All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the best practices for handling and storing aluminum coils?

The best practices for handling and storing aluminum coils include using proper lifting equipment to prevent damage, ensuring a clean and dry storage area, avoiding exposure to moisture and extreme temperatures, and implementing a system to organize and rotate the coils to prevent damage from prolonged storage. Regular inspections, maintenance, and following manufacturer guidelines are also crucial for safe handling and storage.

How do aluminum coil properties change with temperature fluctuations?

The properties of aluminum coil, such as its strength, conductivity, and coefficient of thermal expansion, can change with temperature fluctuations. As the temperature increases, the aluminum coil tends to expand, which can affect its dimensions and shape. Additionally, the thermal conductivity of aluminum increases with temperature, meaning it becomes more efficient at transferring heat. These changes in properties should be considered when designing and using aluminum coils in various applications.

How are aluminum coils used in the automotive heat exchangers?

Aluminum coils are used in automotive heat exchangers primarily due to their excellent thermal conductivity and lightweight properties. These coils are typically shaped into fins or tubes and then integrated into the heat exchanger system. The high thermal conductivity of aluminum allows for efficient transfer of heat between the coolant or refrigerant and the surrounding air. Additionally, the lightweight nature of aluminum helps to reduce the overall weight of the heat exchanger, contributing to improved fuel efficiency in vehicles.

Can aluminum coils be used in the production of aircraft components?

Yes, aluminum coils can be used in the production of aircraft components. Aluminum is widely used in the aviation industry due to its lightweight, high strength-to-weight ratio, and excellent corrosion resistance. It is commonly used for manufacturing various aircraft components such as fuselage panels, wings, and structural parts. The use of aluminum coils allows for efficient fabrication and forming processes, making it a preferred choice in aircraft manufacturing.

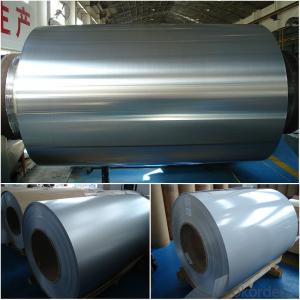

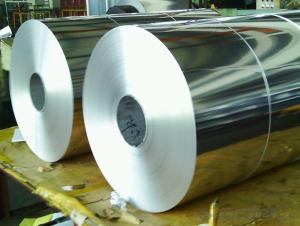

Wholesale Aluminum Coils from supplier in Eritrea

Whether you require Aluminum Coils for construction, manufacturing, or any other applications, we are committed to delivering high-quality products that meet your specific requirements. Our team of experienced professionals is dedicated to providing personalized service and ensuring customer satisfaction.

As a trusted supplier, we understand the importance of timely delivery and competitive pricing. We have established strong relationships with reliable manufacturers, allowing us to offer cost-effective solutions without compromising on quality. Our streamlined supply chain and efficient logistics network enable us to meet your demands promptly and efficiently.

In addition to our sales and quotation services, we also provide comprehensive technical support. Our knowledgeable experts are available to assist you with any technical queries, product selection, or application guidance. We strive to be your trusted partner throughout the entire purchasing process, from initial inquiry to after-sales support.

We take pride in our commitment to sustainability and environmental responsibility. Our Aluminum Coils products are manufactured using eco-friendly practices, ensuring minimal impact on the environment. We continuously strive to improve our processes and reduce waste, contributing to a greener future.

Partner with us for all your Aluminum Coils needs in the Eritrea market and experience the benefits of working with a trusted supplier. Contact us today for a personalized consultation and let us assist you in finding the perfect solution for your projects.

As a trusted supplier, we understand the importance of timely delivery and competitive pricing. We have established strong relationships with reliable manufacturers, allowing us to offer cost-effective solutions without compromising on quality. Our streamlined supply chain and efficient logistics network enable us to meet your demands promptly and efficiently.

In addition to our sales and quotation services, we also provide comprehensive technical support. Our knowledgeable experts are available to assist you with any technical queries, product selection, or application guidance. We strive to be your trusted partner throughout the entire purchasing process, from initial inquiry to after-sales support.

We take pride in our commitment to sustainability and environmental responsibility. Our Aluminum Coils products are manufactured using eco-friendly practices, ensuring minimal impact on the environment. We continuously strive to improve our processes and reduce waste, contributing to a greener future.

Partner with us for all your Aluminum Coils needs in the Eritrea market and experience the benefits of working with a trusted supplier. Contact us today for a personalized consultation and let us assist you in finding the perfect solution for your projects.