Butterfly Valve DN150 BS5163 Best Quality Commercial Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

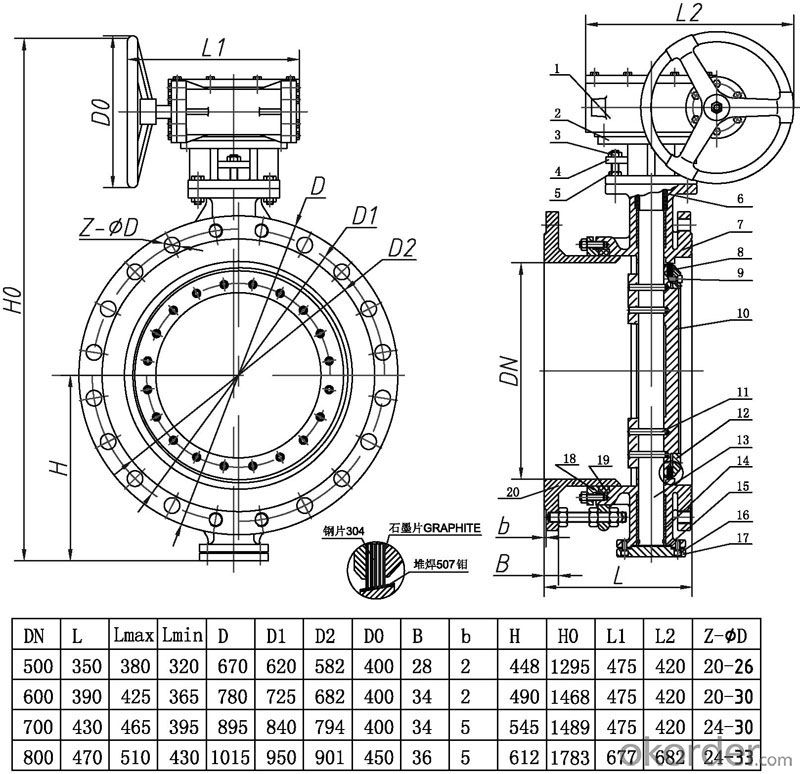

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Transformer butterfly valve and pressure relief valve difference

- The oil immersed transformer pressure release valve is a safety device installed in the transformer, when the internal pressure is less than the limit value of the transformer such as 35kPa, which is in closed state, when the transformer internal fault occurs, a large number of transformer oil by pyrolysis, produce large amounts of gas, the internal pressure of the oil tank increased dramatically when the opening pressure exceeds the pressure release valve when the pressure relief valve opens, the internal oil and gas overflow, to release the pressure, avoid the pressure on the inside of the lead tank cracking or permanent deformation, when the fault of transformer internal end, internal pressure tank to reduce pressure release valve closing pressure, it will automatically shut down to prevent outside air enter the inside of the tank or water.

- Q: Ok, so I took my car in for maintenance (Mustang GT convertible 2002) and the mechanic told me the valve gaskets needed to be replaced and when he gave me the estimate, they were two seperate charges for valve gaskets and valve covers, total of about $250.00 not including labor. Is he trying to rip me off cause I'm a girl by the way? Anyways, I didn't get it done cause it needed something else too and I didn't have enough money so I said I would be back in two weeks. So I called the dealership to inquire about the price and I asked the parts guy for a price on valve gaskets and he was like, I don't know what you mean, we have valve cover gaskets but nothing says just valve gaskets? I told him to give me the price anyways, thinking I would ask my brother (who hasn't tried to help me anyways) and it was $60.00 for both (I need two). How can this be if the other guy was charging me $250.00 for different parts? Help!!! Frustrated and confused, I don't know anything about cars :(

- LOL. No. You don't get away that easily. The valve cover gasket only keeps oil from splashing all over the engine bay. It literally covers the valves, sealing the engine interior away from the general environment. Th head is the part of the engine that the valve cover sits on. It contains the valves, and either the camshaft or the rods that lead to a camshaft deeper in the engine, and of course the rocker assembly. You have to remove all those big bolts along the casting to break the head free, and you'll need a torque wrench to get the pressure right when you're reinstalling it. The head gasket seals the tops of the cylinders [incorporated in the bottom of the head] to the cylinders themselves [bored into the block proper.] Have fun!!!!!

- Q: Why anti condensation of aluminum alloy anti condensation butterfly valve?

- Anti condensation butterfly valve multi-level unique progressive contact seat design, the valve plate in close contact in the process of gradually seat, ensure good sealing performance while reducing unnecessary torque, and the butterfly plate of stainless steel and the inner parts, thereby prolonging the service life of the valve seat, has strong rust and corrosion function. Torque reduction enables the drive to be lightweight and miniaturized. Unique stem seal prevents fluid leakage.

- Q: Okay, so I've been thinking about trying to learn how to play my dad's baritone bugle, but I have no idea how to. If anyone had a good fingering chart for it, that would be great. The bugle has one valve and a trigger. I am a natural flute player and percussionist, so this is my first time playing a brass instrument. Needless to say I am very confused. Call me a noob, I don't care, as long as you get me a fingering chart for a 1 valve baritone bugle. Please help. :)

- Starting below the staff in treble clef - G - open (yeah, intonation heck) C - open D - valve (gap) F# - rotor G - open or valve (gap) Bb - Rotor valve B - Rotor OR valve (pick it) C - open C# - both D - valve D#(Eb) - rotor E - open F - valve F# - rotor G - open G#(Ab) - both (yech!) A - valve or rotor Bb - open or both B - valve or rotor C - open anything above C - dial it in. After seeing this, you'll know why going from G-D to G-F was such a radical improvement. After playing on this relic, you'll really appreciate what some of those corps had to do to sound good.

- Q: What does the triplex of pneumatic butterfly valve mean?

- Air pressure reducing valve, filter, oil mist these three parts

- Q: Fire, the signal butterfly valve flange connection or welding?

- Grooved flange joint, welded flange connection! Wire bonding. Wire to flange connection! In addition, you can choose the groove type signal butterfly valve!

- Q: What are the classification criteria for pneumatic butterfly valves?

- The channel of the valve body inner surface smooth, fluid resistance, high CV value, strong circulation, moderate torque, the use of four seal structure and elastic rubber gasket seat with SI in high temperature aging on the outside sealing surface, zero leakage medium.Pneumatic butterfly, characteristics, there is a slit leaving the valve seat, the product is suitable for use in poor air circulation environment.The pneumatic telescopic butterfly valve is characterized in that the novel and reasonable design, unique structure, light weight, convenient operation, open and close rapidly; in addition to the telescopic valve for regulating and throttling effect, compensation pipeline temperature generated by thermal expansion and contraction function, but also for the installation of valve replacement and maintenance convenience. The sealing parts can be adjusted, replaced, sealed, reliable and so on.

- Q: How to calculate the size of the manual butterfly valve?

- 1. The size of the installation fits only two: the length of the structure and the distance between the flanges.2, butterfly (Manual butterfly) butterfly plate installed in the pipe diameter direction. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is 0 degrees -90 degrees between, when rotates to 90 degrees, the valve opens the card completely. Butterfly valve structure is simple, small size, light weight, only by a few parts. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium passes through the valve body, so the pressure drop produced by the valve is very small, so the flow control characteristic is better. Butterfly valve has an elastic seal and metal seal, two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.

- Q: Whenever sports cars are referred, people talk in terms of 'valves'. ex: v8, v12 etc. What does this all mean? Also they sometimes say that a v8 makes a great noise. why? How does the number of valves effects the performance? Many thanks.

- When talking about car engines, references such as v4, v6, v8, v10 and v12 are not for the number of valves. it is for the number of cylinders. The more cylinders that an engine has, the more fuel it consumes and most of the time, the more horsepower it can make. There are exceptions to this though. Regarding the noise of the engine, i would agree that a v8 sounds very good when it is roaring. Valves are actually the openings for fuel to get into the cylinders and the exhaust to come out from. Most modern engines have two valves for incoming fuel and two valves for the exhaust making a total of four valves per cylinder. hope that clears it for you

- Q: I did a compression check on my 350 chevy. I have low compression of 175psi on one cylinder.The other seven cylinders range from 195psi to 205psi Could the valves be too tight on the cylinder with 175 psi compression?

- unless they have been tampered with that wouldn't be it,they usually wont tighten up on their own,i would suspect maybe a valve with a slight burn place on it that's causing that to happen or a ring causing you to loose that much compression,try adding a small amount of oil in the cylinder and then do the compression test again,that will tell you if its a ring or a valve,that's a big loss of compression ,and when you see that much of drop its usually a burnt valve.good luck.

Send your message to us

Butterfly Valve DN150 BS5163 Best Quality Commercial Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords