Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures:

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

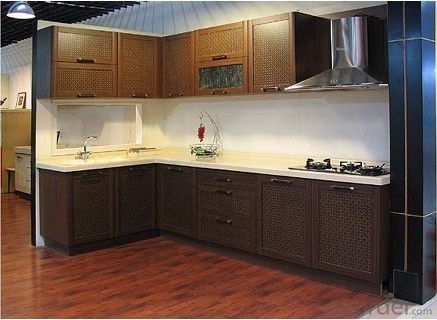

3.Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures Images

4.Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

- Q: What are the different surface treatments available for steel sheets to enhance their appearance?

- There are several surface treatments available for steel sheets to enhance their appearance. Some common methods include polishing, brushing, and painting. Polishing involves using abrasive materials to create a smooth and shiny surface. Brushing uses wire brushes to create a textured and matte finish. Painting involves applying a layer of paint to add color and protection to the steel sheet. Additionally, there are also options like galvanizing, which involves coating the steel with a layer of zinc to prevent corrosion and give it a metallic look.

- Q: Can steel sheets be used for electrical motors?

- Indeed, electrical motors can utilize steel sheets. Due to its magnetic properties, steel is frequently employed in the construction of these motors. Specifically, the sheets of steel are typically utilized to form the motor's core, which is responsible for generating the essential magnetic field. With its high magnetic permeability, steel can effortlessly conduct and direct magnetic flux, rendering it an optimal material for this purpose. Moreover, steel is durable and capable of withstanding the elevated temperatures and mechanical pressures that electrical motors may encounter while in operation. Consequently, steel sheets are frequently selected as a dependable and economical choice for constructing electrical motors.

- Q: How do steel sheets handle extreme weather conditions?

- Steel sheets are highly resistant to extreme weather conditions. They are able to withstand high winds, heavy rain, snow, and even hail. Their strength and durability make them ideal for withstanding harsh weather elements, ensuring that they can protect buildings and structures effectively. Additionally, steel sheets are non-combustible, making them resistant to fire, which is another advantage in extreme weather situations.

- Q: What is the maximum temperature steel sheets can withstand?

- The maximum temperature steel sheets can withstand varies depending on the grade and composition of the steel. However, most common grades of steel can withstand temperatures up to around 600-650 degrees Celsius (1112-1202 degrees Fahrenheit) without significant loss of strength.

- Q: Are the steel sheets suitable for architectural cladding?

- Yes, steel sheets are suitable for architectural cladding due to their durability, strength, and versatility in design. Steel sheets can be fabricated into various shapes and sizes, offering flexibility for architectural purposes. Additionally, they provide excellent weather resistance and require minimal maintenance, making them an ideal choice for cladding applications.

- Q: Can steel sheets be used in the aerospace industry?

- Yes, steel sheets can be used in the aerospace industry.

- Q: Can the steel sheets be used for decorative purposes?

- Certainly, decorative purposes can be fulfilled by steel sheets. Customization and shaping of steel sheets into an array of designs, patterns, and sizes enable their suitability for diverse decorative applications. They are ideal for crafting distinctive and contemporary architectural elements like ornamental facades, decorative wall panels, or intricate metal screens. Moreover, steel sheets find utility in decorative furniture, art installations, and sculptures. Their popularity stems from their versatility, durability, and sleek appearance, which effortlessly infuse spaces with elegance and sophistication, both indoors and outdoors.

- Q: What is the lifespan of a steel sheet?

- The lifespan of a steel sheet can vary depending on several factors such as the quality of the steel, the environment it is exposed to, and the maintenance it receives. However, on average, a properly maintained steel sheet can last anywhere from 20 to 30 years or even longer.

- Q: How are steel sheets protected during transportation by air?

- Steel sheets are protected during transportation by air through various measures such as packaging them in protective covers, using cushioning materials like foam or bubble wrap, securing them with straps or bands to prevent movement, and placing them in sturdy crates or pallets to minimize the risk of damage. Additionally, some steel sheets may undergo corrosion-resistant coatings or be stored in climate-controlled containers to protect them from moisture or extreme temperature changes during transit.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. Steel is a strong and durable material that can provide a stable and secure base for solar panels. It has the necessary strength to support the weight of the panels and withstand various weather conditions. Additionally, steel sheets can be easily fabricated and customized to fit the specific requirements of the solar panel installation. Overall, using steel sheets for solar panel mounting can ensure a reliable and long-lasting foundation for the panels.

Send your message to us

Print Prepainted Galvanized Steel Coil Wooden Pattern for Furnitures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords