Menards Suspended Ceiling Grid System for PVC Facing Gypsum Ceiling Tile Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling Tee Bar Grid System for PVC facing Gypsum Ceiling Tile Board

Raw material

Material:high-quality hot dipped galvanized steel coil

Surface treatment:Baking Painting

Usage

(1)Ceiling supporting structure for installing ceiling boards.

(2)Ceiling decoration for beauty.

Application

Office, factories, hotels, theaters, external corridor, washroom, bathroom, etc.

Characteristics of ceiling t bar

1) More elegant in style and beauty, easy match to decoration

2) Good strength, high quality

3) Cauterization-resistance, water-resistance

4) Rustproof, fire resistance, stainless, rust resistance & convenient application

5) High Quality Material, Moisture proof, anti-corrosive, non-deforming, fadeless

6) High precision, high symmetry, high close fitting

7) Strong bearing capacity

8) Safe, firm and easy to match with all kinds of mineral fiber board, aluminum ceiling and gypsum board.

9) Surface color can be stable for 10 years by indoor use

10) Durable service life (More than 5 years)

11) Rust resistance, with galvanized level 80g/m2

12) Loading capacity :≥15kgs/m2

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

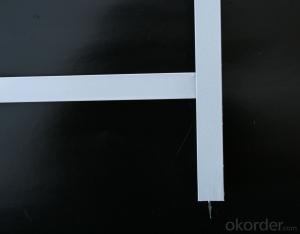

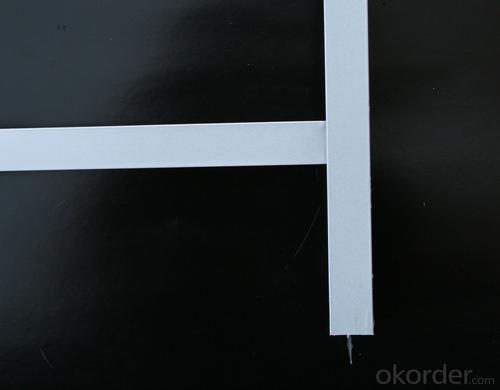

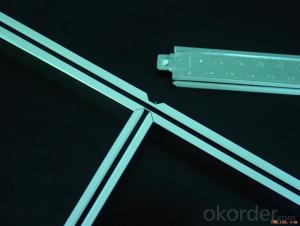

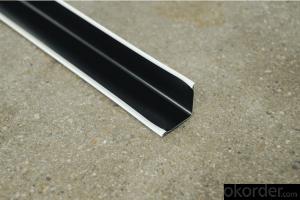

Pictures

- Q: Φ8 light steel keel boom is how much?

- M8, then about 300 kilograms of it, a single boom of the tensile strength, the main problem is the line wire.

- Q: I want to do the arc of the ceiling, but the wood keel is not strong, I would like to ask how to use light steel keel hanging?

- Mu Fang plus milky white plastic should be very strong, light steel keel bad account

- Q: Paper gypsum board is B1 grade fireproof material, why installed in the light steel keel can be treated in accordance with A-class fireproof material? Partition wall is to have mineral wool, the ceiling does not seem to need it.

- Can not, I am Kaiyuan City, Liaoning Province, brilliant production of fire board board manufacturers, used plaster board or decoration companies are aware of gypsum board it is not waterproof water and moisture is very serious, but also very vulnerable The force will be broken and broken, it is not suitable for home decoration and engineering decoration now, and now the fire board has become an alternative gypsum board to become a quality and cheap multi-purpose multi-purpose decorative plate, so subject to The market's consumers wide acclaim, and located in Kaifeng City, Liaoning Province, Qingyun Town, brilliant board industry is in the price and quality of fire board has done a very good demonstration and take the lead in its director Jiang Baoyu is the Fire board This kind of sheet through years of research and exploration, to produce a variety of fire board products, these products are affected to the insulation and waterproofing and fire not only the real green also save unnecessary renovation costs and prices, the current Kaiyuan City Brilliant plate produced by the fire products have reached the national A1 level fire standard, 135 and then 91000 is the last 140 hope to work with you.

- Q: Light steel keel how long

- How long can be customized with the manufacturer can be. General 4 meters long

- Q: i just leased a unit in a new plaza. im going to put a barbershop in it. what i want to do is to remove the suspended grid ceiling so it can make the shop look bigger. i know their is sometype of requirement for the ac and i cant just leave it out in the open.. what do i need to do to meet the requirements? ive seen that they put some type of cover over it..

- The space between the drop ceiling and the actual ceiling is most likely being used as a return plenum. That is, the entire ceiling is your return duct. You will notice there are a couple egg crate tiles in the ceiling that allow for return air to get above the drop ceiling.The supply ducts are no doubt wrapped to avoid the dripping as stated by Dart otherwise you wouldn't have got the C.O. in the first place. The return is filled with hot, humid air that would've condensed on the cool ductwork and dripped onto the drop ceiling, but i doubt this is the case. They are insulated. If you were to remove this ceiling, you would have to spend the money to run return duct to the various points in the barber shop to ensure air changes and proper CFM (cubic feet per minute) exchange. Not to mention the reason a drop ceiling is there in the first place is to make the room smaller so the unit won't run as much and cost loads of money. Which brings up another problem. If you raise the ceiling in the room, you've just changed the heating and cooling demands for that roof unit and it may not be able to keep up. My advice is to leave the celing and all as it is. If you want to do something with it, why not paint a design on the tiles? If you know an artist, or artistic yourself, do a :Sisitine Chapel thing and have a mural on the ceiling. The tiles come down easily and it would be quite the conversation piece. OK so i'm not a decorator........

- Q: Was tearing out an acoustical ceiling grid while the electrician was taking out the fluorescent lights. What I didn't know was that he was taking them out hot. He left wires uncapped and the hot leg touched the grid I had ahold of. It grabbed me for about 3 seconds. My head snapped back and I could feel my mouth open to scream but nothing came out. I was aware of everything going on and my only thought was that I was going to die. Luckily I fell backwards off the ladder. I had burns on my left hand and right forearm and stomach. Everywhere I was touching the grid. My arms were cherry red from the elbows down for awhile. 2 weeks later my arms still tingle and my wrists have a terrible burning pain every couple of days. It was a very religious experience. I did kick the electrician off the job. My question is did the current go across my chest or through my heart from one arm to the other and could it have killed me if I hadn't fallen from the ladder. I guess I'm lucky I'm 6'4 and 250 lbs. I feel lucky anyway.

- Yes I must agree with you, you are very lucky , phew !..........

- Q: each point on the grid. The weight of each 4x4 area is 144# ( square footage is 9# PSF ) which I divide into four seperate areas and come up with a reaction so I know what spring to use at each point. The basic areas are easy to calculate because it's either rectangular or square but some areas are cut up, for example there are areas shaped like an L on the grid with two rectangular sides and I don't know how to get their reaction because there are more than four points. Could someone show me a formula for this?

- Sounds like you will probably need to break up the oddly shaped areas, and consider them as a collection of rectangles. However, my understanding is still a little fuzzy. What's this reaction stuff? I don't have a clear picture of the layout in my head.

- Q: I am looking for the fire resistance of the building components, see the middle of the house wall with "steel keel" and "light steel keel", what is the difference between the two? What do I want to know is that the two are different in terms of function and practical application? What are the advantages and disadvantages?

- However, steel keel is made of pure steel, heavier weight, nature and light steel keel almost, is the difference between materials, light steel keel is a thin steel plate, steel keel is built with pure steel.

- Q: How close to the original ceiling can I hang a drop ceiling? I know you need a certain amount of space between the original ceiling and the gridwork of the drop ceiling so you can get the tiles in... I am remodeling my basement and it only has 8' ceilings now, so I want to retain as much headroom as possible. Thank you...

- If I remember correctly, you can do it in 3 inches, or maybe slightly less.I had a 7 foot ceiling to work with and in a few spots because of pipes we did it almost flush.You can slide the tiles in before you put up another line of grid, then pop them in.

- Q: In the decoration of light steel keel + blockboard + gypsum board + latex paint this practice? I think with light steel keel is like a gypsum board is like, and now the construction side that there is no way to let the sky keel will be down one meter, can only do with light steel keel. I think they are not lying to me. Please know the big friends help out

- Do not all the same, first nailed the wood on the wall, then the wood keel fixed in the above, and then pull down a few wires from the ceiling hanging keel is not on the line? But the gypsum board brush latex paint is very lacquer, brush out the gypsum board sound-absorbing breathable characteristics of the no

Send your message to us

Menards Suspended Ceiling Grid System for PVC Facing Gypsum Ceiling Tile Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords