Deformed Steel Bar BS4449 GR.460B GR.B500B

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Steel rebar

Price: FOB $475-535/MT

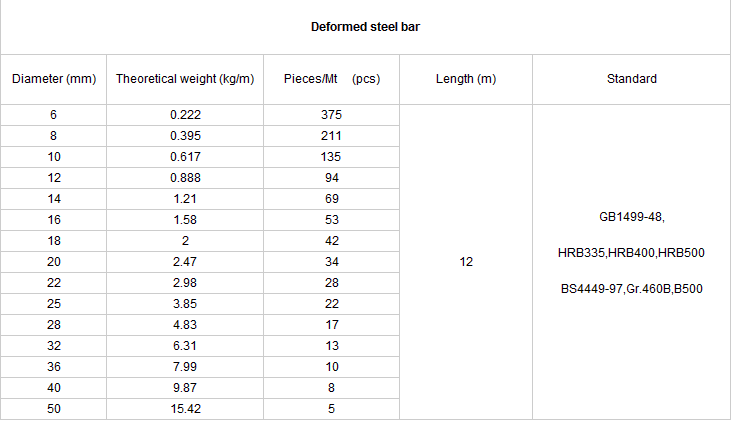

Size:6-50mm

Moq: 300tons of each size

Material: BS4449 GR460, ASTM A615, HRB400, HRB500

Steel rebar/deformed steel bar/reinforced steel bar

1.Standard: ASTM,BS,DIN,JIS,BS 4449 GR460B-1997. ASTM A615/706 GR 40/60, GB(HRB400,500)

2.Grade:HRB35, HRB400, HRB500,

3.Diameter:6-50mm

4.Length:6-12m and in coils

5.Place of Origin: Tangshan, China (Mainland)

6.Brand Name: CNBM

7.Material: cabon steel

8.Color: black

9.Packing: bundles or as per the buyers' requirement.

10. Minimum Order Quantity: 500 MTS as per size.

11. Payment terms: TT or LC at sight.

12. Delivery time: within 25-30 days after down payment or L/C received.

13. Application: Construction,Bridge Building, Road Building

- Q: Can steel rebars be used in cold weather concreting?

- Yes, steel rebars can be used in cold weather concreting. However, certain precautions need to be taken to ensure that the concrete sets properly and the rebars do not experience any issues due to the cold temperatures. These precautions may include using additives in the concrete mix to improve its cold weather performance, providing proper insulation and heating to protect the concrete during curing, and implementing proper construction practices to prevent freezing and thawing cycles that can damage the rebars.

- Q: What are the main uses of threaded steel?

- The difference between round bar and round bar is that the surface has longitudinal ribs and transverse ribs, usually with two longitudinal ribs and transverse ribs uniformly distributed along the length direction.

- Q: How are steel rebars protected from corrosion?

- Steel rebars are protected from corrosion through various methods such as epoxy coating, hot-dip galvanizing, and cathodic protection. These techniques create a barrier between the rebar and the corrosive environment, preventing the steel from coming into contact with moisture and oxygen, which are the main causes of corrosion.

- Q: What is the recommended diameter of steel rebars for foundation reinforcement?

- The recommended diameter of steel rebars for foundation reinforcement typically ranges from 12mm to 32mm, depending on the specific requirements and load-bearing capacity of the foundation.

- Q: How do steel rebars contribute to the crack-resistance of concrete?

- Crucial in improving the crack-resistance of concrete structures are steel rebars, also known as reinforcement bars. These rebars serve as a reinforcement system when embedded within concrete, aiding in the distribution and resistance of tensile forces. This is particularly important due to the relatively low tensile strength of concrete, despite its high compressive strength. The absorption of tensile stresses is the primary means by which rebars contribute to crack-resistance. Without rebars, these stresses would lead to the development of cracks in the concrete. By bearing the tension forces as the load is applied to the structure, the rebars prevent excessive tensile stress and subsequent cracking. This is especially crucial in areas subjected to bending or flexing forces. Additionally, the bond strength between the rebars and the surrounding concrete plays a role in crack-resistance. The presence of rebars improves this bond, preventing the separation or debonding of the concrete under stress. This ensures effective load transfer between the rebars and the concrete, further reducing the likelihood of cracks. Furthermore, steel rebars aid in controlling crack widths in concrete. Acting as a restraint when tensile forces are applied, the rebars limit the width of any cracks that may form. This prevents the cracks from widening and becoming more severe, preserving the overall integrity and durability of the structure. To summarize, steel rebars play a significant role in enhancing the crack-resistance of concrete by absorbing tensile stresses, improving bond strength, and controlling crack widths. Their presence within the concrete structure aids in the distribution and resistance of forces, preventing the formation of cracks and ensuring the longevity and safety of the construction.

- Q: What are the different methods of protecting steel rebars from fire?

- There are several methods of protecting steel rebars from fire. One common approach is to apply a coating of fire-resistant material, such as intumescent paint or epoxy-based fireproofing, directly onto the rebar surface. These coatings expand and form a protective layer when exposed to high temperatures, slowing down the transfer of heat to the steel and delaying its structural weakening. Another method involves encasing the rebars in fire-resistant materials, such as concrete or gypsum board, creating a barrier between the steel and the fire. Additionally, fireproofing sprays and wraps can be used to provide temporary protection during construction or renovation projects. Each method has its own advantages and suitability depending on the specific application and fire safety requirements.

- Q: Can steel rebars be used in railway construction?

- Yes, steel rebars can be used in railway construction. Steel rebars are commonly used as reinforcement in concrete structures, including railway bridges, tunnels, and track foundations, to enhance their strength and durability.

- Q: How do steel rebars affect the thermal conductivity of concrete?

- Steel rebars have a significant impact on the thermal conductivity of concrete. Due to their high thermal conductivity, steel rebars act as conductive pathways, allowing heat to easily transfer through the concrete. This results in an increased overall thermal conductivity of the concrete structure.

- Q: What are the different methods of connecting steel rebars together?

- There are several different methods of connecting steel rebars together, depending on the specific requirements of the construction project. Some of the most common methods include: 1. Lap Splicing: This involves overlapping two rebars and then securing them together using steel wire or steel bars. It is a simple and cost-effective method but requires a longer length of rebars. 2. Mechanical Splicing: In this method, a mechanical coupler is used to connect two rebars together. The coupler is usually a sleeve or a collar that is attached to the ends of the rebars, providing a strong and reliable connection. Mechanical splicing is faster and more efficient than lap splicing, and it also allows for flexibility in positioning the rebars. 3. Welding: Welding is another method of connecting steel rebars, where the ends of the rebars are heated and fused together using an electric arc. This creates a strong and permanent connection. However, welding requires skilled labor and can be time-consuming and costly. 4. Threaded Couplers: Threaded couplers are similar to mechanical splicing, but instead of using a sleeve or collar, the rebars are threaded at the ends and then connected using a threaded coupler. This method provides a strong and reliable connection and is often used in larger construction projects. 5. Grout Sleeve Splicing: This method involves placing a grout-filled sleeve between two rebars to create a connection. The grout provides additional strength and stability to the joint. Grout sleeve splicing is commonly used in seismic zones or areas where high strength and ductility are required. 6. Reinforcing Bar Couplers (RBC): RBC is a proprietary method of connecting rebars, where a threaded sleeve is used to connect the rebars. The sleeve is filled with epoxy resin to create a strong bond. RBC offers high load capacity, ease of installation, and resistance to corrosion. It is important to consult with structural engineers and follow building codes and regulations to determine the most appropriate method of connecting steel rebars for a specific construction project.

- Q: What is the effect of impurities on the corrosion resistance of steel rebars?

- Impurities can have a significant effect on the corrosion resistance of steel rebars. Steel rebars are primarily composed of iron and carbon, but impurities such as sulfur, phosphorus, and silicon can be present in varying amounts. Sulfur, for example, is a common impurity found in steel. It can react with water and oxygen to form sulfuric acid, which accelerates the corrosion process. This acid attack can cause the rebars to deteriorate faster, reducing their overall strength and durability. Phosphorus is another impurity that can negatively impact the corrosion resistance of steel rebars. It can promote the formation of localized corrosion sites, known as pitting, which can lead to the development of rust and eventual structural damage. Silicon, although generally considered a beneficial element in steel production, can also have an adverse effect when present in excessive amounts. Higher silicon levels in rebars can lead to the formation of a protective oxide layer, but this layer can sometimes be porous, allowing the penetration of corrosive agents and resulting in corrosion. Overall, the presence of impurities in steel rebars can compromise their corrosion resistance. It is crucial to ensure that the steel used in construction meets the specified standards and contains minimal impurities. Additionally, proper maintenance and regular inspection of rebars are essential to identify and address any potential corrosion issues before they lead to significant damage or structural failures.

Send your message to us

Deformed Steel Bar BS4449 GR.460B GR.B500B

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords