Prepainted Galvanized Steel Sheets in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

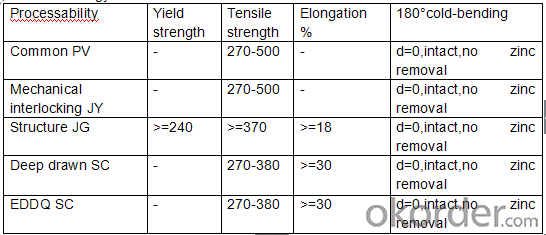

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used for roofing?

- Yes, steel sheets can be used for roofing. Steel is a durable and long-lasting material that provides excellent protection against weather elements, making it a popular choice for roofing applications.

- Q: What are the different surface treatments for steel sheets?

- There are several different surface treatments available for steel sheets, including galvanizing, powder coating, painting, and plating. These treatments help to protect the steel from corrosion, improve its appearance, and enhance its durability.

- Q: What does "steel plate 10t" mean in the specification column of engineering material?

- 10T refers to the steel plate thickness of 10mm.Steel plate is made of molten steel, cooled and compressed into flat steel.The steel plate is flat, rectangular, and can be rolled directly or cut from a wide strip of steel.

- Q: What is the difference between a smooth and textured steel sheet?

- A smooth steel sheet has a flat and even surface, while a textured steel sheet has a pattern or texture imprinted on its surface, providing a visual or tactile effect.

- Q: Can steel sheets be perforated for ventilation purposes?

- Indeed, ventilation purposes can be achieved through the perforation of steel sheets. Multiple industries and applications frequently employ perforated steel sheets whenever ventilation is necessary. By incorporating perforations into the steel sheets, airflow is enabled while ensuring the material's structural integrity remains intact. The customization of these perforations allows for ventilation requirements to be tailored, encompassing factors like hole size and pattern. Notably, HVAC systems, industrial equipment, architectural endeavors, and acoustic panels, among other applications, greatly benefit from the utilization of perforated steel sheets. This is due to the crucial need for a harmonious equilibrium between ventilation and strength.

- Q: Can steel sheets be used for food storage containers?

- No, steel sheets are not typically used for food storage containers as they can corrode and lead to contamination of the food. Food-grade materials like stainless steel or food-safe plastics are preferred for this purpose.

- Q: Are steel sheets resistant to mold and mildew?

- No, steel sheets are not resistant to mold and mildew.

- Q: Can steel sheets be cut to custom sizes?

- Yes, steel sheets can be cut to custom sizes.

- Q: Can steel sheets be used for insulation in buildings?

- No, steel sheets cannot be used as insulation in buildings. Steel is a highly conductive material, meaning it allows heat to pass through it easily. Insulation, on the other hand, is designed to resist the flow of heat, keeping the interior of a building warm in winter and cool in summer. Materials such as fiberglass, foam, or cellulose are commonly used for insulation as they have low thermal conductivity.

- Q: Can steel sheets be used for solar panel mounting?

- Yes, steel sheets can be used for solar panel mounting. Steel is a strong and durable material that can provide a stable support structure for solar panels. It has the necessary strength to withstand the weight of the panels, as well as the external forces such as wind and snow loads. Additionally, steel sheets can be easily fabricated and customized to meet the specific requirements of the solar panel installation.

Send your message to us

Prepainted Galvanized Steel Sheets in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords