Print Prepainted Galvanized Steel Coil Wooden Pattern for Army

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Print Prepainted Galvanized Steel Coil Wooden Pattern for Army:

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Print Prepainted Galvanized Steel Coil Wooden Pattern for Army:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

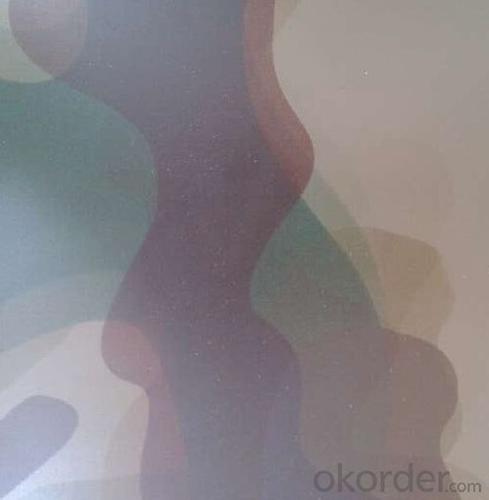

3.Print Prepainted Galvanized Steel Coil Wooden Pattern for Army Images

4.Print Prepainted Galvanized Steel Coil Wooden Pattern for Army Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Print Prepainted Galvanized Steel Coil Wooden Pattern for Army

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your moq

Normally our moq is 25mt per size ,but it is up to different size.

- Q: What safety precautions should be taken when handling steel sheets?

- When handling steel sheets, it is important to take the following safety precautions: 1. Use appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against cuts, abrasions, and possible falling objects. 2. Ensure proper body mechanics and lifting techniques when handling heavy steel sheets to prevent back strain or injuries. Consider using mechanical aids like cranes or forklifts when necessary. 3. Inspect the sheets for sharp edges, burrs, or other defects that could cause cuts or punctures. If any defects are found, they should be addressed or the sheet should be replaced. 4. Store the steel sheets in a stable and secure manner, ensuring they are properly stacked and secured to prevent them from falling or shifting. 5. Use caution when transporting the sheets, ensuring they are securely fastened and properly balanced on carts or trucks to avoid accidents or injuries. 6. Avoid working alone when handling large or heavy steel sheets. Having a colleague nearby can provide assistance and ensure prompt response in case of emergencies. 7. Maintain a clean and organized work area to minimize the risk of tripping or slipping on debris or loose materials. 8. Follow proper material handling procedures and techniques to prevent accidental drops or improper placement of the steel sheets. 9. Take precautions against fire hazards by keeping flammable materials away from the steel sheets and having appropriate fire extinguishing equipment readily available. 10. Provide training and instruction to all personnel involved in handling steel sheets to ensure they are aware of the hazards and safety procedures associated with this task.

- Q: What is the average thermal expansion coefficient of steel sheets?

- The specific type of steel and its composition determine the average thermal expansion coefficient of steel sheets. Nonetheless, a widely accepted approximation for the thermal expansion coefficient of steel sheets is approximately 12 x 10^-6 per degree Celsius (12 parts per million per degree Celsius). It is pertinent to mention that this approximation may slightly deviate depending on the grade and composition of the steel utilized.

- Q: How is the normalized steel plate produced?

- Normalizing, also known as normalizing, is to heat the workpiece between 727 and 912 degrees Celsius. 40~60min, after a period of heat preservation, is removed from the furnace and cooled by air or by spray, spray, or blow cooling. Its purpose is to make grain refinement and carbide distribution homogenization, to remove the internal stress of materials.

- Q: Can steel sheets be welded or joined together?

- Yes, steel sheets can be welded or joined together. Welding is a common method used to join steel sheets together. It involves melting the edges of the sheets and then allowing them to cool and solidify, creating a strong bond between the two sheets. Welding is an effective way to join steel sheets as it provides a durable and permanent connection that can withstand high levels of stress and load. Additionally, other methods such as riveting, bolting, and adhesive bonding can also be used to join steel sheets together depending on the specific application and requirements.

- Q: What are the different types of steel coatings for sheets?

- Some of the different types of steel coatings for sheets include galvanized steel, zinc-coated steel, tin-plated steel, and stainless steel.

- Q: How are steel sheets packaged for shipping?

- Steel sheets are typically packaged for shipping by being stacked on wooden pallets and secured with steel or plastic strapping. Additionally, they may be further protected by being wrapped in plastic or covered with a cardboard or wooden crate for added stability and protection during transportation.

- Q: Are steel sheets suitable for manufacturing HVAC grilles?

- Yes, steel sheets are suitable for manufacturing HVAC grilles. Steel sheets offer durability, strength, and corrosion resistance, making them an ideal material for HVAC grilles that need to withstand various environmental conditions. Additionally, steel sheets can be easily shaped and customized to meet specific design requirements, ensuring proper airflow and efficient functioning of the HVAC system.

- Q: Can steel sheets be used for elevator doors?

- Yes, steel sheets can be used for elevator doors. Steel is a commonly used material for elevator doors due to its strength, durability, and fire-resistant properties.

- Q: What is the yield strength of steel sheets?

- The yield strength of steel sheets can vary depending on the specific grade and thickness, but typically ranges between 250 and 400 megapascals (MPa).

- Q: Is galvanized steel plate fire-resistant?

- Galvanized steel is mainly antiseptic, and he has no fire protection

Send your message to us

Print Prepainted Galvanized Steel Coil Wooden Pattern for Army

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords