Butterfly Valve The Pin Spline or Square Connection China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wafer butterfly butterfly plate installed on the diameter of the pipe direction. Cylindrical channels in butterfly valve body, disc disc around the axis of rotation, rotation Angle for 0 ° and 90 °, can have the effect of flow control, when the butterfly plate rotation to 90 °, the maximum opening of the valve. The wafer butterfly valve has simple structure, small volume, light weight, only by a few parts. And only need to rotate 90 ° can rapid opening and closing, simple operation, at the same time, the valve has good flow control characteristics.

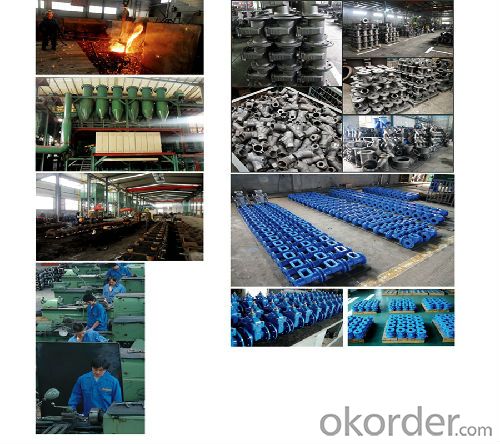

Our product features are as follows:

1.Newly developed facilities ensure high and stable quality.

2.Enable to supply UL/FM valves.

3.Experienced technology

4.Excellent after-sale service to satisfy customers.

5.Sufficient capacity ensures prompt delivery.

6.Continuous quality improvement and new designs development.

7.Reasonable and stable price

8.Meets different countries standards,such as ANSI,DIN,BS etc.

Packaging Details: Plactic bag+Paper cover+Plywood cases

Delivery Detail: Within 20 days

Specifications

Wafer type butterfly valve

1.Design standard:ISO,BS,API

2.DN40-DN1200

3.PN10/PN16/PN25

4.Center lined disc

Technical Data

DN40-DN1200mm PN1.0-1.6MPa

General Design:ISO 5752 / BS 5155 / API 609

Body: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel

Seat: EPDM, PTFE, NBR,Viton

Stem: Stainless Steel, Steel,

Disc: Ductile Iron with Nickel Coating,Ductile Iron with Nylon Coating, Stainless Stee 304/316l, Alu-Bronze,Duplex steel

Flange Connection:DIN,ANSI,JIS,BS

Material Specification | ||

Part | Material | ASTM |

Valve Body | cast iron | A126 Class B |

ductile iron | A536 Gr.65-45-12 | |

Valve Disc | ductile iron | A536 Gr.65-45-12 |

bronze | B148 C95400 | |

stainless steel 304 | A351 CF-8 | |

stainless steel 316 | A351 CF-8M | |

Valve Shaft | stainless steel 410 | A276 S 410 00 |

stainless steel 431 | A276 S 410 00 | |

Valve Seat Ring | EPDM/NBR

| |

O-Ring | EPDM/NBR

| |

Bushing | PTFE

| |

bronze | B62 C83600 | |

Dimensions

| DN | mm | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| inch | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | |

| A | 68 | 80 | 89 | 95 | 114 | 127 | 139 | 175 | 203 | 242 | 267 | 309 | |

| B | 110 | 161 | 175 | 181 | 200 | 213 | 226 | 260 | 292 | 337 | 368 | 400 | |

| C | 24 | 30 | 30 | 30 | 30 | 30 | 30 | 34 | 34 | 34 | 40 | 52 | |

| L | 33 | 42 | 45 | 45 | 51 | 55 | 55 | 60 | 67 | 76 | 76 | 102 | |

| DN | mm | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 900 | 1000 | 1200 | - |

| inch | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 36 | 40 | 48 | - | |

| A | 327 | 361 | 412 | 459 | 472 | 527 | 554 | 605 | 668 | 728 | 855 | - | |

| B | 422 | 490 | 533 | 562 | 540 | 626 | 660 | 666 | 720 | 806 | 938 | - | |

| C | 52 | 64 | 70 | 70 | 70 | 95 | 95 | 95 | 130 | 130 | 150 | - | |

| L | 114 | 127 | 151 | 151 | 172 | 165 | 167 | 188 | 203 | 216 | 276 | - | |

Product Features

Wafer type flanged body style fit between FF or RF flanges

PTFE bushing ensure the maximum shaft support and centralized alignment

360°polished disc assures positive on-off

Hard-Backed Cartridge seat or Edge-Boot seat

The pin,spline or square connection are all available

Universal ISO 5211 mounting pad.

- Q: I got my timing belt done on a 1999 Civic Si on September 26 @ 113,699 miles. at 116,9xx miles I bent a valve on my third cylinder. How likely is it that the timing belt is the reason why this happened? I heard that if the timing belt is a tooth or so off, it could bend a valve. So is it likely that this could have happened? Anyway to check?

- A TDI has no valve to piston clearance as a results of the indisputable fact that's a diesel and has a extreme compression ratio. i'm a mechanic myself and hate to slam different techs yet it truly is clearly a screw-up on his section. There are some issues that would have exceeded off even if the shop he works at is to blame for the damages. If the tensioner did bend (which I surprisingly doubt exceeded off) then he has recourse by the business business enterprise that man made the tensioner yet to be quite truthful, it truly is only no longer real. similar is going for the snatch problem. that only isn't plausible. good success.

- Q: Why anti condensation of aluminum alloy anti condensation butterfly valve?

- Anti condensation butterfly valve multi-level unique progressive contact seat design, the valve plate in close contact in the process of gradually seat, ensure good sealing performance while reducing unnecessary torque, and the butterfly plate of stainless steel and the inner parts, thereby prolonging the service life of the valve seat, has strong rust and corrosion function. Torque reduction enables the drive to be lightweight and miniaturized. Unique stem seal prevents fluid leakage.

- Q: How do i use a valve spring compressor. It looks like a c-clamp, so don't tell me how to use a smaller one, but the bigger one.Thanks

- save yourself the hassle and throw that thing away go back to your local auto parts store and buy the l shaped spring compresser should be about twenty dollars make sure vehicle is at tdc remove rocker arm bolt remove rocker arms going valve by valve do not mix them up must go in exactly the same order they came out now lightly tap the top of valve with a rubber mallet will help loosen retainers place compresser on rocker arm stud take r.a. nut and tighten till valve locks fall out or can be removed very small dont lose use compressed air to hold valves in place at tdc sorry that should have been first not hard but not easy to do rebuilt 350 motor from the guts out spent alot of money on spring compressers only to find out the simplest one worked the best the one like u got will give u hell i tried napas version craftsman all of them trust me use the L bar

- Q: What does the model D373H-16C of butterfly valve mean?

- For example: Z543H-16C bevel gear flange plate valve, nominal pressure 1.6MPa, the valve body is made of carbon steel valves valve name according to the mode of transmission, connection form, structure, lining material and type name. But here in the name of the content shall be omitted: (1) the connection form: "flange" (2. Structure: a): valve "rod" and "flexible" and "rigid" and "single gate"; B: "straight" stop valve and throttle valve; C: ball "floating" and "one-stop"; D: butterfly valve "vertical plate type"; E: the diaphragm valve "roof"; F: Cock "filler" and "one-stop"; G: check the "one-stop" and "single"; H: "safety valve is not closed. (3) the valve seat sealing surface material in the material name Said. I have just engaged in the valve industry, mainly to do www.ssfmsh traps, but also hope that we learn from each other and make progress together

- Q: What are single eccentric and double eccentric in butterfly valves? What's the difference, please explain in detail?

- Three eccentric butterfly valve: to high temperature, must use hard seal, but the leakage is large; to zero leakage, must use soft sealing, but not high temperature. In order to overcome the double eccentric butterfly valve this contradiction, and the butterfly valve for third times eccentric. The so-called third eccentric, that is, the shape of the sealing pair is not a positive cone, but rather oblique cone.Variable eccentric butterfly valve: variable eccentric butterfly valve is unique in that the valve stem axis installation disc is a three shaft type structure, the three stem shaft two concentric shafts, while the center section of the shaft center line and both ends of a center axis deviation distance, the installation disc in the middle section of the shaft. The eccentric structure makes the disc become double eccentric at full open position, and becomes eccentric when the disc rotates to the closed position. Due to the action of the eccentric shaft, near the close, the butterfly plate sealed to the seat by moving a distance within the cone, the butterfly plate and the valve seat sealing surface to achieve consistent and reliable sealing performance.

- Q: I was wondering if someone could tell me the manufacturing date on this aircraft engine valve.

- Wow Hannah! That's a cool find for sure! It appears to be possibly a valve for a radial aircraft engine as it looks very similar to ones i've seen used in Pratt+Whitney R3350's etc. It looks like it could probably date to the 1940's up thru the 1950's. Look for a Part Number stamped on the valve or on the box. After WW2 there were all kinds of manufacturers making parts for airplanes. Many were gobbled up by competitors, converted to manufacturing other products or went out of business altogether. However, a few did hang on....and I think this may be what has become of Thompson Aircraft today.... Thompson Aerospace, Inc 22431 Antonio Parkway B160-102 Rcho Sta Marg, CA 92688-2804

- Q: For example, the arrow above is from left to right, and the direction of my current is from right to left. Is that ok? I have a diameter of 700 of the hard seal butterfly valve is so installed, but it will leak water, it will not leak, very serious

- From the above example, it can be concluded that the arrow direction of the butterfly valve body refers to the direction of the pressure of the medium. Before the installation, the user must know the direction of the pressure of the valve after the valve is closed. The direction of the arrow of the free valve body is in accordance with the direction of the pressure of the medium, so that the correct use can be achieved, and the tightness of the valve body is kept in good condition.

- Q: How can the flange butterfly valve be installed on the pipe?

- Outlet pipe configuration.If in the pipeline, the valve in order to do not bear the direction of the force and bending moment, it is best to set the valve at the exit side of the expansion joint. Valve opening and closing valve water pressure should not be borne by the foot, but through the valve flange, by the pipeline to bear as well.Butterfly valve structure is generally shorter length, and its butterfly plate will be extended to adjacent pipes or other parts, so be careful not to collide with other parts and interference. And to prevent the error matching pipe diameter greater than C and collide with the butterfly plate.Butterfly valve as a regulator, just adjust the flow and pressure. The valve is regulated by loss of pressure.

- Q: My quot;check engine soonquot; light came on yesterday and soon after that I took it to the nearest Midas to have the diagnostic test run on it - they stated I needed an ERG valve. I have no clue what it is and was told that it could run $160. - $300. for my 1900 Astro van. what is an ERG valve? I have noticed that my van has a low humming sound when I'm driving it.

- The EGR valve is there to reduce nitrous oxide emissions and lower the temp of the combustion charge. This has the affect of reducing the octane requirement of the engine. This isn't a bad thing. When the valve hangs open, the thing will run bad at idle and could even die. The thing is, the valve could be perfectly fine and the sensor could be bad. Since some states won't give you a sticker if the light is on, you're probably stuck with replacement.

- Q: What type of butterfly valves do you have in DN125?

- 125D42X: manual double eccentric flange butterfly valve 125D3 (6, 9) 42X: worm (gas, electricity) double eccentric flange butterfly valve125D41X: manual single eccentric flange butterfly valve 125D3 (6, 9) 41X: worm (gas, electricity) moving single eccentric flange butterfly valve125D43H: manual three eccentric flange butterfly valve (hard seal)125D3 (6, 9) 43H: worm (gas, electricity) move three eccentric flange butterfly valve (hard seal)125D71X manual alignment type butterfly valve125D3 (6, 9) 71X worm (gas, electricity) midline type clip butterfly valve125D3 (6, 9) 73H, worm (gas, electricity) three eccentric pair clip butterfly valve (hard seal)125BD71 (F4) X corrosion resisting fluorine (wrapped) pair clip butterfly valve

Send your message to us

Butterfly Valve The Pin Spline or Square Connection China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords