All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How does the chemical composition of refractory materials affect their behavior?

The chemical composition of refractory materials greatly influences their behavior. Different chemical constituents can determine the material's thermal stability, resistance to heat, mechanical strength, and ability to withstand chemical reactions. For instance, high levels of alumina in refractory bricks enhance their resistance to high temperatures, while silica-based materials offer excellent thermal insulation. Additionally, the presence of certain elements can make refractory materials more resistant to corrosion or erosion caused by chemicals or molten metals. Overall, the chemical composition plays a crucial role in determining the performance and suitability of refractory materials in various industrial applications.

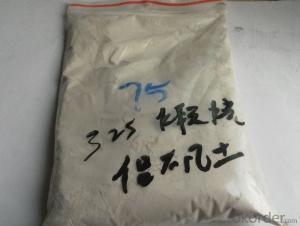

What is the importance of kaolin in refractory materials?

Kaolin is important in refractory materials because it acts as a crucial binding agent and filler. It enhances the strength and stability of refractory products, making them more resistant to high temperatures and thermal shocks. Additionally, kaolin's low shrinkage and high thermal conductivity properties contribute to the overall durability and performance of refractory materials.

How are raw materials tested for their suitability in refractory manufacturing?

Raw materials for refractory manufacturing are tested for their suitability through a series of tests that evaluate their physical, chemical, and thermal properties. These tests include evaluating the material's composition, particle size distribution, specific gravity, porosity, and thermal expansion. Additionally, the materials are subjected to various heating and cooling cycles to assess their resistance to high temperatures and thermal shock. The results of these tests help determine the raw materials' suitability for refractory manufacturing, ensuring that they possess the required characteristics to withstand extreme heat and harsh operating conditions.

Can you explain the role of mica in refractories?

Mica plays a crucial role in refractories as it acts as a thermal insulator and improves the heat resistance of the material. It helps to prevent the transfer of heat, reducing thermal conductivity and increasing the overall thermal efficiency of the refractory. Additionally, mica also provides mechanical strength and stability to the refractory, making it more resistant to physical stress and ensuring its durability in high-temperature environments.

Wholesale Raw Materials For Refractory from supplier in Eritrea

We are a Raw Materials For Refractory supplier serving the Eritrea, mainly engaged in the sale, quotation, and technical support services of various Raw Materials For Refractory products in the Eritrea region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Raw Materials For Refractory procurement services in the Eritrea. Not only do we have a wide range of Raw Materials For Refractory products, but after years of market development in the Eritrea, we can also provide valuable experience for your projects.

Hot Search

- Monolithic Refractories in Namibia

- Ceramic Fiber Products in Slovenia

- Refractory Bricks in Bahrain

- Raw Materials For Refractory in Peru

- Refractory Bricks in Kazakhstan

- Raw Materials For Refractory in Belarus

- Raw Materials For Refractory in Russia

- Ceramic Fiber Products in Monaco

- Refractory Bricks in Indonesia

- Refractory Bricks in Japan