Deformed Bars BS4449 B460B for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

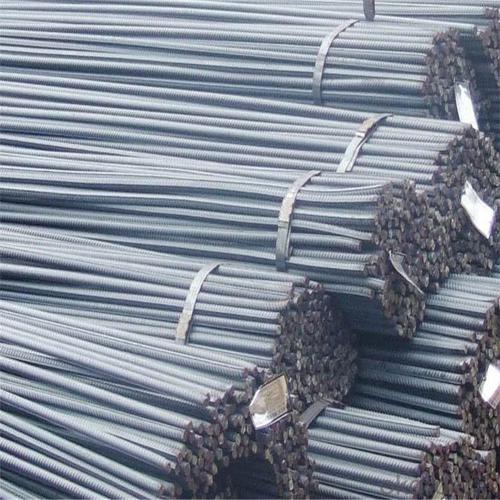

Deformed Bars BS4449 B460B for Construction

Description of Deformed Bars BS4449 B460B for Construction

1, Diameter: 5.5mm-10mm Deformed Bars BS4449 B460B for Constructionr

10m- 40mm Deformed Bars BS4449 B460B for Construction

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Deformed Bars BS4449 B460B for Construction

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Deformed Bars BS4449 B460B for Construction

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to reducing material waste?

- Special steel contributes to reducing material waste through its unique properties and manufacturing processes. Firstly, special steel is known for its high strength and durability, which allows for the creation of products that have a longer lifespan and require less frequent replacement. This reduces the amount of material waste generated from constantly discarding and replacing worn-out products. Moreover, special steel is often designed to be easily recyclable. Its composition and manufacturing techniques allow for efficient recycling, enabling the reuse of steel scrap and minimizing the need for new raw materials. This significantly reduces material waste by preventing the accumulation of discarded steel products in landfills. Additionally, special steel's versatility and customization options play a vital role in reducing material waste. By tailoring the steel's composition and properties to specific applications, manufacturers can optimize the use of materials and avoid unnecessary waste. Special steel's ability to be formed into complex shapes and sizes further enhances its efficiency, as it reduces the amount of excess material that would typically be wasted during the manufacturing process. In summary, special steel contributes to reducing material waste through its strength and durability, recyclability, and customization options. By promoting longer product lifespans, efficient recycling processes, and optimized material usage, special steel plays a crucial role in minimizing waste and promoting sustainability.

- Q: How are titanium alloys used in the medical industry?

- Titanium alloys are widely used in the medical industry due to their excellent biocompatibility, corrosion resistance, and high strength-to-weight ratio. These alloys are used for various medical applications such as implants, surgical instruments, and medical equipment. They are often used in orthopedic implants, dental implants, and cardiovascular devices, as they provide long-term stability and compatibility with the human body. Additionally, titanium alloys are highly resistant to bodily fluids and can withstand harsh sterilization processes, making them ideal for use in the medical field.

- Q: What grade of iron powder should be used for processing special steel? Are there any other elements on the request? How much are they?

- Special steel into high quality carbon steel, alloy steel, high alloy steel (alloy element is greater than 10%) three categories, including alloy steel and high alloy steel special steel production accounted for 70%.

- Q: What are the main corrosion resistance properties of special steel?

- The main corrosion resistance properties of special steel include high resistance to rust, oxidation, and chemical attack. It can withstand harsh environments, such as exposure to saltwater, acids, and alkalis, without significant degradation. Additionally, special steel often possesses a passive oxide layer on its surface, which acts as a protective barrier against corrosion.

- Q: What are the main applications of special steel in the chemical processing industry?

- Special steel is widely used in the chemical processing industry due to its unique properties and capabilities. Some of the main applications of special steel in this industry include the manufacturing of storage tanks, pipelines, and reactors. Special steel is resistant to corrosion, high temperatures, and chemical reactions, making it ideal for handling and storing various chemicals and substances. Additionally, special steel is also utilized in the construction of equipment used in the separation, purification, and filtration processes in chemical plants. Overall, the main applications of special steel in the chemical processing industry revolve around its durability, resistance to corrosion, and ability to withstand harsh chemical environments.

- Q: What are the different methods of preventing hydrogen-induced cracking in special steel?

- To prevent hydrogen-induced cracking in special steel, various methods can be utilized: 1. Preheating the steel prior to welding or any high-temperature process can lower the possibility of hydrogen-induced cracking. This technique slows down the cooling rate, allowing hydrogen to dissipate before causing any cracks. 2. Employing specific heat treatment processes like stress relieving or post-weld heat treatment helps alleviate hydrogen-induced cracking. These processes decrease residual stresses and facilitate hydrogen diffusion, minimizing the risk of cracking. 3. Opting for steel alloys with higher resistance to hydrogen-induced cracking is an effective preventive measure. Certain steel compositions, such as low carbon or low alloy steels, demonstrate reduced susceptibility to cracking in the presence of hydrogen. 4. Ensuring proper control of hydrogen during welding is crucial. This can be achieved by utilizing low-hydrogen welding consumables, such as electrodes, and guaranteeing adequate shielding gas coverage to prevent atmospheric moisture from contaminating the weld. 5. Managing stress on the steel during welding or operation is essential in preventing cracking. This can be accomplished by employing appropriate welding techniques, such as avoiding excessive heat input or rapid cooling rates, and minimizing the introduction of tensile stresses during welding. 6. Applying protective coatings or surface treatments acts as a barrier against hydrogen absorption, reducing the risk of hydrogen-induced cracking. 7. Optimizing the welding parameters, including current, voltage, and travel speed, can help reduce the chances of hydrogen-induced cracking. Adjusting these parameters allows control over heat input and cooling rate, thus minimizing hydrogen absorption and subsequent cracking. It is important to note that a combination of these preventive measures is often necessary to effectively mitigate the risk of hydrogen-induced cracking in special steel. Additionally, implementing proper inspection and quality control procedures is crucial to ensure the integrity of the steel and detect any cracks or defects.

- Q: What are the different carburizing techniques used for special steel?

- There are several carburizing techniques used for special steel, including gas carburizing, pack carburizing, liquid carburizing, and vacuum carburizing. Each technique involves introducing carbon into the surface of the steel to enhance its hardness and wear resistance. Gas carburizing involves heating the steel in a controlled atmosphere of carbon-rich gas, while pack carburizing entails surrounding the steel with a mixture of carbon-rich material and heating it. Liquid carburizing involves immersing the steel in a bath of molten salts or other carbon-rich liquid, and vacuum carburizing utilizes a low-pressure environment to introduce carbon into the steel's surface. These techniques are chosen based on the specific requirements of the steel and the desired end properties.

- Q: How is special steel used in the manufacturing of industrial machinery?

- Special steel is used in the manufacturing of industrial machinery due to its exceptional strength, durability, and resistance to high temperatures and corrosion. It is commonly employed to create components such as gears, shafts, bearings, and tools, ensuring optimal performance and longevity of the machinery in demanding industrial environments.

- Q: How does the heat treatment process affect special steel?

- The heat treatment process greatly affects special steel by altering its microstructure and improving its mechanical properties. It involves heating the steel to a specific temperature and then cooling it in a controlled manner. This process can increase the steel's hardness, strength, toughness, and wear resistance, making it suitable for various applications in industries such as automotive, aerospace, and tool manufacturing. Additionally, heat treatment can also enhance the steel's dimensional stability and corrosion resistance, further improving its overall performance.

- Q: How does special steel contribute to the aviation industry?

- Special steel contributes to the aviation industry by providing essential materials that are durable, lightweight, and resistant to extreme temperatures and pressure. It is used for manufacturing critical components such as engine parts, landing gear, turbine blades, and structural components, ensuring the reliability and safety of aircraft. Additionally, special steel's high strength-to-weight ratio allows for improved fuel efficiency, reducing operational costs and environmental impact.

Send your message to us

Deformed Bars BS4449 B460B for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords