Wood Framed Aluminum Tin Sheets - Checkered Aluminum Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminum Sheet AA1100 for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminum Sheet AA1100 for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminum Sheet AA1100 for Automotive Body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

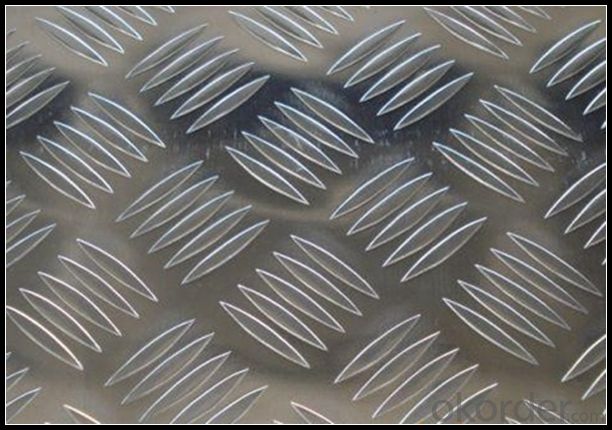

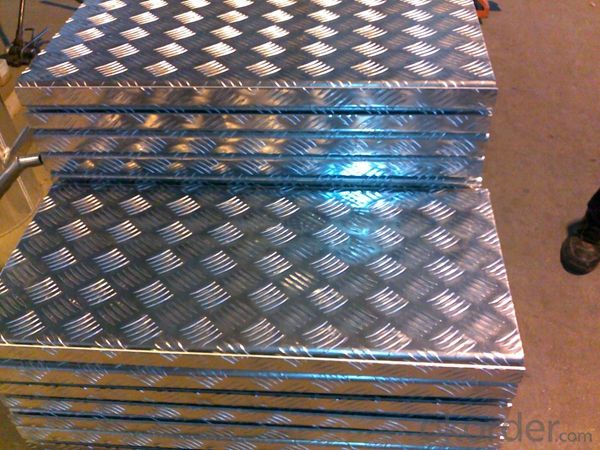

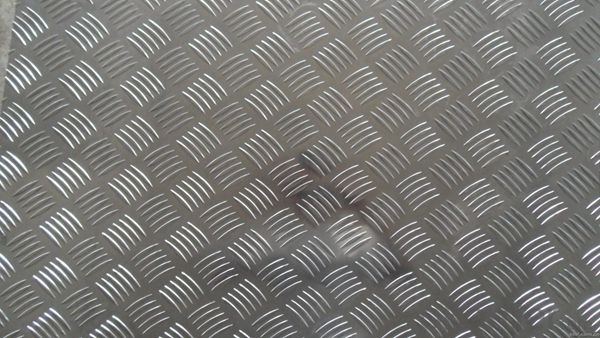

5. Image of Checkered Aluminum Sheet AA1100 for Automotive Body

6. Package and shipping of Checkered Aluminum Sheet AA1100 for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for industrial shelving?

- Certainly, industrial shelving can indeed make use of aluminum sheets. Aluminum, being a material that is lightweight and durable, offers numerous benefits for industrial shelving applications. It possesses resistance against corrosion, making it suitable for environments that face exposure to moisture or harsh chemicals. Moreover, the strength-to-weight ratio of aluminum proves advantageous, enabling the creation of robust shelves capable of supporting heavy loads while remaining relatively light in weight. Furthermore, aluminum is low-maintenance as it does not necessitate painting or sealing like other metals. Consequently, aluminum sheets are an incredibly practical option for industrial shelving due to their durability, resistance to corrosion, and lightweight characteristics.

- Q: Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is corrosion-resistant and has good strength-to-weight ratio, making it suitable for storing various chemicals safely.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: What is the thermal conductivity of aluminum sheets?

- Aluminum sheets exhibit high thermal conductivity, reaching around 237 W/m·K. This quality endows aluminum with exceptional heat conduction capabilities, enabling efficient heat transfer between different regions. Consequently, aluminum sheets find widespread application in various domains, including heat sinks, radiators, and cooking pans.

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling, where a large ingot of aluminum is heated and passed through a series of rollers to reduce its thickness and increase its length. This continuous rolling process is repeated until the desired thickness is achieved, and the aluminum sheet is then cut into various sizes and shapes.

- Q: What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is generally considered to be excellent. Aluminum is a highly malleable metal, meaning it can be easily shaped or formed into various designs without cracking or breaking. This characteristic makes aluminum sheets highly desirable for a wide range of applications, including automotive body panels, aircraft components, and household appliances. Additionally, aluminum has good ductility, which allows it to be stretched and bent without losing its structural integrity. However, it is important to note that the formability of aluminum sheets can vary depending on the alloy composition, thickness, and processing conditions. Therefore, it is essential to consider these factors when choosing the appropriate aluminum sheet for a specific application.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, in general, aluminum sheets are commonly available in standard sizes of 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are widely used in construction, manufacturing, and other industries due to their versatility and compatibility with standard equipment and processes. However, it's important to note that aluminum sheets can also be custom cut or ordered in different sizes to meet specific project requirements.

- Q: Status of aluminum sheet F

- Status of aluminium plateThe F is free, and the aluminum sheet state is not limited. It is suitable for the products which have no special requirement for the working hardening and the heat treatment conditions in the forming process. The mechanical properties of the products in this state are not specifiedO is an annealed state, that is, a fully soft state, suitable for fully annealed products with minimum strength

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

Send your message to us

Wood Framed Aluminum Tin Sheets - Checkered Aluminum Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords