30 X 37 Embossed Aluminum Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Embossed Aluminum Sheet AA1100 for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Embossed Aluminum Sheet AA1100 for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Aluminum Sheet AA1100 for Automotive Body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

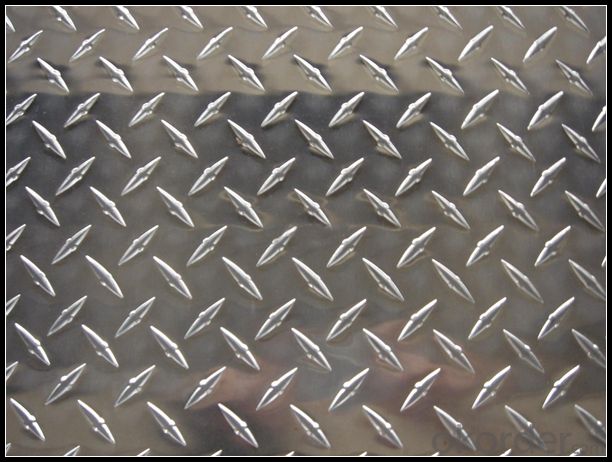

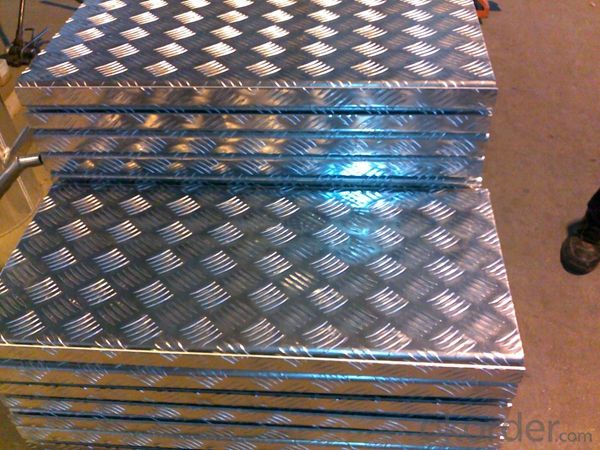

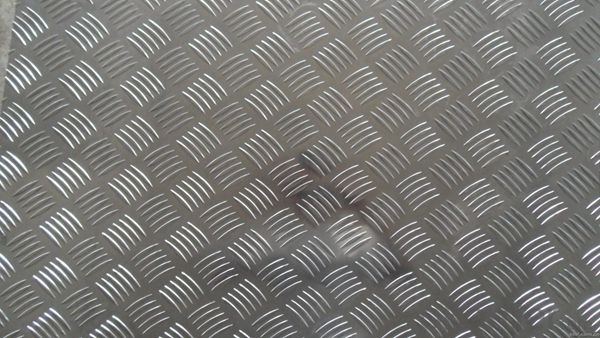

5. Image of Embossed Aluminum Sheet AA1100 for Automotive Body

6. Package and shipping of Embossed Aluminum Sheet AA1100 for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to create new products. Aluminum is highly recyclable, and the process of recycling it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for a wide range of applications, from packaging to construction materials. The use of recycled aluminum helps reduce waste, conserve resources, and lower environmental impact.</p>

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: Can aluminum be either conductive or magnitized?

- Aluminum is conductive. In fact at one point in time it was used as an alternative to copper wiring for home electrical wiring. (There were problems, so it is no longer used).

- Q: What is the standard thickness of aluminum sheets used for exterior building applications?

- <p>The typical thickness of aluminum sheets used for building exteriors ranges from 0.7mm to 1.2mm. This range is suitable for applications such as facades, cladding, and roofing. The specific thickness can vary depending on the structural requirements, wind loads, and the overall design of the building. Thicker sheets may be used for more robust structures or in areas with higher wind pressures, while thinner sheets can be used for lighter applications or when a more aesthetically pleasing finish is desired.</p>

- Q: 6061-T6 can aluminum sheets be bent?

- You ask if the two batch of aluminum material has been aging, the hardness of the aluminum after aging is higher than before the aging. Another aluminum material from the extrusion after the storage time and environment also related. You can measure the hardness of the two batch of aluminum.

- Q: This question asks for a comparison of the cost of aluminum sheets with other building materials.

- <p>Aluminum sheets are generally considered cost-effective compared to other building materials, especially when considering their long-term benefits. They are relatively inexpensive to produce and install, and their low maintenance requirements can save costs over time. However, their initial cost may be higher than some materials like wood or vinyl. Aluminum's resistance to corrosion and weathering means it lasts longer, which can offset the higher upfront cost. In contrast, materials like steel might be more expensive due to their weight and the cost of corrosion protection, while concrete and masonry are typically more costly for both materials and labor. The cost-effectiveness of aluminum can vary based on regional prices, specific project requirements, and the type of aluminum product (e.g., thickness, finish).</p>

- Q: Are aluminum sheets suitable for chemical processing equipment?

- Under certain conditions, chemical processing equipment can utilize aluminum sheets. Aluminum demonstrates good resistance to a variety of chemicals, including acids and alkalis. It exhibits exceptional resistance to corrosion in acidic surroundings like hydrochloric acid and sulfuric acid, as well as alkaline solutions such as sodium hydroxide. However, it is crucial to acknowledge that aluminum is not universally suitable for all chemical processes. It is not advisable to employ it in applications involving potent oxidizing agents like nitric acid or chromic acid, as these substances can swiftly corrode aluminum. In addition, aluminum is incompatible with certain organic solvents and can react with them, leading to equipment degradation or malfunction. In certain situations, aluminum can be employed in chemical processing equipment by employing protective coatings or linings to bolster its resistance against specific chemicals. This approach can enhance its longevity and broaden its range of applications. In conclusion, although aluminum sheets can be appropriate for chemical processing equipment in numerous cases, it is imperative to carefully evaluate the specific chemicals and operating conditions involved to ensure compatibility and steer clear of potential corrosion or malfunction issues.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are known for their excellent weather resistance properties. Due to their inherent corrosion resistance, aluminum sheets can withstand exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor applications. The protective oxide layer that naturally forms on the surface of aluminum provides a barrier against moisture, preventing the metal from reacting with oxygen and thus reducing the risk of corrosion. Additionally, aluminum sheets have high resistance to UV radiation, making them resistant to fading or discoloration caused by prolonged exposure to the sun. Overall, aluminum sheets offer exceptional performance in terms of weather resistance, making them a reliable choice for a wide range of outdoor applications, including roofing, siding, and outdoor signage.

- Q: Are aluminum sheets suitable for chemical storage tanks?

- Yes, aluminum sheets can be suitable for chemical storage tanks depending on the specific requirements of the chemical being stored. Aluminum is known for its excellent corrosion resistance, which makes it suitable for storing many chemicals. It forms a protective oxide layer that prevents further corrosion, even when exposed to harsh environments. However, it is important to consider the compatibility of the chemical with aluminum. Some chemicals, such as strong acids or bases, may react with aluminum and cause corrosion or other undesirable reactions. In such cases, alternative materials like stainless steel or fiberglass-reinforced plastic (FRP) may be more suitable. Additionally, the thickness and grade of the aluminum sheets should be chosen carefully based on the specific chemical being stored and the tank's intended use. Thicker sheets may be necessary for storing highly corrosive or hazardous chemicals, while thinner sheets may be sufficient for less aggressive substances. Overall, aluminum sheets can be a suitable choice for chemical storage tanks, but it is crucial to carefully evaluate the chemical compatibility and select the appropriate thickness and grade of aluminum to ensure safe and reliable storage.

Send your message to us

30 X 37 Embossed Aluminum Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords