All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the production process of electrolytic tinplate coil impact the environment?

The production process of electrolytic tinplate coil can have various impacts on the environment. Firstly, the extraction and processing of raw materials, such as tin and steel, can contribute to deforestation, habitat destruction, and increased carbon emissions. Additionally, the electrolytic tinplating process itself requires large amounts of energy and water, leading to increased greenhouse gas emissions and water pollution. Furthermore, the disposal of waste materials, such as tin sludge and spent electrolytes, can pose risks to soil and water quality if not properly managed. Therefore, the production process of electrolytic tinplate coil can have significant environmental implications, and it is important for manufacturers to adopt sustainable practices to minimize its negative impact.

What are the potential applications of electrolytic tinplate coil in the cosmetics industry?

Electrolytic tinplate coil can have several potential applications in the cosmetics industry. It can be used to manufacture packaging materials such as cans, tubes, and containers, providing a protective barrier against moisture, light, and air. Additionally, its corrosion resistance properties make it suitable for storing and preserving cosmetic products for longer periods. The tin coating on the coil also enhances the overall appearance and aesthetic appeal of the packaging, making it an attractive choice for high-end cosmetic brands.

Can electrolytic tinplate coil be used for packaging metal stamping products?

Yes, electrolytic tinplate coil can be used for packaging metal stamping products. It provides a protective and corrosion-resistant coating, making it suitable for preserving the quality and integrity of the stamped metal products during storage and transit.

Can electrolytic tinplate coil be used in the production of metal gift tins?

Yes, electrolytic tinplate coil can be used in the production of metal gift tins. Electrolytic tinplate coil is a type of steel coated with a thin layer of tin through an electrolysis process, which provides excellent corrosion resistance and aesthetic appeal. This makes it a suitable material for manufacturing metal gift tins, as it ensures the tinplate remains durable, visually appealing, and resistant to rust or oxidation.

How is the coil processed and formed into different shapes?

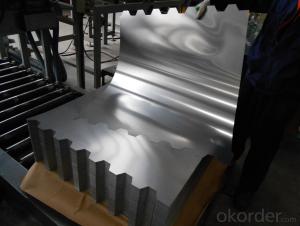

The coil is processed and formed into different shapes through a series of manufacturing processes. Firstly, the coil is uncoiled from its original spool and then straightened to remove any bends or imperfections. It is then fed into a machine, such as a roll forming or stamping machine, where it is shaped according to the desired design. This can be done by passing the coil through a series of rollers or by applying pressure through a die. The coil may also undergo additional processes like cutting, bending, or welding to achieve the desired shape. Overall, the coil is processed and formed into different shapes using various techniques and machinery to meet the specific requirements of the product being manufactured.

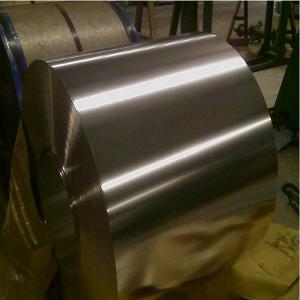

Wholesale Electrolytic Tinplate Coil from supplier in Eritrea

We are a Electrolytic Tinplate Coil supplier serving the Eritrea, mainly engaged in the sale, quotation, and technical support services of various Electrolytic Tinplate Coil products in the Eritrea region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Electrolytic Tinplate Coil procurement services in the Eritrea. Not only do we have a wide range of Electrolytic Tinplate Coil products, but after years of market development in the Eritrea, we can also provide valuable experience for your projects.