All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

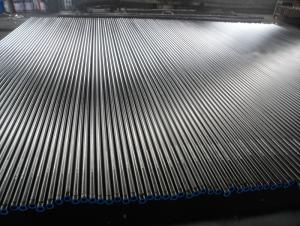

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of ultrasonic testing in detecting internal defects and imperfections in steel pipes?

The role of ultrasonic testing in detecting internal defects and imperfections in steel pipes is to use high-frequency sound waves to penetrate the material and create detailed images of the internal structure. By analyzing the reflections of these sound waves, ultrasonic testing can identify cracks, corrosion, and other flaws that may not be visible to the naked eye. This non-destructive testing method helps ensure the integrity and safety of steel pipes, allowing for timely maintenance and preventing potential failures.

How are steel pipes used in the creation of sculptures and public art installations?

Steel pipes are commonly used in the creation of sculptures and public art installations due to their strength, durability, and versatility. These pipes serve as the structural framework for the artwork, providing stability and support. Artists use various techniques to shape, bend, and weld the pipes, allowing for intricate and dynamic designs. Additionally, steel pipes can be painted or coated to enhance the aesthetic appeal of the sculpture or installation, making them a popular choice in the world of art.

What are the implications of water hammer in steel pipelines, and how can it be controlled?

Water hammer in steel pipelines can have several implications. Firstly, it can cause damage to the pipeline itself, leading to leaks or even bursts. This can result in costly repairs and potential downtime for the system. Additionally, water hammer can also cause damage to the fittings and valves in the pipeline, reducing their lifespan and effectiveness.

To control water hammer in steel pipelines, several measures can be taken. One common method is the installation of surge tanks or pressure relief valves, which help absorb and dissipate the excess pressure generated during water hammer events. Additionally, the use of air chambers or water cushions can also help mitigate the impact of water hammer by providing a cushioning effect.

Properly designed and installed check valves and control valves can also play a significant role in controlling water hammer. These valves can be set to close gradually, reducing the sudden changes in flow velocity that contribute to water hammer. Hydraulic shock absorbers, such as surge suppressors or dampeners, can also be installed to absorb and dampen the pressure waves caused by water hammer.

Regular maintenance and monitoring of the pipeline system is crucial to identify and address any potential issues that may lead to water hammer. This includes inspecting and repairing any damaged or worn-out components, ensuring proper valve operation, and implementing effective control strategies to minimize the occurrence and impact of water hammer events.

How are steel pipes used in the manufacturing of industrial equipment?

Steel pipes are commonly used in the manufacturing of industrial equipment due to their durability, strength, and versatility. These pipes serve various purposes such as transporting fluids, gases, and other materials within the equipment. They are also used for structural support, providing a solid framework for machinery and ensuring stability. Steel pipes can withstand high temperatures and pressures, making them suitable for applications in industries such as oil and gas, construction, and manufacturing.

Wholesale Steel Pipes from supplier in Eritrea

We are a Steel Pipes supplier serving the Eritrea, mainly engaged in the sale, quotation, and technical support services of various Steel Pipes products in the Eritrea region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Pipes procurement services in the Eritrea. Not only do we have a wide range of Steel Pipes products, but after years of market development in the Eritrea, we can also provide valuable experience for your projects.