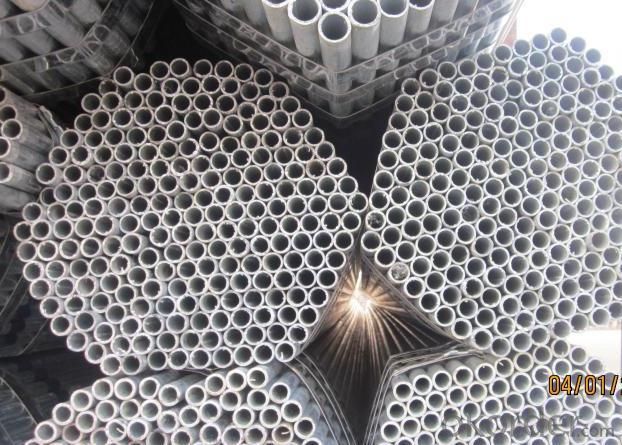

BS 1387 Hot Dipped Galvanized Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of BS 1387 Hot Dipped Galvanized Pipe:

Package:BS 1387 Hot dipped galvanized steel pipe in bundles acc to bs standard

Delivery:30-50days

Specification of BS 1387 Hot Dipped Galvanized Pipe:

| Thickness: | 0.7 - 8.18 mm | Section Shape: | Round | Outer Diameter: | 21 - 219 mm |

| Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

| Technique: | ERW | Certification: | BSI | Surface Treatment: | Galvanized |

| Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Non-alloy | Name: | BS 1387 Hot dipped galvanized steel pipe |

| Usage: | construction or water project,fence | C/O: | FORM E FORM A | Quality: | Prime Quality |

| Grade: | Q235,Q345,Q195-Q345 | Standard: | BS 1387,BS 1139,BS 4568,BS EN10219,JIS G3444-2006 |

Application of BS 1387 Hot Dipped Galvanized Pipe:

Widely used as the pipeline of industrial and civilian water, air, petroleum, natural gas, communication and so on.

- Q: What is the production process of seamless steel tube?

- The delivery status of hot-rolled seamless steel tubes is generally hot-rolled and delivered after heat treatment. Hot rolled seamless steel tube after quality inspection after staff strict hand picked in quality inspection should be carried out after the oil surface, followed by cold drawing experiments, hot rolling process should be carried out after the perforation experiment, if perforated expanding too large to carry out straightening correction. After straightening, the device is sent to the flaw detector by the transfer device to carry out the flaw detection experiment. Finally, the label is attached and the specifications are arranged and placed in the warehouse.

- Q: Can steel pipes be used for hydropower systems?

- Yes, steel pipes can be used for hydropower systems. Steel is a durable and strong material that can withstand high pressure and corrosion, making it suitable for carrying water or other fluids in hydropower systems. Additionally, steel pipes can be customized to different sizes and shapes, allowing for efficient water flow and distribution within the system.

- Q: Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are commonly used in steam distribution systems due to their high strength, durability, and resistance to high temperatures and pressure. They can effectively handle the transportation of steam in various industries such as power generation, chemical processing, and heating systems.

- Q: How are steel pipes tested for quality assurance?

- Steel pipes are tested for quality assurance through various methods including visual inspection, non-destructive testing (such as ultrasonic testing and magnetic particle inspection), mechanical testing (such as tensile strength and hardness testing), and dimensional checks. These tests help ensure that the pipes meet the required specifications, standards, and safety regulations, ensuring their durability, reliability, and performance in various applications.

- Q: How is the steel pipe dance installed at home?

- Perforated steel pipe, is very troublesome, need support to the roof and drilling in the room, the bottom with tripod frame fixed nail, and welding, installation is very troublesome;

- Q: How are steel pipes used in the construction of oil storage tanks?

- Steel pipes are commonly used in the construction of oil storage tanks as they provide strength, durability, and corrosion resistance. These pipes are used to connect various components of the tank, such as the walls, roof, and bottom, ensuring a secure and leak-proof structure. Additionally, steel pipes are also used to transport oil within the tank and for the installation of necessary fittings, valves, and other equipment.

- Q: What is the maximum pressure that steel pipes can withstand?

- The maximum pressure that steel pipes can withstand depends on various factors such as the grade and thickness of the steel, the diameter and length of the pipe, and the specific application. However, steel pipes are known for their high strength and durability, allowing them to withstand significant pressures ranging from several hundred to several thousand pounds per square inch (psi).

- Q: What are the different types of steel pipe fittings for chemical processing plants?

- There are various types of steel pipe fittings used in chemical processing plants, including but not limited to, elbows, tees, reducers, flanges, and couplings. These fittings are designed to connect and control the flow of fluids within the piping system, ensuring safe and efficient operation in industrial settings.

- Q: How can seamless steel tubes be produced?

- The material of rolling seamless tube is round tube blank, and the billet is processed by cutting machine to grow about 1 meters, and sent to the furnace by conveyor belt. The billets are heated into a furnace and the temperature is about 1200 degrees celsius. The fuel is hydrogen or acetylene. The temperature control in the furnace is a key problem. When the round billet is released, it should be punched through the pressure piercer. The most common punching machine is a cone roll piercer, which has high production efficiency, good product quality, large perforation and expanding diameter, and can be used in various steel grades. After the perforation, the round tube blank has been successively rolled, rolled or squeezed by three rollers.

- Q: How are steel pipes used in the construction of power plants?

- Steel pipes are used in the construction of power plants to transport various fluids, such as water, steam, and fuel, throughout the facility. They are essential for ensuring a reliable and efficient flow of these substances, which are crucial for the operation of power generation equipment. Additionally, steel pipes are also used for structural support and to create ventilation and exhaust systems within the power plant.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 1999 |

| Annual Output Value | Above Thirty Million RMB |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2011;CE:2010 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | Hui Ke Steel Pipe Co,.Ltd |

| Product Price Range | Average |

Send your message to us

BS 1387 Hot Dipped Galvanized Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords