High Quality Flanged Wafer Type Butterfly Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Flanged Wafer Type Butterfly Valve

Product Information Of High Quality Flanged Wafer Type Butterfly Valve:

Butterfly valve is mainly consisted of body, stem, disc, seat and driver (lever, gearbox, pneumatic and electric Actuator) and so on. On off and controlling flow of valve are made by turning stem and disc together.

Size | DN40-DN1200 |

End flange | ANSI B 16.1, EN 1092, AS 2129 |

Face to face | ANSI B 16.10; EN 558-1 Series 20 |

Top flange | ISO 5211 |

Normal Pressure | DN40-DN600 PN1.0/1.6MPa (150/200PSI) DN700-DN1200 PN1.0MPa (150PSI) |

Body | CI/DI/WCB/ALB/CF8/CF8M |

Disc | DI/ALB/Rubber lined Disc/ 1.2501/CF8M/1.4529/CF8/Hastelloy Alloy/Monel |

Stem: | 416/304/316/431/17-4PH |

Seat | NR/Hypalon/EPDM/Neoprene/NBR/Wear-Resistant EPDM/Viton/Silicon/Heat-Resistant EPDM/White NBR/White EPDM/EPDM (NSF)/PTFE |

Suitable Temperature | -40c~80c |

Apply | Fresh water, sewage, sea water, air, vapor, food, medicine, oils, alkalis, salt etc. |

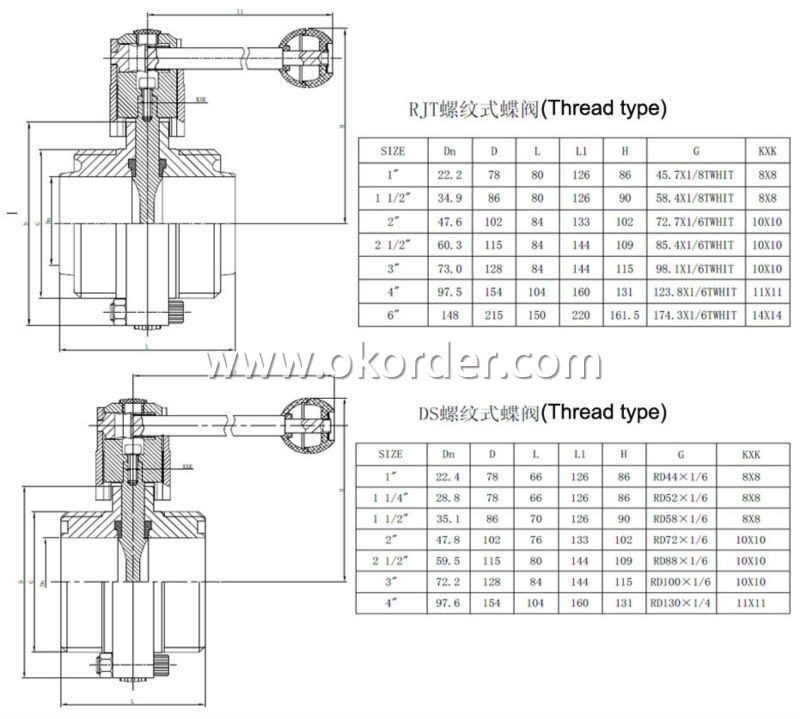

Drawing Example:

Specifications Of High Quality Flanged Wafer Type Butterfly Valve:

Nominal bore: 1-60"

Nominal pressure: ANSI150-300Lb

Connection type: flange type, clamp type

Temperature range: -20-600oC

Transmission type: worm, lever

Optional material: GGG500-7 , GG20 , WCB 304 316 316L

Packing: Wooden box

Features Of Double Flanged Butterfly Valve:

Body: cast iron, ductile iron

Metal seat and disc with EPDM O ring seal

Gear box operator

Features Of Wafer Butterfly Valve:

Size: 2" - 24"

Standard: ANSI, BS, DIN, JIS

Working pressure: PN16

Suitable media: water, oil and gas

This product adopts three-eccentric structure, has no friction between valve plate and valve seat, high flowrate and long service life and is able to increasingly tighten.

Product Advantages Of High Quality Flanged Wafer Type Butterfly Valve:

Small in size and light in weight and maintaince. It can be mounted wherever needed.

Simple, compact structure, quick 90 degree on-off operation.

Disc has two-way bearing, perfect seal, without leakage under the pressure test.

Flow curve tending to straight-line. Excellent regulation performance.

Various kinds of materials, applicable to different medium.

Strong wash and brush resistance and can fit to bad working condition.

Center plate structure, small torque of open and close.

Long service life. Standing the test of ten thousands opening and closing operation.

Can be used in cutting off and regulation medium

Production Flow Of High Quality Flanged Wafer Type Butterfly Valve:

Usage/Applications Of High Quality Flanged Wafer Type Butterfly Valve:

These products are widely used in water source projects, urban water supply and drainage, sewage treatment, electric power, petroleum, petrochemical, heat supply, shipbuilding, medicine and metallurgy industries.

Valves are used for regulating or cutting off liquids in pipelines. Liquids available include water, sewage, sea water, air, foodstuff and oil.

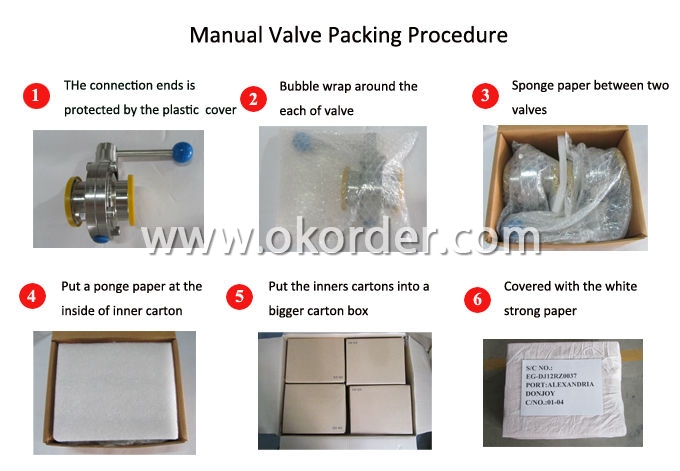

Packaging & Delivery Of High Quality Flanged Wafer Type Butterfly Valve:

- Q: What does "10" in the butterfly valve "D71X-10" mean?

- Represents the nominal pressure, refers to the 10MPa pressure butterfly valve, Zhengzhou butterfly valve factory specializing in the manufacture.

- Q: I want to switch off the water in the bathroom only due to replacing sink taps, will water still come out of the pipe if i turn the stop valve

- Water should be off to the sink is the stop valve off

- Q: Have an iron block, aluminum heads, solid roller lifters, Jessel rocker shafts, what should my valve clearances be cold, and hot??

- Only way to be sure is to put clay on top of a piston and turn the engine over by hand and then measure the clearance on the indentation in the clay.

- Q: I have a 1993 Oldsmobile Cutlass Supreme and I think I have the case of the blow-by. The engine had high mileage, but was rebuilt b/c it stalled while driving. 3.1L V6 gasoline engine. The fuel filter and the fuel pump are brand new. Now we have the same problem a few months later. It stalls while driving. Its been sitting a while and won't start by itself, so I pulled off the air intake hose off of the air filter to spray starting fluid into it. I noticed oil puddled in the air intake hose, so I looked for the PCV valve on the rocker cover. There is a tube going from the air-intake hose to the rocker cover. I popped out the tube from the rocker cover and there is no PCV valve. Just tube. Is that where the PCV valve is supposed to go? If not, where can I find it on the engine? And could that possibly fix the blow-by and the stalling engine? I'd appreciate any help. Thanks in advance.

- pcv valve is on the valve cover closest to the firewall.it is attached to a rubber hose that runs to the intake. right below an electrical plug

- Q: What is the effect of nylon coating on butterfly valve plate? Thank you

- Mainly media will not be contaminated by rust on the body, you should say that the central soft sealing butterfly valve, the central valve is generally cast steel or cast iron material, so useNylon coatingLining up. There are soft seals, sealing performance is relatively high

- Q: The difference between gate valve and butterfly valve, as well as cut-off valve, what are their applicable conditions? Advantages and disadvantages?

- Without strict conditions and advantages and disadvantages, of course, the equipment requires a relatively high degree of automatic control. I can check it out on Baidu.

- Q: I went online to check where was the pcv valve for a 2001 ford focus, but I didn't find it. Does anyone have a picture? Thanks

- The PCV (positive crankcase valve) is usually on top of the engine or in the valve cover, but it will be in different locations depending on the engine cylinder count: 4, 6, or 8 cylinder. You may have to go to a dealer and ask for a parts breakdown drawing which will show you where all the various parts are located. Some libraries have big books that show all the details about any model of car. Ask around.

- Q: What are the classification criteria for pneumatic butterfly valves?

- Pneumatic flange butterfly valve, pneumatic flange butterfly valve, this product is made up of rubber sealed butterfly valve and carbon steel or stainless steel valve plate and valve stem. Suitable temperature is less than or equal to 80 to 120 DEG C, such as food, chemical, petroleum, electric power, textile, papermaking, water supply and drainage, gas pipes to regulate the flow and closure of the role of media.Pneumatic control valve is a valve (valve plate) around the rotating fixed axis perpendicular to the channel, which is composed of double or single acting piston (spring reset type) pneumatic actuator and butterfly valve, a rotary type high performance adjust or cut off valves, electric, pneumatic valve positioner or electromagnetic valve, air filter regulator, limit switch (valve position), can be realized on the fluid medium in the pipeline and process to adjust the proportion of the two cut off control, automatic control to achieve the parameters of the fluid flow, pressure, temperature, liquid level etc..

- Q: Butterfly valve is generally used in what position?

- Butterfly valve used in furnace, coal gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, environmental protection, chemical smelting and power building water supply and drainage engineering system in conveying a variety of corrosive and non corrosive media pipeline, used to adjust and cut off the media flow.

- Q: butterfly valves d7a1x5

- D- valve type (butterfly valve), 7- connection mode (to clamp), A- valve shape mode (A), 1- structure form (vertical plate), X5- valve seat sealant species (Ding Qing, NBR)

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;North America;Asia;Africa |

| Company Certifications | ISO9001:2008 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 20-50 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 8,350 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Flanged Wafer Type Butterfly Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords