Copper Conductor PVC Control Cable 300/500V,450/750V

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

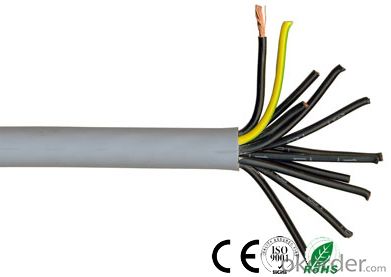

Copper conductor PVC Control Cable 300/500V,450/750V

1.APPLICATION

This kind of cable is Used as power and connecting cables in mechanical engineering for tooling machinery, control unit, production lines, transportation equipment, conveyor and assembly lines as well as in plant construction. BDK control cable has the advantages of high mechanical strength, good ambient stree resistance, good electrical properties and anti-chemical corrosion.

2.PRODUCT DESCRIPTION

Voltage rating: 300/500V, 450/750V

Standard applied: IEC60227, BS6500, GB/T9330

Max. working temp.: 70°C

Conductor: Class 1/2 annealed bare copper solid or strands or Class 5 fine annealed copper wire

Insulation & outer sheath: PVC

Armoure or shield (optional): SWA or STA or copper braided screen or tinned copper wire scree

Cores: 2C~61C

Cross section area: 0.75 ~ 10 sqmm

Sheath color: Black or as per requirement

Bending radius: Not less than 6 times of the cable's OD (unarmoured type and flexible shielded type); Not less than 12 times of the Cable's OD (armoured or copper shielded type)

Ambient temp. for laying the cable: Not less than 0°C; if below 0°C, cables should be preheated

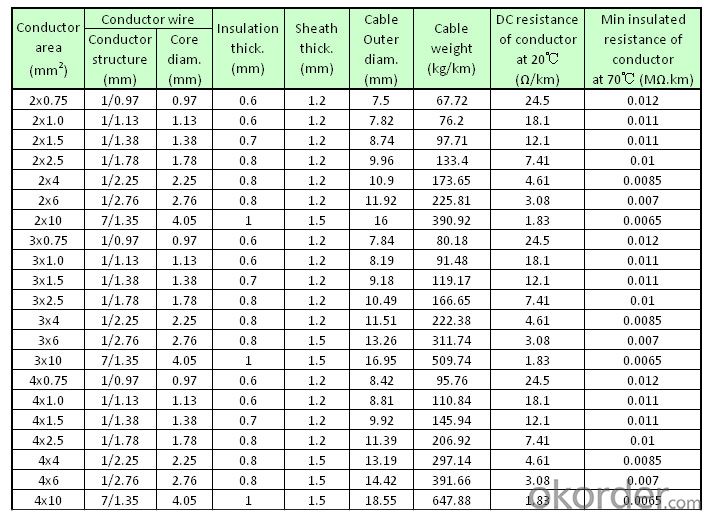

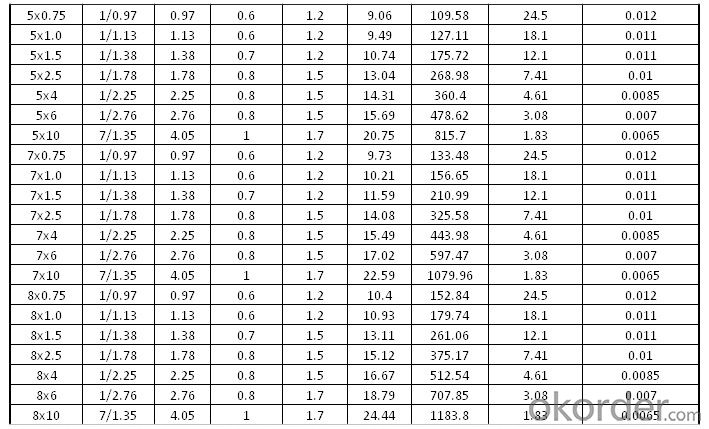

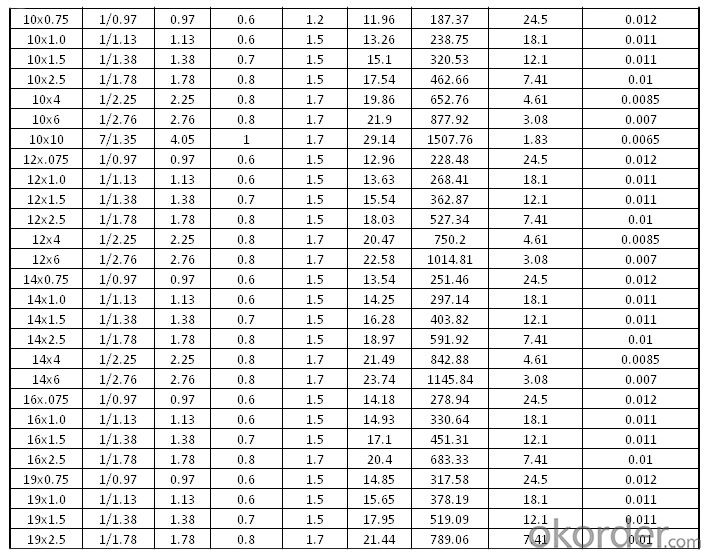

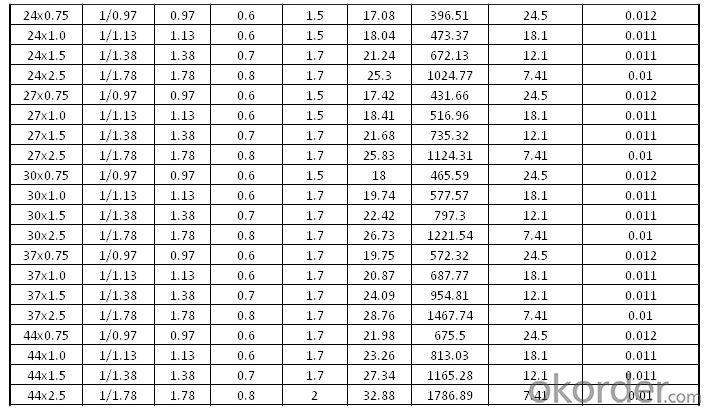

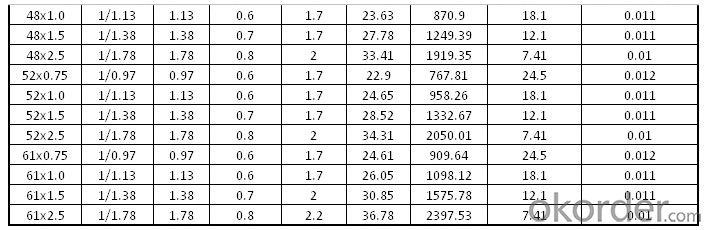

3.PARAMETER SHEETS

4. MANUFACTURING PROCEDURE

1. Copper wire drawing and annealing

2. Copper wire stranding

3. Outer sheath extruding and labeling

4. Spooling

5.Production facility

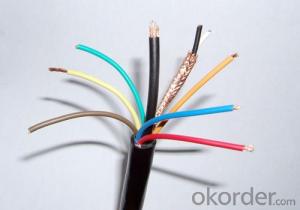

- Q: Wire yellow and green, respectively, that line of fire or zero line

- Third, in the cable trench, tunnel, when both sides of the cable bracket, 1000 volts below the power cable and control cables should be as much as 1000 volts and above the power cables were laid on different stents Fourth, the height of the cable tunnel is generally 19 meters; difficulties, in the local area may be appropriate to reduce the length of the cable bracket in the cable trench should not be greater than 350 mm; in the tunnel should not be greater than 500 mm cable in the cable trench, tunnel laying when the net distance, should not be less than the specified value Cable trenches and wire tunnels should be waterproof; the slope of the bottom drains should not be less than O 5%, and should be set water puddle; water can be collected by the puddle pump, when the conditions, the water can be directly discharged into the sewer

- Q: I am experiencing a problem with electrical wiring. I was trying to change a lightswitch to a duplex lightswitch/outlet. I could only get the outlet to work, not the lightswitch part. So I deceided to switch back to my original lightswitch (that originally worked just fine) because I would have to wait for someone who knows more to help me with the duplex. Now the lightswitch doesn't work either. What could have happend to cause this and how do I fix this?

- Did i get you right , that what you needed is a light switch and an extra outlet? the power line for a light switch, one passing thru the switch then connected to the light, while the other, live one is connected directly to your light or receptacles, when you switch the light the line that pass thru you switch is powered giving you a positive and negative power. to light your lamp. Now when you installed an additional outlet, you must connect the two negative and positive wire to your outlet. See to it that the line connected to your receptacles is not altered but connected to one terminal of your outlet say as the positive line,while the other line the negative line, connected to your outlet should extend thru your switch then from switch this line shall be connected to your receptacle to complete the connection. I presumed that you know how to connect the wire to your switch. This is only a single live wire, cut off into two, one connected to he upper terminal of your switch and the one one connected to lower terminal then this line is connected to the terminal of your receptacle to complete the cycle. Check that even if your light is off, your outlet must be energised if it is not, then review your connection The failure of your light switch might be due to loose connection or parts of it isn't working anymore that you need to change it to new one.

- Q: I live in a home that is 50 plus years old. All of the electrical outlets in the home are the out dated 2 prong plug ins. Are there any safety issues associate with replacing the outdated 2 prong outlet with a 3 prong outlet to power a metal halide high bay light fixture with a 400 watt ballast? The wiring in the wall is also outdated and does NOT have the up to date 3 wire electrical supply.

- No, because the fixture has a transformer, and if the transformer fails it can energize the metal parts of the fixture. The purpose of a ground is to provide a current path to ground from the chassis to operate the overcurrent device if the chassis becomes energized. Without a ground wire the current may find another current that may ignite combustibles.

- Q: I would like to wire two wall sconces on either side of my fireplace. I was planning on continuing the electrical circuit from a wall outlet located near the fireplace and including an inline switch. The outlet is on the left side of the fireplace so I was planning on running the wire 6 feet strait up from the outlet, over three feet, installing a new electrical box and mounting the sconce. The question I have is, how can I run the wire to the other sconce on the right side of the fireplace. Can I run the wire in the wall in front of the fireplace? Also is there any electrical codes that require switches to be a certain height off the floor? I live in southern California.

- The best way would be to run the wires right up the wall from the first box, into the attic/ceiling, then over and down for the second box. Switches are generally about 48 to center of the box.

- Q: I am removing a buried junction box. The feed wire is still present but I don't have the new junction box ready. Can I put a wire nut on and electrical tape until I get my supplies?

- its fine just don't put the hot and neutral wire together also make sure that the junction box is accessible if it not then its a code violation and if you sell the house you can get sued for it.

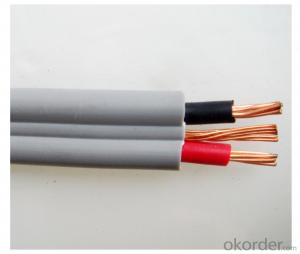

- Q: 3000W electric water heater with more thick power cord

- Commonly used totem cabinet line shape has a positive line, reverse line and waterfall modeling three, you have mastered it? Let's take a look at it

- Q: I am trying to completely remove a dishwasher. I don't want to replace it, just remove it and convert the space to shelf space. The electrical is hardwired to the dishwasher. I already have the breaker off and it can stay off indefinitely. How do I cap the wire ends so it will be safe if someone accidentally turns the breaker back on and those go live? Should I just use wire nuts? Thanks

- Capping Electrical Wires

- Q: how do i wire a 3 prong range (red,white, and i can't tell the other color it just has a block where all 3 wires meet and a washer type sticking out to screw to oven) and i want to wire it to a 4 prong 220v outlet right behind it. i got a 220v plug and 6-4 slow cord to use with 4 wires. red,black, white, green. which wire goes where? i have a good idea but double checking with u guys just to be safe. i was told nuetral wire is sometimes not needed?? plz help. any help +++++

- red positive .black neg .green earth. not sure about white turn of from mains and check connection wires at back of plate it can be screwed out .that will let you be safe and sure.never seen white on any wiring system.always red black and green i have seen and wired my own oven with those three only/.

- Q: I want install 4 outlets 120/20A next each other in separate circuit breakers.The distance between panel and outlets around 150 feet. and run conduit 3/4. To save cost. How many or a minimum #12 wires can I use. I have 4 hot wires dedicated for each circuit breakers. And for neutral wires can i use 1or 2 white to all outlets and one green for all 4 outlets or I have to use sepreate neutral/w to each outlet from the panel.

- if you use twin pole circuits (230 split outlets) then you can share a neutral wire in the circuit 4 outlets 6 wires. (use 2 red 2 black 2 white) If you use two circuits of the same leg from the panel then you cannot share a neutral. Check the codes in your country, Some places have code requiring a separate neutral for each outlet in case a later modification is done stupidly.

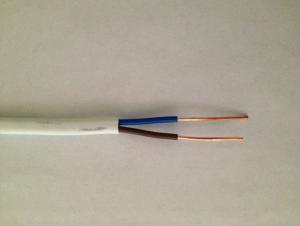

- Q: I know what the hot wire and ground wire are but why do you need a neutral wire? The hot wire is black and the ground is green right? So neutral is white? My bigger question though is why do you need a neutral wire--what is its purpose? Thank you!

- The neutral is to carry all the return current from the hot wire, while the ground is only for safety. In the US, the National Electrical Code (National Fire Protection Agency document 70) is the law of the land and it requires the neutral to be grounded at the service entrance and nowhere else. There are also electrical reasons to do it that way - if you connected the return side of everything in the house to ground instead of to return wires that returned all the way to the service entrance, the finite resistance of the ground would cause lights to dim whenever you turned anything in the house on.

Send your message to us

Copper Conductor PVC Control Cable 300/500V,450/750V

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches