circular column formwork wooden lightweight for concrete column round pillar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

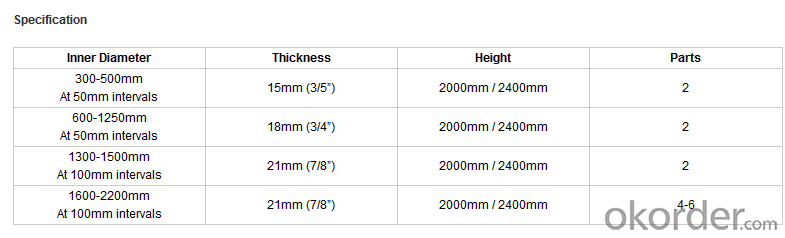

Specification

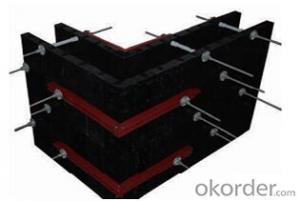

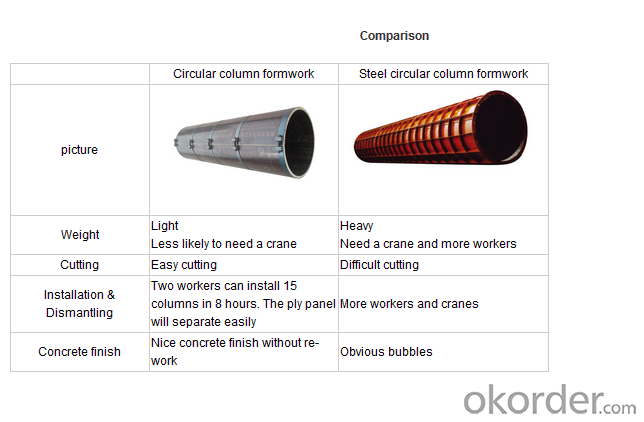

wholeasale circular column formwork customized size quick form easy cuting

1. Made of plywood, light weight, easy handling

2. Grooves prevent the leakage of concrete

3. Easy cutting

4. Efficient installation and dismantling

5.Nice concrete finish without re-work

Application

For concrete forming of circular columns

Installation

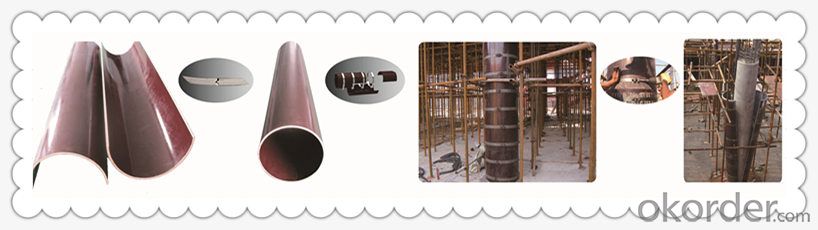

1.Treat inner ply film with concrete release agent firstly.

2.Fix the steel belts horizontally according to the lines.

3.If the height is more than 3000mm , please install it as the indication below.

4.Fromfeedback on site, only 2 skilled workers can install 15 circular columns in 8 hours.

Dismantling

Simply untie the steel belts and the ply will separate easily.

Maintenance & Storage

Lightly treat the ply film with oil before next usage.

place the formwork vertical, away from direct sunlight and water.

Package and shipment

On Site

- Q: In the case of setwe, the stability stress ratio of steel frame beam is 0? PKPM

- The component is not possible because the upper compression crushed, because when the upper part of the lower crushing, would pull out.So there is no point in discussing the compressive stress here

- Q: What are the considerations for selecting the appropriate formwork for different concrete curing methods?

- When selecting the appropriate formwork for different concrete curing methods, there are several considerations that need to be taken into account. These considerations include the type of curing method being used, the desired outcome and appearance of the concrete, the strength and durability requirements, the complexity of the project, and the budget available. Firstly, the type of curing method being used plays a significant role in determining the formwork. For instance, if the project requires wet curing, where the concrete is kept moist for an extended period, the formwork needs to be able to withstand the moisture without warping or deteriorating. In contrast, if the project requires dry curing, where the concrete is allowed to cure without additional moisture, the formwork needs to be able to provide sufficient support and prevent any deformations during the curing process. Secondly, the desired outcome and appearance of the concrete are important considerations. Some formwork systems allow for intricate designs and shapes to be created, such as curved or textured surfaces. In such cases, reusable or adjustable formwork systems may be preferred to achieve the desired aesthetic. On the other hand, if the project calls for a plain, simple finish, traditional timber formwork may be more cost-effective and suitable. Thirdly, the strength and durability requirements of the concrete need to be considered. Certain formwork systems, such as steel or aluminum, provide higher tensile strength and can withstand greater pressures. This is particularly important when dealing with large and complex structures or when working with high-strength concrete mixes. Additionally, the formwork needs to be able to withstand any potential vibrations during the pouring and consolidation process. The complexity of the project also plays a role in selecting the appropriate formwork. If the project involves intricate shapes, curves, or sloping surfaces, modular formwork systems that can be easily adjusted and adapted may be preferred. Conversely, for simpler structures with straight walls or slabs, traditional timber formwork may be more practical and cost-effective. Lastly, the budget available for the project is a crucial factor. Different formwork systems have varying costs associated with them. For instance, reusable or adjustable formwork systems may have a higher initial cost but can be more economical in the long run due to their reusability. On the other hand, traditional timber formwork may be less expensive initially but may require more labor and maintenance costs. In conclusion, selecting the appropriate formwork for different concrete curing methods requires careful consideration of the curing method, desired outcome, strength requirements, complexity of the project, and available budget. By evaluating these factors, one can choose the most suitable formwork system that will ensure a successful and efficient concrete curing process.

- Q: Can steel frame formwork be used for curved or circular structures?

- Yes, steel frame formwork can be used for curved or circular structures. Steel formwork is flexible and can be easily shaped to fit the desired curve or shape of the structure. The steel frames can be adjusted and modified to create the desired form, ensuring accuracy and precision. This flexibility allows for the construction of unique and complex curved or circular structures with ease. Additionally, the strength and durability of steel make it an ideal choice for formwork, ensuring that it can withstand the pressures and forces exerted during the construction process. Overall, steel frame formwork is a versatile and reliable solution for forming curved or circular structures.

- Q: How does steel frame formwork prevent leakage or seepage of concrete?

- The design of steel frame formwork aims to avoid concrete leakage or seepage by creating a tight and secure enclosure for the poured concrete. The steel frame functions as a robust barrier, keeping the concrete in place and preventing it from escaping or seeping out. A distinguishing feature of steel frame formwork is its ability to create a smooth and uninterrupted surface. The steel panels are joined together using sturdy locking mechanisms, leaving no gaps or openings through which the concrete can escape. This strong and secure connection between the panels effectively prevents any leakage or seepage. Furthermore, steel frame formwork is constructed to withstand the pressure exerted by the wet concrete during the pouring and curing process. The steel panels are sturdy and inflexible, ensuring that they can endure the weight and pressure of the concrete without bending or distorting. This structural integrity of the steel frame further guarantees the absence of any leakage or seepage. Additionally, steel frame formwork is often coated with special sealants or coatings that enhance its impermeability. These coatings provide an extra layer of protection against potential leaks or seepage. They establish a waterproof barrier that stops water or moisture from infiltrating the concrete and causing damage. In conclusion, steel frame formwork presents an effective solution for preventing concrete leakage or seepage. Its smooth and uninterrupted surface, structural integrity, and supplementary protective coatings ensure that the concrete remains securely contained within the formwork, resulting in a sturdy and long-lasting structure.

- Q: How does steel frame formwork handle extreme weather conditions?

- Steel frame formwork demonstrates exceptional durability and can endure the most severe weather conditions. Its robust and steadfast structure guarantees its integrity, even in the face of inclement weather such as heavy rainfall, strong gusts, or extreme temperatures. A primary benefit of utilizing steel frame formwork lies in its resistance to corrosion. Steel, as a material, possesses an inherent resistance to rust, rendering it ideal for construction undertakings in regions characterized by high humidity or regular exposure to water. This resistance to corrosion ensures that the formwork remains structurally sound and maintains its integrity, even when confronted with adverse weather conditions. Additionally, steel frame formwork is designed to offer exceptional stability and load-bearing capacity. Consequently, it can endure high wind velocities without succumbing to damage or deformation. The robust nature of the steel frame formwork ensures that it can withstand extreme weather conditions without compromising the safety of the construction site. Furthermore, steel frame formwork is frequently designed with a protective finish or coating that further heightens its resistance to weather elements. This protective layer provides supplementary safeguards against moisture, UV rays, and other environmental factors, thereby prolonging the lifespan of the formwork and guaranteeing its durability in the face of extreme weather conditions. In conclusion, steel frame formwork proves to be an outstanding choice for construction ventures situated in areas prone to severe weather conditions. Its resistance to corrosion, stability, and protective finishes establish it as a dependable and long-lasting solution, capable of effortlessly handling even the most challenging weather conditions.

- Q: Can steel frame formwork be used for both large and small-scale construction projects?

- Steel frame formwork is applicable to construction projects of both large and small scales. It is renowned for its durability and strength, which renders it suitable for various construction projects, irrespective of their size. Stability and support are guaranteed by the steel frame, ensuring that the formwork can endure the pressure and load of the concrete during the casting process. Moreover, the design of steel frame formwork allows for flexibility and easy assembly and disassembly, enabling efficient utilization in projects of different sizes. Its reusability makes it a cost-effective solution for both large and small-scale projects since it can be used multiple times. In conclusion, steel frame formwork is a versatile and dependable option for construction projects of any magnitude.

- Q: Can steel frame formwork be used for prefabricated concrete elements?

- Yes, steel frame formwork can be used for prefabricated concrete elements. Steel frame formwork is a versatile and durable system that can be easily adjusted and reused for various concrete construction projects. It provides a rigid structure and precise alignment for pouring concrete, ensuring the desired shape and dimensions of the prefabricated elements. Steel frame formwork also offers greater flexibility in design and can accommodate complex shapes and structures. Additionally, its strength and stability make it suitable for handling the weight and pressure exerted by the concrete during the curing process. Overall, steel frame formwork is a viable option for creating high-quality prefabricated concrete elements.

- Q: What are the principles of the layout and spacing of steel structure engineering framework

- Square column and rectangular column is the basic column of multi story frame structure commonly used, the column should be used in 6 ~ 9m.When the column is determined, the grillage naturally according to the column grid layout. The main beam of the frame should be arranged on the frame column according to the frame direction.Generally need to be installed in the main beam according to the requirements of the floor beam, the spacing can be 3 ~ 4m.

- Q: Can steel frame formwork be used for both monolithic and modular slab construction?

- Yes, steel frame formwork can be used for both monolithic and modular slab construction. The versatility of steel frame formwork allows for easy adaptation to different construction methods, making it suitable for both monolithic (continuous pour) and modular (precast or prefabricated) slab construction.

- Q: Can steel frame formwork be used for the construction of industrial structures?

- Yes, steel frame formwork can be used for the construction of industrial structures. Steel frame formwork is known for its durability and strength, making it suitable for the heavy loads and complex designs often required in industrial construction. It offers stability and precision in creating concrete structures, ensuring the integrity and safety of the industrial buildings. Additionally, steel frame formwork can be easily assembled and disassembled, allowing for efficient and cost-effective construction processes.

Send your message to us

circular column formwork wooden lightweight for concrete column round pillar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords