Colored Corrugate GI Coated Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colored Corrugate GI Coated Roofing Sheet

Description for Colored Corrugate GI Coated Roofing Sheet

PPGI Coil | Width | Thickness | Zinc Thickness | Face | Back |

600mm-1250mm | 0.12mm-0.8mm | 30-120g | 15-25u | 5-13u | |

Color | Raul color card , or your model color | ||||

Coil Weight | 3Ton--5Ton . | ||||

Packing | standard export packing . | ||||

Payment Terms | T/T, L/C , | ||||

Trade Terms | FOB , CNF/CFR, CIF | ||||

Loading Port | Qingdao /Tianjin ,China | ||||

Delivery Time | 25days base on order quantity | ||||

Main Structure for Colored Corrugate GI Coated Roofing Sheet:

Thickness :0.18mm-0.8mm

Application: for the construction industrial :

Building construction.

portable roofing.

side plate .

Steel grade: prepainted coil .

galvanized coil .

FAQ

Why should you choose us :

Stable quality ----continous casting hot rolled production techenic, strictly quality control system.

Lower price -------Not the cheapest but the lowest price at the same quality .

Good service -----Satisfactory service within 24hours.

Delivery time ------15-25days for the mass production .

Discount---------------discount base on monthly large quantity purchase in long term.

Advantages of Colored Corrugate GI Coated Roofing Sheet :

Rich experiences------------- more than 13 years experience in steel industry.

Alibaba Golden Supplier-----factory recognized ISO certificates etc.

Professional sales team------International trade teams for your service .

7/24 service for you------------all questions will be deal with within 24 hours .

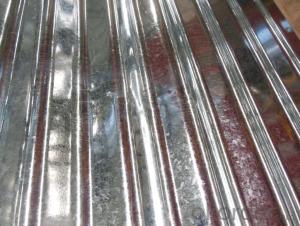

Picture:

- Q: Are steel sheets resistant to chemical spills?

- Yes, steel sheets are generally resistant to chemical spills. Steel is known for its durability and ability to withstand various chemical substances without corroding or reacting. However, the resistance may vary depending on the specific type of steel and the type and concentration of the chemical involved. It is always recommended to assess the compatibility of the steel with the specific chemical before making any conclusions about its resistance.

- Q: Do steel sheets require any special storage or handling?

- Yes, steel sheets require special storage and handling to ensure their integrity and avoid any damage. They should be stored in a clean, dry, and well-ventilated area to prevent corrosion. Additionally, they should be stacked in a way that prevents distortion or bending. When handling steel sheets, it is important to use proper lifting equipment and techniques to prevent accidents and maintain the quality of the sheets.

- Q: What is the average lead time for ordering steel sheets?

- The average lead time for ordering steel sheets varies depending on the supplier and the specific circumstances, but it typically ranges from 1 to 4 weeks.

- Q: Can steel sheets be used for automotive suspension components?

- Yes, steel sheets can be used for automotive suspension components. Steel offers high strength and durability, making it a suitable material for the suspension system, which withstands significant loads and impacts. Steel sheets can be shaped and formed into various suspension components such as control arms, springs, and stabilizer bars, providing the necessary structural support and stability required for a vehicle's suspension system.

- Q: How do steel sheets handle weathering?

- Steel sheets have been designed to effectively handle weathering. Typically, they are coated with a protective layer, such as zinc or a combination of zinc and aluminum, which creates a barrier against moisture and other environmental elements. This coating, known as galvanization, prevents the steel from corroding or rusting when exposed to rain, snow, and other forms of precipitation. Aside from the protective coating, various chemical processes are used to enhance the steel sheets' resistance to weathering. These processes may involve applying primers, paints, or sealants that further shield the steel from moisture, UV radiation, and extreme temperature fluctuations. Furthermore, the composition of steel itself contributes to its ability to withstand weathering. Steel is primarily comprised of iron, carbon, and other elements, forming an alloy that provides inherent strength and durability. This structural integrity enables steel sheets to resist deformation, cracking, or warping caused by weather-related stresses. However, it is important to acknowledge that even the most well-protected steel sheets may gradually experience some degree of weathering over time. Harsh environmental conditions can gradually degrade the protective coating, resulting in the formation of small areas of rust or corrosion. Regular maintenance, such as cleaning, inspecting, and reapplying protective coatings, can help extend the lifespan of steel sheets and preserve their resistance to weathering.

- Q: Are the steel sheets resistant to impact or bending?

- Yes, steel sheets are generally resistant to both impact and bending. Steel is known for its high strength and durability, making it less likely to be affected by external forces such as impacts or bending. This is due to the material's ability to absorb and distribute the energy applied to it, resulting in minimal deformation or damage. However, the specific resistance to impact and bending may vary depending on the thickness, type of steel, and any additional treatments or coatings applied to the sheets.

- Q: How do steel sheets perform in terms of electrical resistance?

- Steel sheets are generally poor conductors of electricity due to their high electrical resistance.

- Q: Can steel sheets be used for outdoor applications?

- Yes, steel sheets can be used for outdoor applications. Steel is known for its durability, strength, and resistance to corrosion, making it an ideal material for various outdoor uses such as roofing, siding, fences, and outdoor structures.

- Q: What is the cost of steel sheets compared to other materials?

- The cost of steel sheets typically varies depending on factors such as size, thickness, and specific type of steel. However, in general, steel sheets tend to be more affordable compared to other materials such as aluminum or titanium.

- Q: Are the steel sheets suitable for solar panel mounting?

- Indeed, steel sheets prove to be a fitting choice for the mounting of solar panels. Possessing formidable strength and durability, steel emerges as a material capable of furnishing a steadfast and protected groundwork for these panels. It boasts the requisite robustness to bear the weight of the panels while enduring diverse weather conditions. Moreover, steel sheets can be readily fabricated and tailored to meet the precise demands of the solar panel installation. In essence, the utilization of steel sheets for solar panel mounting guarantees an unwavering and enduring foundation for the panels.

Send your message to us

Colored Corrugate GI Coated Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords