Construction Galvanized Steel Kwikstage Scaffolding System with High Quality CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Construction Galvanized Steel Kwikstage Scaffolding System with High Quality

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Brand Name:

Surface:

Material.:

Thickness:

Descriptions of Construction Galvanized Steel Kwikstage Scaffolding System with High Quality

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

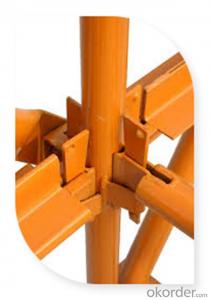

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Construction Galvanized Steel Kwikstage Scaffolding System with High Quality

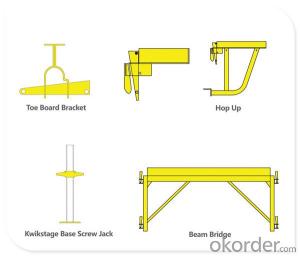

Kwikstage Products: Standard; Ledgers; Transom; Steel Plank; Hop Ups; Diagonal Braces; Tie Bars; Toe board Brackets; End Toe Board Brackets; Double C Clip; External Cup Standard

Props and Formwork: Formwork Prop; Formwork Jacks ; Shoring Jacks

Other Accessories: Ladder Beams; Aluminium Stair ; Base Jack; Swivel Jack ; Steel Pallet; Steel Mesh Pallet.A)Kwikstage Standard

Length: 3.0m;2.5m;2.0m;1.5m;1.0m;0.5m Thickness: 4mm Surface: Painted or Hot Dipped Galvanized Certificate: AS / NZS 1576.3-1995 B) Kwikstage Ledgers

Surface painted or hot dipped galvanized Thickness 3.2mm; 3mm Length 2.4m; 1.8m; 1.2m; 0.7m Certificate AS / NZS 1576.3-1995 C) Kwikstage Transom

Surface painted or hot dipped galvanized Thickness 5mm Length 2.4m;1.8m;1.2m;1.0m;0.7m D)Kwikstage Scaffolding Steel Board / Steel Plank

Length 2.4m ; 1.8m; 1.2m; 0.7m Thickness 1.8mm galv.iron sheet Certificate AS 1577-1993 FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Exterior wall scaffold construction plan?

- Big bar:The large cross bar is arranged above the cross bar, and the inner side of the vertical rod is fastened with a right angle fastener and a vertical rod, and the length of the utility model is not less than 6m of the span of the 3m. The large cross bar is connected with a butt fastener, and the joint is arranged in a staggered way, not in the same time and in the same distance. The horizontal distance of adjacent joints shall not be less than 50cm. The distance from the joint to the riser is not more than 50cm

- Q: How long is the service life of disc scaffolding?

- In the service life of the product if the corrosion and deformation can not be put into the construction of the building.

- Q: Every time someone in medieval times was murdered by the beheading a new scaffold was built for the next prisoner.

- Well that's not entirely true; they didn't ALWAYS built a new scaffold. Probably movies let you think so but that was not the case.

- Q: Fastener type steel pipe scaffold composed of two components? What are the roles?

- 2.1 divide the material according to the bar1) single specification steel pipe scaffold. It only uses a steel pipe specifications, such as steel tubular scaffolding, welded steel pipe using only 48 * 3.5.2) a variety of specifications of steel pipe scaffolding. The utility model is composed of two or more steel pipes of different specifications, such as a door type scaffold.3) steel tubular scaffolding. As to the steel pipe, and combined with other type of steel pieces composed of scaffolding, such as the channel has a base in the backwater or scaffolding, connecting steel scaffolding and so on.

- Q: so yeah as it says above^should i just wait till it no longer hurts, or do you have to wait a certain amount of time...

- Industrial piercings take 9-12 months to heal completely and you never want to remove an unhealed piercing unless the jewelry is causing problems and at that point it should be done by a professional in a sterile environment. Taking the jewelry out before it is healed could cause it to close up, become infected or irritated, and can cause hypertrophic scarring (scar tissue) to form on your piercing. I took my industrial out after having it for 3 months. It was out for less than a minute and when I went to put it back in it went through the first hole easily but wouldn't go through the top hole no matter how hard I pushed. It immediately started bleeding and hurtling like crazy. Awesome. Waste of time, pain, and money. So, you might get lucky and just have it get a little irritated or prolong the healing time by changing it early. But you could also end up like me or worse, with any infected piercing. Why risk it?

- Q: ...and I'm not really sure what to expect. I know that everyones healing time and pain tolerence is different but just some personal storys would be nice. And before you say it I am aware that there are risks as there are risks with any piercing. so I'm 17 from London and wondering:How old do you have to be to get it done?Does anyone know a reputable place i can get it done?How much will it be?any experiences to share?

- I haven't had this piercing but i was thinking of getting one i do have an eyebrow ring and seven earrings in each ear and i use to have a tongue ring, your piercing cartilidge so it is going to sting shouldnt be too bad though for me my most painful piercing was my fourth earring hurt after that it wasnt too bad my seventh was a breeze i knew how to take care of it so that it would heal fast and not get infected. you have to daily sometimes twice a day clean it otherwise it gets infected and its been my exerpience that they get infected easy. the healing time for when you pierce cartilidge is twice that of when you pierce your lobe so about 8-12 weeks give or take as far as i know you have to be 18 to get one if your in the US (or 17 with parental consent) not sure what the age would be over in London as for reputable place most tatto parlors do piercings look for a clean place that sterlizes everything very important (again going on US standards) as for the cost not sure was 10 dollars for ear piercing at wal mart but for this kind of ear piercing i would guess 20-30 dollars cause its at leadt 50 for a eyebrow or tongue ring i know that. i hope this helps good luck

- Q: Scaffolding Vertical Standard, Length: 3000mm, Part Number AS1001

- Please okorder Type ‘Aluminum Scaffolding+supplier+your location’ into its ‘Search’ panel, and click on ‘Enter’. Several pages of site listings giving details and links of suppliers who offer Aluminum Scaffoldings in, or near, your locality will be presented to you. Contact them, one by one, and then choose the supplier who suits your specific needs best. Happy hunting !

- Q: This is an answer to irreducible complexity. Are there any examples that we see in animals or organs? or on the cellular level? Are vestigial organs a form of quot;scaffoldingquot; that are in the process of being removed?

- The classic demonstration was in the E. coli long term experiment. A strain gained the ability to metabolize citric acid after 31,500 generations. Culturing preserved strains from 15,000 and 20,000 generations showed that there was an event that occurred in between that enabled the later conversion to citrate metabolism.

- Q: What could you do with 100,000 jumbo cotton balls, 50 gallons of honey, and three story scaffolding?

- ummmm oh i got a good one i hope and that is to build the world's largest bee's hive. plus they make more honey and i would have tons of money, pretty sweet isn't it.

- Q: improper design of formwork and scaffolding, not adequate braces and supports, improper handling, corrosion of material is several factor of formwork and scaffolding failure. it is estimated that more than 3000 accidents involving falls from scaffolds and 30 fatalities

- Improper assembly seems to be a big one. Workers often neglect to install the internal diagonal from upper corner to opposite lower corner when it comes to scaffolding. Formwork usually fails by inadequate bracing at the bottom as hydrostatic pressure builds. This can be mitigated to some extent by allowing the concrete to set up a bit before pouring the next layer. For earth formwork, you have to be real careful about expansive clay becoming saturated and overwhelming the bracing as it expands.

Send your message to us

Construction Galvanized Steel Kwikstage Scaffolding System with High Quality CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords