Aluminum PE Prepainted Aluminium Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PE Prepainted Aluminium Composite Panels Description

PE Prepainted Aluminium Composite Panels is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PE Prepainted Aluminium Composite Panels

PE Prepainted Aluminium Composite Panels | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of PE Prepainted Aluminium Composite Panels

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PE Prepainted Aluminium Composite Panels

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PE Prepainted Aluminium Composite Panels

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

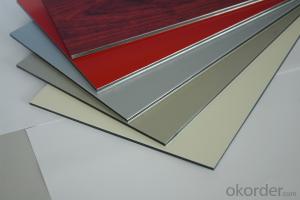

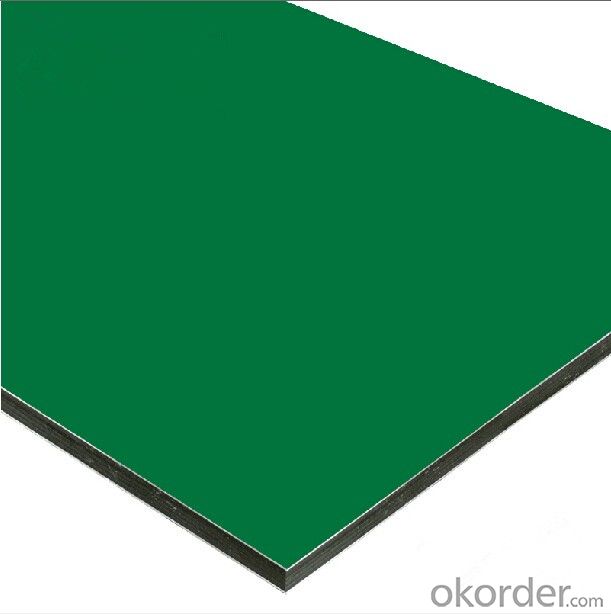

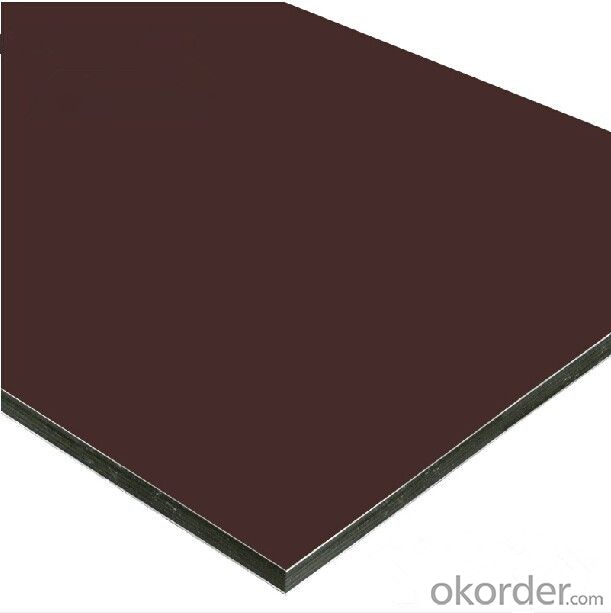

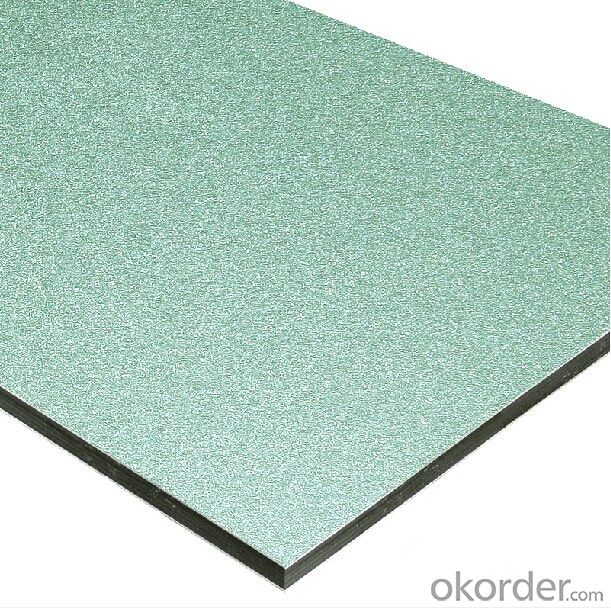

6. Image of PE Prepainted Aluminium Composite Panels

7. Package and shipping of PE Prepainted Aluminium Composite Panels

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What other materials can be used for food packaging besides aluminum?

- <p>Alternative materials to aluminum for food packaging include biodegradable plastics such as PLA (Polylactic Acid), paper-based materials, glass, and stainless steel. Biodegradable plastics are derived from renewable resources and break down over time. Paper-based materials are sustainable and can be recycled. Glass is a non-porous material that is excellent for preserving food quality and is also recyclable. Stainless steel is durable, reusable, and does not react with food, making it a popular choice for reusable containers. Each material has its own set of advantages and disadvantages, and the choice depends on factors like food type, shelf life, and environmental impact.</p>

- Q: Is aluminum suitable for use in paint and coating applications?

- <p>Yes, aluminum can be used in paints and coatings. It is often used in the form of aluminum pigments or flakes, which provide a metallic appearance and enhance the durability and corrosion resistance of the coating. Aluminum pigments are also valued for their ability to reflect light and heat, making them useful in applications requiring thermal insulation or reflective properties. Additionally, aluminum can be used in powder coatings, providing a hard, wear-resistant finish.</p>

- Q: Is it safe and practical to use old aluminum cookware that has been stored for a long time?

- <p>Yes, you can reuse old aluminum cookware, but it's important to check its condition first. Look for any signs of damage, such as pits, scratches, or warping, as these can affect the cookware's performance and potentially release aluminum into your food. If the cookware is in good condition, clean it thoroughly and season it if necessary. Remember, aluminum cookware is not suitable for acidic foods or high heat, so use it accordingly to prolong its lifespan and maintain food safety.</p>

- Q: This question asks about the methods to determine the safety of a specific brand's aluminum products.

- <p>To determine if a particular brand of aluminum products is safe to use, one should look for certifications and standards compliance. Check if the brand has certifications such as ISO 9001 for quality management systems or specific safety certifications relevant to aluminum products. Look for compliance with safety standards like ANSI, ASTM, or EN standards. Additionally, research customer reviews and testimonials, and consider third-party lab testing results. It's also important to inquire about the manufacturing process to ensure it adheres to environmental and health safety regulations. Lastly, consult with industry experts or regulatory bodies for their assessment of the brand's safety practices.</p>

- Q: Is it safe and effective to use aluminum foil to create a sandwich in a microwave oven?

- <p>No, you should not use aluminum foil to make a sandwich in a microwave oven. Aluminum foil can cause sparks and potentially start a fire due to its reflective properties and the microwave's electromagnetic radiation. It can also damage the microwave's interior. Instead, use microwave-safe containers or wraps designed for microwaving.</p>

- Q: This question asks about the amount of energy needed to produce aluminum, including the process and factors that influence energy consumption.

- <p>Producing aluminum requires a significant amount of energy, primarily due to the electrolytic process used to extract it from its ore, bauxite. The Hall-H茅roult process, the most common method, consumes about 15,000 to 16,000 kilowatt-hours of electricity per ton of aluminum produced. This high energy demand is largely due to the strong chemical bonds in aluminum oxide, which must be broken to release the aluminum. Energy consumption can vary based on the efficiency of the smelting process, the quality of the bauxite, and the energy source used, with renewable energy potentially reducing the carbon footprint but not necessarily the total energy input.</p>

- Q: What specific rules or guidelines are there for incorporating aluminum in construction projects?

- <p>Yes, there are special regulations for using aluminum in construction projects. These regulations vary by country and region but generally include standards for material properties, structural integrity, fire resistance, and environmental impact. For instance, the American Society for Testing and Materials (ASTM) and the Aluminum Association provide guidelines for aluminum usage in construction. Compliance with building codes is crucial, and these codes often specify the grades of aluminum, allowable stress values, and methods of joining. Additionally, considerations for corrosion resistance, thermal expansion, and recycling potential are important. It's essential to consult local building codes and industry standards to ensure compliance when using aluminum in construction.</p>

- Q: This question asks about the general environmental impact of using aluminum.

- <p>The use of aluminum has both positive and negative environmental impacts. On the positive side, aluminum is lightweight and durable, which can reduce the energy needed for transportation. It is also recyclable, and recycling aluminum saves up to 95% of the energy required to produce new aluminum from raw materials. However, on the negative side, the production of aluminum is energy-intensive and generates significant greenhouse gas emissions. The process also produces toxic byproducts, such as fluorides, which can contaminate water and soil. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Overall, while aluminum has its benefits, its production and use have substantial environmental consequences that need to be managed responsibly.</p>

- Q: What are the primary applications and benefits of aluminum in various industrial sectors?

- <p>Aluminum is extensively used in the industry due to its lightweight, high strength, and excellent corrosion resistance. It is a key material in the aerospace industry for aircraft construction to reduce weight and improve fuel efficiency. In the automotive sector, aluminum is used for engine parts and body panels to enhance fuel economy and performance. The construction industry utilizes aluminum for window frames, roofing, and structural components due to its durability and low maintenance. Aluminum is also prevalent in the packaging industry for food and beverage cans, and in electrical applications for wiring and transformers due to its high conductivity. Its recyclability makes it an environmentally friendly choice, further enhancing its industrial applications.</p>

- Q: This question asks for a comparison between aluminum and magnesium, two common metallic elements, highlighting their differences.

- <p>Aluminum and magnesium are both lightweight metals with distinct properties. Aluminum is more abundant in the Earth's crust and is known for its high strength-to-weight ratio, making it ideal for construction and transportation. It is also a good conductor of heat and electricity. Magnesium, while also lightweight, is less dense and has a lower melting point than aluminum. It is highly reactive and is often used in alloys to increase strength and durability. Magnesium is also essential for biological processes and is commonly found in supplements. In terms of reactivity, magnesium is more reactive than aluminum, which makes it more prone to corrosion in certain environments.</p>

Send your message to us

Aluminum PE Prepainted Aluminium Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords