Aluminum Coil 3003 H14 for Air Conditioning Condensers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Coil 3003 H14 for Air Conditioning Condensers

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

Grade: 3000 series

Alloy or not : Alloy

Thickness :0.15-3.0mm

Width:7.5-2000mm

Place of origin: Jiangsu province ,China mainland

Certificate: ISO9001:2008 ISO14001:2004 ,MSDS ,SGS ,Mill test ,GB/T3880-2006

Typical Chemistry:

Cu: 0.20

Si: 0.60

Fe: 0.70

Mn: 1.0/1.5

Zn: 0.10

Aluminum: Balance

Characteristics: The 3003 alloy is non-heat-treatable, its corrosion resistance and formability are excellent, but its anodizing characteristics are rated as fair.

Mechanical Properties:

Tensile Strength: 110-205

Yield Srength: 40-190

Elongation: 30-4

Brinell Hardness: 28-47

Typical Application:

3003 is often used in general sheet metal work, stamped, spun and drawn parts, cabinets, mail boxes, food and chemical storage and handling. If part is to be anodized consider 5005, if higher strength is desired consider 5052.

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

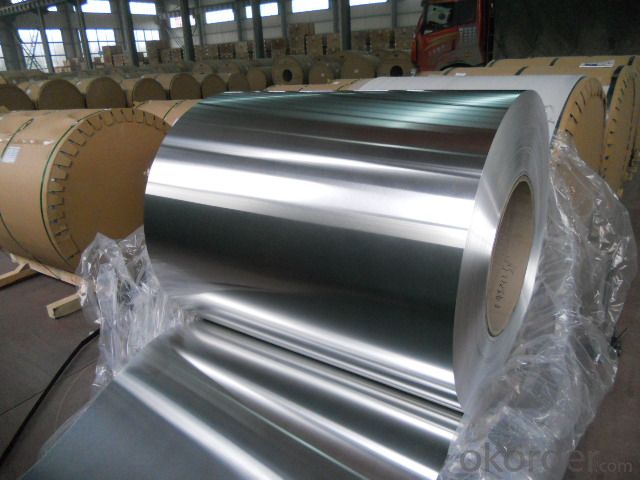

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:What are the different types of aluminum coils available in the market?

- In the market, one can find various types of aluminum coils, each possessing its own distinct characteristics and applications. 1. Basic Aluminum Coils: These coils are simple and commonly used for general purposes. They have a smooth surface and find applications in industries like construction, automotive, and packaging. 2. Aluminum Coils with Enhanced Aesthetic Appeal: These coils are coated with paint or other finishes to improve their visual appeal and provide extra protection against corrosion. They are widely used in the manufacturing of building facades, signage, and decorative items. 3. Textured Aluminum Coils: These coils have a textured or patterned surface, which gives them a decorative appearance and makes them slip-resistant. They are often utilized in applications where both aesthetics and functionality are important, such as flooring, staircases, and decorative panels. 4. Anodized Aluminum Coils: Through the anodizing process, a protective oxide layer is formed on the surface of these coils. This enhances their resistance to corrosion and makes them suitable for outdoor applications, including architectural elements, electronic components, and the aerospace industry. 5. Pre-painted Aluminum Coils: These coils come with a pre-applied paint coating, eliminating the need for additional painting or finishing. They are frequently used in industries that require high-quality, durable, and consistently colored products, such as automotive, appliances, and electronics. 6. Aluminum Coils for Heat Transfer: Specifically designed for heat transfer purposes in air conditioning and refrigeration systems, these coils have high thermal conductivity. They are often made from alloy grades that offer excellent corrosion resistance in harsh environments. Considering the specific requirements and intended use of the aluminum coil is crucial before making a purchase. This ensures that the appropriate coil type is selected for the desired application, optimizing performance and longevity.

- Q:Can aluminum coils be used in the production of aluminum doors?

- Aluminum doors can be produced using aluminum coils. Typically, aluminum coils serve as a raw material in the manufacturing process of aluminum doors. These coils are constructed from top-notch aluminum alloy and are available in varying thicknesses and widths. They can easily be molded into different shapes and sizes to fulfill the particular requirements of the doors. Furthermore, aluminum coils possess characteristics such as lightweightness, durability, and resistance to corrosion, making them an excellent option for door production. The coils are commonly subjected to various techniques like cutting, bending, and welding to fabricate the desired door components. All in all, aluminum coils offer numerous advantages in terms of versatility, strength, and aesthetics, which explains their popularity among aluminum door manufacturers.

- Q:How do aluminum coils contribute to the corrosion resistance of marine applications?

- The corrosion resistance of marine applications is greatly improved by aluminum coils, thanks to the unique properties and characteristics of aluminum as a material. To begin with, aluminum naturally forms an oxide layer on its surface when it comes into contact with air. This oxide layer is highly resistant to corrosion and acts as a protective barrier to prevent further oxidation and corrosion of the metal. This inherent property of aluminum makes it an excellent choice for marine applications, where constant exposure to saltwater and moisture can be extremely corrosive. In addition, aluminum coils can be alloyed with elements like magnesium and manganese to further enhance their corrosion resistance. These alloying elements not only strengthen the aluminum but also improve its resistance to pitting and crevice corrosion. Pitting corrosion occurs when localized damage exposes the underlying metal, while crevice corrosion occurs in areas with restricted oxygen flow, such as gaps or joints. By alloying aluminum, the coils become more resistant to these types of corrosion, making them highly suitable for marine environments. Furthermore, aluminum coils can be coated with protective finishes such as anodizing or painting, which provide an extra layer of defense against corrosion. Anodizing involves creating a thicker and more durable oxide layer on the aluminum surface, thereby increasing its resistance to corrosion. On the other hand, painting acts as a physical barrier that shields the coils from direct contact with corrosive elements present in the marine environment. In conclusion, aluminum coils contribute to the corrosion resistance of marine applications through the presence of a natural oxide layer, alloying with other elements, and the option of protective finishes. These characteristics ensure that aluminum coils are highly durable and capable of withstanding the challenging conditions encountered in marine environments, guaranteeing their longevity and reliability.

- Q:Are there any specific maintenance requirements for aluminum coils?

- Yes, aluminum coils require regular maintenance to ensure optimal performance and longevity. Some specific maintenance requirements for aluminum coils include cleaning them regularly with a mild detergent and water solution, removing any debris or dirt that may accumulate on the coils, inspecting for any signs of corrosion or damage, and ensuring proper airflow around the coils by keeping the surrounding area clear. Additionally, it is important to schedule professional maintenance and tune-ups to check for refrigerant leaks or any other issues that may affect the performance of the aluminum coils.

- Q:How are aluminum coils measured and specified?

- Aluminum coils are measured and specified based on several key factors. The first aspect is the thickness of the coil, which is typically measured in gauge or millimeters. The thickness determines the strength and durability of the coil, with thicker coils being more robust. Another important specification is the width of the coil, which is usually measured in inches or millimeters. The width determines the size and coverage area of the coil, with wider coils offering greater coverage. The length of the coil is also a crucial specification. It is typically measured in feet or meters and determines the amount of material available for a specific project. Longer coils are often preferred as they minimize the number of joints required during installation. Additionally, the alloy and temper of the aluminum used in the coil are specified. Different alloys have varying mechanical and chemical properties, making them suitable for different applications. The temper refers to the heat treatment process applied to the aluminum, affecting its hardness and flexibility. Coil weight is another important consideration. It is typically measured in pounds or kilograms and determines the handling and transportation requirements for the coil. Lastly, the surface finish of the coil is specified. Common finishes include mill finish, which is untreated, and coated finishes such as painted or anodized. The surface finish affects the appearance and corrosion resistance of the coil. Overall, the measurement and specification of aluminum coils involve factors like thickness, width, length, alloy, temper, weight, and surface finish. These specifications help ensure that the coils meet the desired requirements for various applications.

- Q:Can aluminum coils be used for nameplates and labels?

- Indeed, nameplates and labels can utilize aluminum coils. Aluminum, being a versatile material, presents numerous benefits in this regard. Notably, its lightweight nature coupled with its durability renders it suitable for diverse applications. Furthermore, aluminum boasts exceptional resistance to corrosion, making it an excellent choice for outdoor usage or environments with high humidity levels. Moreover, aluminum lends itself easily to stamping, embossing, or engraving, thereby facilitating the creation of intricate designs and detailed text. Additionally, it is feasible to apply coatings or anodize aluminum coils to augment their visual appeal or provide added protection. All in all, aluminum coils offer a dependable and cost-efficient solution for nameplates and labels.

- Q:What are the common surface treatments for aluminum coils in the construction industry?

- Aluminum coils are widely used in the construction industry due to their lightweight, durability, and corrosion resistance. To improve their performance and appearance, various surface treatments are applied. In the construction industry, there are several common surface treatments for aluminum coils: 1. Anodizing is a widely used method that involves creating an oxide layer on the aluminum surface. This process enhances corrosion resistance, improves weather resistance, and provides coloring options. 2. Powder coating is a popular technique where a dry powder is applied electrostatically and then cured under heat. This results in a durable, smooth, and attractive finish that is resistant to chipping, fading, and scratching. 3. PVDF coating is a high-performance option that offers excellent weather resistance and color retention. It is commonly used in architectural applications where long-term durability and aesthetic appeal are desired. 4. Paint coating, using liquid paint, provides a wide range of color options and finishes. These coatings offer good corrosion resistance and can be tailored to specific design requirements. 5. Brushed finish is achieved by brushing the aluminum surface, creating a textured appearance. This process can be done mechanically or chemically, enhancing the aesthetic appeal of the coils. 6. Laminating involves applying a layer of protective film or laminate to the aluminum coil. This safeguards the coil from scratches, stains, and other damage during handling, transportation, and installation. These surface treatments not only enhance the durability and performance of aluminum coils but also offer customization options. Architects and designers can achieve their desired aesthetics while ensuring long-lasting performance in construction applications.

- Q:Are aluminum coils suitable for automotive body panels?

- Yes, aluminum coils are suitable for automotive body panels.

- Q:How much of a difference does it make? I recently bought a 700 SPS tactical in 308. It has the Houge pillar bedding stock. I love the tacky feeling rubber outside, but noticed that the fore end of the stock flexes a bit (enough to touch the free floating barrel.) I was wondering if the aluminum bedding block version of the same stock (or any other aluminum bedding stock) will be better? I know they cost more, and the experts claim they're great, but will an amateur shooter notice the difference? I like to target shoot, typically around 200 yards. BTW, I was also considering the Bell and Carlson medalist.

- Vote for the Aluminum yet somewhat might like a silver lined one bless by using a Catholic priest that emits holy water. That way in case they are additionally a vampire you nailed them.

- Q:To put aluminum heads on my car do i have to add other things or basically can i just get them and put them on

- Aluminum heads will warp the first time the engine accidentally overheats. Why would you go with aluminum?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil 3003 H14 for Air Conditioning Condensers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords