Butterfly Valve DN250 BS5163 for Wholesales Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

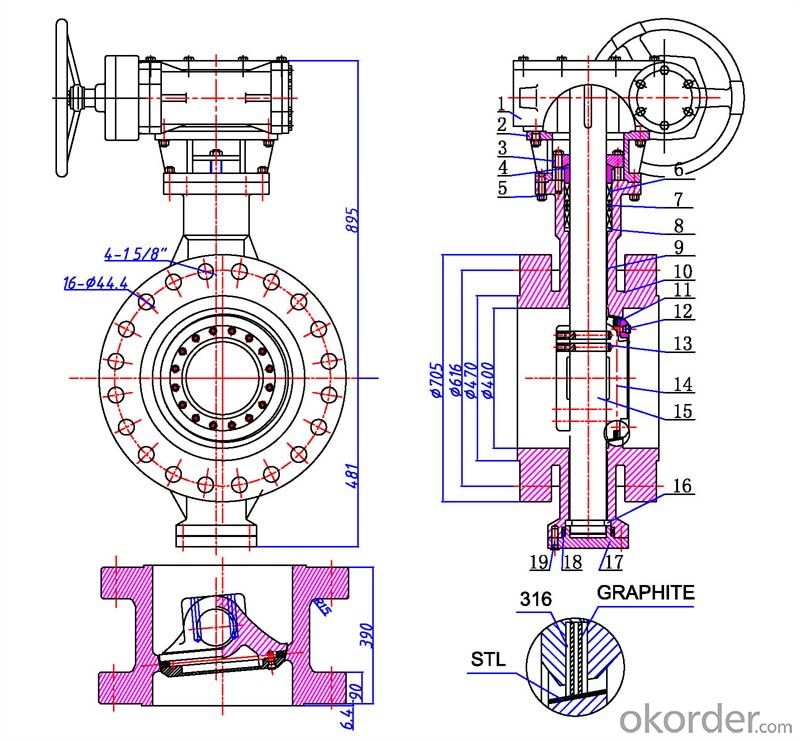

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What's the use of fire butterfly valve?

- Its working principle is as follows:1, the signal butterfly drive by the worm gear drive shaft and butterfly plate rotation, realize the opening and closing and control flow.2, rotating worm gear drive handwheel, so that the butterfly plate to open and close and adjust the flow of purpose, hand wheel clockwise rotation for the valve closed.3. The worm gear drive box is equipped with micro switches in two forms:A, in the gear box body is provided with open and close direction two microswitches, respectively, when the valve fully open and close action, connected to the control room "valve open" valve off "light source, to accurately display the switch state of the valve.B, the transmission device is arranged in the box body the microswitch (disc position close to 0 degrees), when the butterfly plate from 0 degrees to 40 degrees when the position of a micro switch, the output valve closed signal, 40 degrees to 90 degrees when the position of another pair of normally closed output valve opening signal. A cam that adjusts the touch microswitch and shows the different positions of the disc.The fire in the fire that is the switch signal butterfly valve in the pipe network, because the fire pipe water must be kept clear, so as to ensure the timeliness of fire, so the signal valve once closed, will tell the host signal module alarm, fire control network notify the monitoring center is closed.

- Q: i have a slightly small mitral valve leak in my heart. my cardiologist say nothing to worry about, but i am not sure. can some one explain if it would eventually lead to some complications?

- Mitral valve prolapse is the most common cardiac problem and may affect five to twenty percent of the population. The condition is most common in women, although men are also affected. With MVP, symptoms do not begin before the early teenage years (approximately age 14 in girls and 15 in boys), but adults of any age may be affected. MVP tends to run in families, so those with blood relatives with MVP have a greater chance of also having the condition. If a person has mild MVP, he/she needs no restriction of exercise. But if the MVP is big, then it is a different thing. Because, though complications in this condition are very less, people who suffer from this condition have to take extreme care. In case of large MVP, you may have to cut down on your physical activity, have a surgery and may be put you on medications like beta blockers. If the valve is truly defective (not just 'prolapsed'), it is serious. Unfortunately, doctors have mistaken a 'differently shaped' mitral valve as a disease in itself. And this is where the non-disease comes in. In simple terms, a mitral valve that appears prolapsed is usually normal. It still is not clear to experts why some mitral valves appear prolapsed and allow some blood leakage backwards. I have an answer for that phenomenon, but the important point is that the disease is a non-disease.

- Q: I want to switch off the water in the bathroom only due to replacing sink taps, will water still come out of the pipe if i turn the stop valve

- Water should be off to the sink is the stop valve off

- Q: How big is the butterfly valve with a diameter of 80?

- 80 caliber butterfly valveAskIn practice, this is not the case. Why not use it when I use it?. However, I used 65 butterfly valves, right? WhyChasing the answerWhat's the thickness of your pipe?

- Q: What's the difference between a clip type turbine butterfly valve and a flanged turbine butterfly valve?

- For clip butterfly valves, there are no flanges at the ends of the butterfly valve. There are only a few guide bolts. The valve is connected with the end flange with a set of bolts / nuts.In contrast, the demolition to facilitate some of the lower cost of the valve, but the drawback is that a sealing surface problems, the two sealing surfaces have to be taken apart.Flange butterfly valve at both ends of the flange, and pipe flange connection. The seal is relatively more reliable, but the valve is of relatively high cost.

- Q: Fire, the signal butterfly valve flange connection or welding?

- 1, do a good job with flange.2, flange (Flange), also known as flange, flange plate or edge. A flange is a part that is connected between the pipe and the pipe, used for the connection between the ends of the pipe. It is also used for the flange on the entrance and exit of the equipment. It is used for the connection between the two devices, such as the reducer flange. Flange connection or flange joint means that the flange, the shim and the bolt are mutually connected as a group of three detachable sealing structures. Pipe flanges are flanges used for piping in pipe installations. They are used on equipment and refer to the entrance and exit flanges of the equipment. The flange is lined with bolts to secure the two flanges. Gaskets for gaskets between flanges. Sub threaded flange connection (threaded connection), flange welding flange and flange clamp. Flanges are used in pairs. Low pressure pipes can be made of wire flanges and welded flanges with pressures of more than four kilograms. Add a gasket between the two flanges and secure with bolts. Different pressure flange thickness is different, they use the bolt is also different. Water pump and valve, and in the pipe connection, these equipment parts of the equipment also made corresponding flange shape, also known as flange connection. Any connecting parts that are bolted and closed in the vicinity of the two planes are generally referred to as flanges, such as the connections of the ventilation ducts, which can be called flanges". However, this connection is only part of a device, such as flanges and pumps connected, it is not good to call the water pump flange parts". Relatively small, such as valves, can be called flanges".3, also known as welding: welding, melt, is a kind of heating, high temperature or high pressure way of metal or other thermoplastic materials such as plastic manufacturing process and technology.

- Q: oil coming from valve into turbo charger

- it's located on pg 61222 of gm shop repair manual

- Q: Butterfly valves are widely used in 2.0MPa below the pressure and temperature of not more than 200 degrees of various media, right?

- First of all, is not the butterfly valve butterfly valve.Butterfly valve in the valve around the fixed axis rotating valve, called butterfly valve.1., as a sealed butterfly valve, it has been developed rapidly since the appearance of synthetic rubber, so it is a new type of shut-off valve. In our country until 1980s, the main role of butterfly valves in low-pressure valves, valve seat using synthetic rubber, by 90s, hard seal "metal seal" butterfly valve to rapid development. There are a number of valve factory can produce steady pressure metal seal butterfly valve, butterfly valve shall be shipped to a broader area.2. butterfly valves can transport and control the medium with water, condensed water, recycled water, sewage, sea water, air, gas, liquid gas, dry powder, mud, fruit pulp and a mixture of suspended solids.The domestic butterfly valve parameters are as follows:Nominal pressure: PN0.25 - 4.0MPaNominal diameter: DN100 - 3000mmWorking temperature: less than or equal to 425 DEG C

- Q: what are the step i need to do so i can change the valve seals my truck has been smoky.,,, any websites i want todo it myself... 1989 chevy silverado 2500 350 engine 5.7L

- First find out if that is the issue. Do a wet/dry compression on all the cylinders. That is where you do a compression test on all the cylinders and write them down. Then squirt about three pumps of oil from a oil can into each cylinder and retake the compressions. If the compressions don't change and are low, the valves are burnt and you need a valve job. If the compressions go way up after the oil seals the rings, then the piston rings are bad and the engine needs rebuilding and that may be where the oil smoke is coming from. If all the cylinders are within 20 psi and runs good, then it may be your valve guide seals are bad. You can replace them without pulling the heads. You can go to an auto parts store and buy a valve spring compressor that is used while the head is on the block. It has an air fitting that screws down into the spark plug hole and when filled with compressed air, holds the valves up while you remove the spring and replace the valve guide seal.

- Q: What is the difference between the installation and function of a butterfly valve and butterfly valve?

- The principle of the valve gate valve is open and close cases, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. Gate has two sealing surface, the most commonly used mode gate valve of the two sealing surface forming wedge, wedge angle with valve parameters vary, usually 50, medium temperature is not high when 2 degrees 52. Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce micro deformation of ram, in order to improve its process of deviation, make up the sealing surface angle in the process, the gate is called the flexible gate. Valve closed, the sealing surface can only rely on medium pressure to seal, that is to rely on medium pressure to the gate sealing surface pressure to the other side of the seat to ensure the sealing surface seal, which is self sealing. Most of the valve is forced seal, that is, when the valve closes, to rely on external force to force the gate to the seat, in order to ensure the sealing surface sealing. Gate valve with the stem along with a straight line of motion, called the lift rod gate valve is also known as the bar gate valve. Usually there is a trapezoidal thread on the lifter. The rotating motion is changed into a straight line through the nut at the top of the valve and the guide groove on the valve body. That is to say, the operating torque is changed into the operating thrust. When opening the valve, when the gate lift height is equal to 1:1 times of the valve path, the passage of the fluid is completely unblocked, but at run time, this position is unable to monitor. In actual use, the top of the stem is used as a sign, i.e., the open position, as its fully open position.Temperature changes appear to consider locking phenomenon, usually open to the vertex position, and then rewind 1/2 1 circle, as a fully open valve position.

Send your message to us

Butterfly Valve DN250 BS5163 for Wholesales Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches