproof and line your boat is with that stuff they cover the bed of pick-up trucks. Cabelas sells a kit you paint on. It works great! Call Cabelas, it's only $50, and it works and looks professional!

- Q: What are the typical lead times for aluminum coil orders?

- The typical lead times for aluminum coil orders can vary depending on the supplier and their current production capacity. However, it is common to expect lead times ranging from a few weeks to a couple of months for standard aluminum coil orders. It is advisable to contact the specific supplier for more accurate and up-to-date lead time information.

Send your message to us

3000 Series Painted Aluminum Coil - EN AW-5052 PE Prepainted Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords