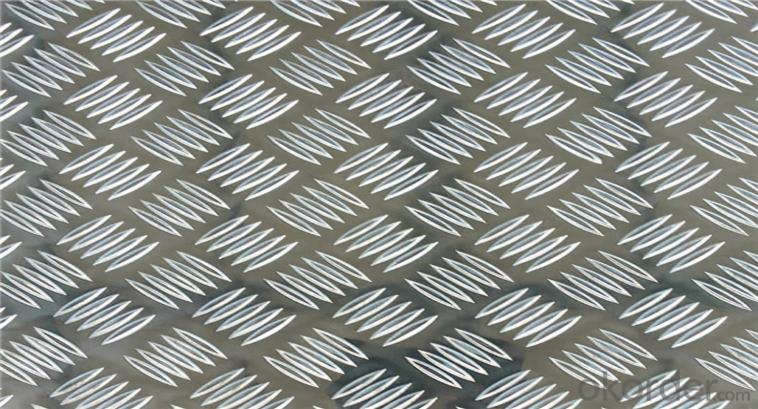

Five Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Five Bars Pattern Embossed Aluminum Sheet and Coil

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Uage/Application of Five Bars Pattern Embossed Aluminum Sheet and Coil

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Five Bars Pattern Embossed Aluminum Sheet and Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

4. Production Flow of Five Bars Pattern Embossed Aluminum Sheet and Coil

Melting-Rolling- Cutting- Annealing--Packing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines. Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC.

- Q: Can the aluminum sheets be used for heat dissipation purposes?

- Yes, aluminum sheets can be used effectively for heat dissipation purposes due to their excellent thermal conductivity.

- Q: How do aluminum sheets perform in extreme temperatures?

- Aluminum sheets generally perform well in extreme temperatures as they have a high melting point and excellent thermal conductivity. This allows them to resist deformation or structural changes under extreme heat or cold conditions. Additionally, aluminum has a low coefficient of expansion, which helps it maintain its shape and integrity under temperature fluctuations. Overall, aluminum sheets are known for their stability and reliability even in extreme temperature environments.

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: Could copper wire be welded with aluminum sheet?

- Copper wire could be welded with aluminum sheet, and it needs to use low temperature welding method, if copper wire is in the unit of millimeter and aluminum sheet is also in the unit below 1 mm, you can use electric soldering iron to heat it as hybrid welding and choose low temperature welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. As for the large aluminum sheet, you can take liquefied gas multihole lance as heat source, then choose the same low temperature materials as welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. Welding fundamentals of these two welding methods: both of them are use heatable heat source to heat the matrix to 179 degree, the melting point of WEWELDING M51, then use matrix’s heat conduction to melt welding wire, completing welding. The process of melting welding wire is the process of smearing the welding wire with flux into welding area, melting welding wire completely depends on matrix’s heat conduction.

- Q: Are 101 aluminum sheets easy to work with in terms of cutting, drilling, and shaping?

- Cutting, drilling, and shaping aluminum sheets is generally quite easy, especially when working with 101 aluminum. This alloy is known for its malleability and lightweight nature, making it more manageable compared to other metals. It offers good formability and weldability, making it suitable for various fabrication processes. To cut aluminum sheets, common tools such as saws, shears, or even a simple utility knife can be used. Similarly, drilling holes in aluminum sheets is relatively effortless and can be done using standard drill bits. Shaping aluminum sheets can be accomplished through bending, folding, or by utilizing specialized tools like a brake press. However, it is crucial to always prioritize safety and use appropriate measures and equipment when working with any metal, including aluminum.

- Q: How do you achieve a mirror-like finish on aluminum sheets?

- Achieving a mirror-like finish on aluminum sheets involves a series of steps to remove any imperfections and create a smooth, reflective surface. Here are the key processes involved: 1. Surface preparation: Start by thoroughly cleaning the aluminum sheet to remove any dirt, grease, or other contaminants using a mild detergent and water. Rinse and dry the surface completely. 2. Sanding: Use progressively finer grits of sandpaper or abrasive pads to remove any scratches, oxidation, or roughness on the aluminum surface. Begin with a coarser grit (around 120-180) and gradually move to finer grits (up to 1000 or higher) to achieve a smoother finish. Sanding should be done in a consistent direction to avoid creating visible scratches. 3. Polishing compounds: Apply a polishing compound or metal polish designed specifically for aluminum surfaces. Use a soft cloth or a buffing wheel to apply the polish and work it into the surface. Apply gentle pressure and move in circular motions to evenly distribute the polish. Repeat this step until the desired level of shine is achieved. 4. Buffing: Use a buffing wheel, preferably made of felt or cotton, to further enhance the shine. Apply a small amount of a high-quality polishing compound to the wheel and carefully buff the aluminum sheet in a consistent manner. Again, use circular motions and maintain a steady, even pressure. 5. Final polishing: To achieve a mirror-like finish, use a specialized aluminum polish or a metal finishing compound. Apply a small amount onto a clean cloth and gently rub the surface in circular motions. This final step helps remove any fine scratches or imperfections, adding a brilliant shine to the aluminum sheet. Remember to clean the aluminum sheet thoroughly after each step to remove any residue or excess polish. Additionally, always follow the manufacturer's instructions when using specific polishing compounds or tools, as they may have specific guidelines for optimal results. By following these steps carefully and patiently, you can achieve a mirror-like finish on aluminum sheets, transforming them into highly reflective surfaces that are both visually appealing and functional.

- Q: What is a composite aluminum plate?

- APCP (also called APCP) as a new type of decorative materials, since the last century at the end of 80s early 90s from South Korea to China, with its economy, optional color diversity, convenient construction method, excellent processing performance, excellent fire resistance and noble quality, quickly favored by people.Abroad, the name of aluminum plate has many kinds, there is called "aluminum composite board" (Aluminum Composite)Panels) there is called aluminum composite (Aluminum, Composite)Materials) in many European countries, the aluminum plate is Alucobond, a trademark derived from the aluminum-plastic plate. There are not many enterprises producing aluminum-plastic plate abroad, but the scale of production is very large. Well known are the Swiss based Alusuisse company and the Reynolds Metal Co in the United StatesJapan, Mitsubishi Co, Korea Daming, etc.. Taiwan auspicious, famous enterprises, Jiangxi Thailand, Alice Alex Hua Tian, Shanghai Huayuan, Ningbo aihome aluminum building materials.

- Q: This question asks for a list of various standard sizes of aluminum sheets that are commonly available in the market.

- <p>Aluminum sheet sizes can vary widely depending on the application and industry standards. Commonly available sizes include 1/8 inch, 1/4 inch, 3/8 inch, and 1/2 inch thicknesses, with widths ranging from 12 inches to 60 inches. Lengths can be from 4 feet to 20 feet or more. However, specific sizes can differ based on regional standards and manufacturers' offerings. It's also important to note that custom sizes can be ordered to meet specific project requirements. Always check with suppliers for the most current and detailed list of available sizes.</p>

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity, and it is commonly used in various electrical components and applications. Aluminum sheets are often used as conductive materials in power transmission lines, bus bars, and electrical enclosures. They are also utilized in the manufacturing of capacitors, transformers, and heat sinks due to their excellent thermal conductivity properties. Additionally, aluminum sheets are lightweight and corrosion-resistant, making them suitable for electrical applications where weight and durability are important factors.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

Send your message to us

Five Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords