Hot Sell Butterfly Valve Concentric Rubber Wafer PTFE 360 Hard-Backed ISO 5211 Shaft Support

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

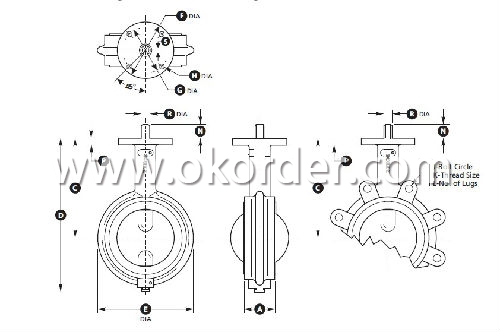

Description of Butterfly Valve

Concentric Butterfly Valve has a resilient rubber seat with a metal disc. This type of butterfly valves can be used for isolating or regulating flow.

Wafer, Lug or U type flanged body style fit between FF or RF flanges

PTFE bushing ensure the maximum shaft support and centralized alignment

360°polished disc assures positiveon-off

Hard-Backed Cartridge seat or Edge-Boot seat

The pin,spline or square connection are all available

Universal ISO 5211 mounting pad

Technical Data of Buttefly Valve

| Size | DN40-DN1200 |

| General Design | ISO 5752/BS 5155/API 609 |

| Mounting Pad | ISO 5211 |

| Face to Face | API 609/EN 558-1 20 series etc. |

| Flange Drilling | DIN 2501 PN10/16 |

| Inspection and Test | API 598 |

﹡For all available general design, face to face standard and flange drilling,please kindly contact CNBM directly.

Materials of Parts of Butterfly Valve

| Parts | Description | MaterialMaterial |

| 1 | Body | Cast Iron/Ductile Iron/WCB |

| 2 | Bushing | PTFE/Bronze |

| 3 | O-ring | EPDM/NBR |

| 4 | Shaft | Stainless Steel |

| 5 | Disc | Stainless Steel/Al-Bronze/Ductile Iron |

| 6 | Seat | EPDM/NBR/VITON/PTFE |

| 7 | Pin | Stainless Steel |

﹡For other material request,please kindly contact CNBM directly.

- Q:How do hydraulic butterfly valves work?

- Butterfly valve hydraulic drive device working principle1. manual operationWhen the hydraulic system suddenly fails, the valve can not move when the butterfly plate at any stop. Then, shaking the manual device, the guide block guide block in front of the manual shaft together with the driving shaft end, the cogging and drive shaft spline manual corresponding to the slot. Then, by dialing the driving device, the dial is shifted to the left end, and the transmission spline is connected with the manual shaft by a gear sleeve (the driving device is provided with a limit for preventing the tooth sleeve from jumping up), and the crank is disengaged from the hydraulic cylinder to disengage the hydraulic cylinder. Then turn the manual device and use the manual device to realize the disc movement.2. hydraulic operationWhen the hydraulic system returns to normal operation, the actuating device needs to be operated by hand. First, adjust the hydraulic cylinder to its initial state (0 digits) or at any position. Then manually adjust the opening of the disc to the position corresponding to the cylinder stroke (by observing whether the mark on the gear sleeve is in accordance with the mark on the crank, and judge the position of the disc and the cylinder). Then pull the gear sleeve and engage the spline on the crank by poking the driving device. Then fix the shift to prevent jumping. At this point, start the hydraulic system to restore fluid flow.

- Q:I am confused as to the answer of this question. Please help.Indicate the status of the mitral, tricuspid and semilunar valves (whether they are open or closd) during the various phases of the cardiac cycle. Discuss the pressure in each of the relevant chambers or blood vessels during the phases with reference to the opening or closing of the valves.

- A heartbeat is a two-part pumping action that takes about a second. As blood collects in the upper chambers (the right and left atria), the heart's natural pacemaker (the SA node) sends out an electrical signal that causes the atria to contract. This contraction pushes blood through the tricuspid and mitral valves into the resting lower chambers (the right and left ventricles). This part of the two-part pumping phase (the longer of the two) is called diastole. The second part of the pumping phase begins when the ventricles are full of blood. The electrical signals from the SA node travel along a pathway of cells to the ventricles, causing them to contract. This is called systole. As the tricuspid and mitral valves shut tight to prevent a back flow of blood, the pulmonary and aortic valves are pushed open. While blood is pushed from the right ventricle into the lungs to pick up oxygen, oxygen-rich blood flows from the left ventricle to the heart and other parts of the body. After blood moves into the pulmonary artery and the aorta, the ventricles relax, and the pulmonary and aortic valves close. The lower pressure in the ventricles causes the tricuspid and mitral valves to open, and the cycle begins again. This series of contractions is repeated over and over again, increasing during times of exertion and decreasing while you are at rest. The heart normally beats about 60 to 80 times a minute when you are at rest, but this can vary. As you get older, your resting heart rate rises. Also, it is usually lower in people who are physically fit.

- Q:Why use special flanges for butterfly valves?

- Butterfly valve to use special flange, butterfly valve itself is because of the structure of the decision, the butterfly valve to clip type connection, this pair of clamps is a special flange.Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.

- Q:does it come in when you go over a certain rpm or do the valves change depending on how far you depress the throtle?

- The variable is the valve timing. The spark plug fires a split second before the piston reaches the top of the stroke, to give the fuel a bit of time to burn. But, the faster the piston travels in the bore, that split second gets shorter shorter. So the engine computer changes when the spark plug fires when the valves close, to maximize the power from each ignition stroke.

- Q:What kind of butterfly valve is sd342x?

- Sd342x: two-way double eccentric soft sealing butterfly valveS: two way pressureD: butterfly valve3: turbine operation4: flange connection2: double eccentricX: rubber sealProbably the shape is not so good in appearance,Double eccentric mostly elastic sealThree eccentric is multi-layer sealHope to be of help to youOpened valve Co., Ltd. on the production of butterfly valve

- Q:What are the classification criteria for pneumatic butterfly valves?

- Pneumatic flange butterfly valve, pneumatic flange butterfly valve, this product is made up of rubber sealed butterfly valve and carbon steel or stainless steel valve plate and valve stem. Suitable temperature is less than or equal to 80 to 120 DEG C, such as food, chemical, petroleum, electric power, textile, papermaking, water supply and drainage, gas pipes to regulate the flow and closure of the role of media.Pneumatic control valve is a valve (valve plate) around the rotating fixed axis perpendicular to the channel, which is composed of double or single acting piston (spring reset type) pneumatic actuator and butterfly valve, a rotary type high performance adjust or cut off valves, electric, pneumatic valve positioner or electromagnetic valve, air filter regulator, limit switch (valve position), can be realized on the fluid medium in the pipeline and process to adjust the proportion of the two cut off control, automatic control to achieve the parameters of the fluid flow, pressure, temperature, liquid level etc..

- Q:Fire signal butterfly valve what role?

- Signal butterfly valve should be human action monitoring alarm, once closed, that is, to the system alarmYou ask the two time, I answer two times, you give two points

- Q:What's the difference between electric butterfly valve and electric two way valve?

- Below we will be specific to understand the electric two way valve and electric butterfly valve of the difference between.Distinguish one: product performance is different, the electric two way valve is for the central air-conditioning fan coil supporting products; and electric butterfly valve and electric control valve is the same species;Difference two: the product function is different, the electric two way valve is automatic adjustment; and the electric butterfly valve is a variety of adjustment methods.Difference three: product classification is different, the electric two way valve body activities are more piston style structure; and butterfly valve structure is diversified, such as sealed form can be divided into soft sealing and hard sealing type of two.

- Q:What's the size of the signal butterfly valve sleeve?

- The signal valve of the fire door (not in the signal valve shutter doors, fire signal valve use: top fire signal butterfly valve with the valve opening and closing signal device, when the valve is closed by 25% (open degree 4/1), the signal device output signal was mistakenly closed to the fire control center. Therefore, this butterfly valve is the best matching product of automatic fire sprinkler system.

- Q:What does "C" in D971F-16C DN450 RF mean for electric butterfly valves?

- C represents the valve body and the material is cast steel;D stands for butterfly valve; 9 stands for electric; 7 stands for clip type; 1 represents middle line butterfly valve; 16 stands for nominal pressure 1.6Mpa; RF stands for flange joint; in the form of protruding surface.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;North America;Asia;Africa |

| Company Certifications | ISO9001:2008 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 20-50 |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 8,350 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sell Butterfly Valve Concentric Rubber Wafer PTFE 360 Hard-Backed ISO 5211 Shaft Support

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords