Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

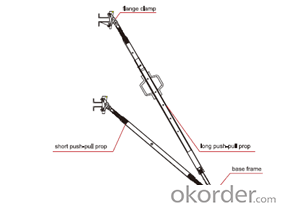

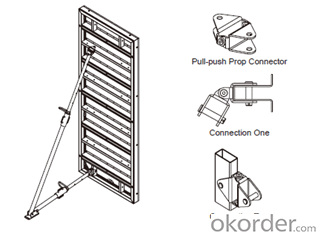

1. Structure of Push Pull Prop

Pull-push prop are used for supporting the wall and column formwork.

1.) For Timber Beam Formwork

2.) For Steel Frame Formwork

2. Main Features of Push Pull Prop

◆ High degree of standardization

◆ Simple site operations

◆ Quick adjustment

3. Push Pull Prop Images

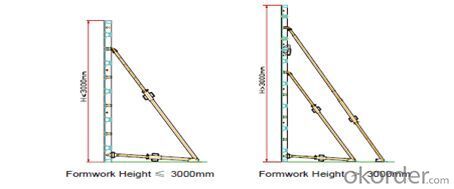

4. Single Side Bracket Specifications

There are three kinds of pull-push props, A,B,C. The A and B is suitable for the formwork not higher than 3000mm; C is suitable for the formwork higher than 3000mm as a reinforcer.

5. FAQ of Single Side Bracket

1) What can we do for you?

.We can ensure the quality of the push pull prop and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:How do steel props contribute to the stability of excavation sites?

- Steel props are essential for ensuring the stability of excavation sites. These props, also known as steel shoring, play a crucial role in supporting the sides of an excavation and preventing collapse or cave-ins. One key contribution of steel props is their ability to withstand the immense pressure exerted by the surrounding soil and prevent it from collapsing into the excavation. The props are usually installed vertically along the sides of the excavation, forming a secure barrier that holds the soil in place. This prevents the walls from caving in and provides a safe working environment for workers. Furthermore, steel props provide additional support to the excavation site by transferring the load from the soil to a more stable structure. By distributing the weight evenly, they reduce the risk of uneven settlement and subsidence, which can cause structural damage or even endanger the lives of workers. Another advantage of steel props is their adjustability. They can be easily extended or retracted to accommodate different excavation depths and allow for variations in ground conditions. This flexibility ensures that the excavation remains stable throughout the entire construction process, even as the depth of the excavation changes. Moreover, steel props are highly durable and resistant to corrosion and other environmental factors. This makes them suitable for long-term use in various excavation projects, providing reliable support and stability over extended periods. In summary, steel props contribute significantly to the stability of excavation sites by preventing soil collapse, transferring loads, and ensuring a safe working environment. Their versatility, adjustability, and durability make them an essential component in any excavation project, guaranteeing the safety of workers and the successful completion of the construction.

- Q:Can steel props be used for supporting temporary stages or podiums?

- Yes, steel props can be used for supporting temporary stages or podiums. Steel props are commonly used in construction to support heavy loads and provide temporary structural support. They are adjustable in height, making them suitable for various applications including supporting temporary stages or podiums. Steel props have a high load-bearing capacity and are designed to provide stability and safety. They can be easily installed and removed, making them a practical choice for temporary structures. Additionally, steel props can be adjusted to different heights, allowing for customization based on the specific requirements of the stage or podium. Overall, steel props are a reliable and effective solution for supporting temporary stages or podiums.

- Q:Are steel props suitable for supporting slabs or decks?

- Yes, steel props are suitable for supporting slabs or decks. Steel props, also known as adjustable steel props or scaffolding props, are commonly used in construction to provide temporary support for various structures, including slabs and decks. They are designed to be easily adjustable in height and provide stability and load-bearing capacity. Steel props are made of high-quality steel, which provides strength and durability. They can be used in a variety of applications, such as supporting concrete slabs during construction, providing temporary support during renovations or repairs, or supporting temporary decking for events or construction sites. Overall, steel props are a reliable and versatile solution for supporting slabs or decks.

- Q:Can steel props be used in construction of sports stadiums?

- Yes, steel props can be used in the construction of sports stadiums. Steel props are commonly used in construction projects to provide temporary support to structures. In the case of sports stadiums, steel props can be used to support large sections of the stadium during the construction process, such as the roof or upper levels. This allows for safe and efficient construction, ensuring the stability of the stadium as it is being built.

- Q:How do steel props contribute to the prevention of structural deformations?

- Steel props, also referred to as adjustable steel posts or shores, are of utmost importance in construction projects as they play a vital role in averting structural distortions. They contribute to the overall stability and safety of structures through the provision of temporary support during various construction stages. The primary manner in which steel props assist in the prevention of structural deformations is by shouldering the structure's load. During construction, steel props are strategically positioned to bear the weight of floors, walls, beams, or any other structural component that may be under construction or in need of reinforcement. By equally distributing the load, steel props assist in mitigating excessive stress on individual structural elements, thereby diminishing the risk of deformations. Moreover, the adjustability feature of steel props allows for precise positioning and alignment. This adaptability empowers construction workers to ensure that the structure remains level and plumb throughout the construction process. By preserving the correct alignment, steel props help forestall any tilting or leaning that could potentially lead to structural deformations. Another significant contribution of steel props is their capacity to absorb and distribute lateral forces. During construction, structures are subjected to diverse external forces, such as wind loads or seismic activity. Steel props assist in counterbalancing these lateral forces by providing supplementary support and stability. By resisting the lateral forces, steel props impede structural deformations, such as excessive sway or deflection. Additionally, steel props serve as temporary supports that aid in maintaining the integrity of the structure until permanent load-bearing elements, such as columns or beams, are installed. These temporary supports guarantee that the structure remains stable and secure during construction, thereby diminishing the risk of deformations or collapses. In conclusion, steel props contribute to the prevention of structural deformations by shouldering the structure's load, preserving proper alignment, absorbing and distributing lateral forces, and providing temporary support. Their role in construction projects is indispensable in ensuring the stability, safety, and longevity of structures.

- Q:How do you calculate the number of steel props required for a specific project?

- To calculate the number of steel props required for a specific project, you need to consider the weight and dimensions of the load being supported, the spacing between the props, and the maximum load capacity of each prop. By dividing the total weight of the load by the load capacity of a single prop and adjusting for the spacing, you can determine the number of props needed to ensure proper support and safety on the project.

- Q:What are the advantages of using a steel prop?

- Using a steel prop in construction projects offers numerous benefits. Firstly, steel props are renowned for their exceptional strength and durability. They have the ability to withstand heavy loads and provide reliable support for various structures. This strength ensures the safety of workers and the longevity of the project. Furthermore, steel props possess high adjustability and versatility. They can be easily extended or retracted to fit the required height, making them suitable for a wide range of applications. This flexibility allows for efficient and precise construction, as the props can be adjusted to meet specific project requirements. In addition, steel props offer excellent stability and load-bearing capacity. They provide a solid foundation for different types of structures, guaranteeing stability and preventing any potential collapse or accidents during construction. This stability is particularly crucial for projects involving heavy loads or unique architectural designs. Moreover, steel props are cost-effective. Their durability and reusable nature make them a cost-efficient option, as they can be utilized for multiple projects over an extended period. This reduces the need for frequent replacements or repairs, ultimately saving both time and money. Lastly, steel props are relatively easy to handle and install. They are lightweight and require minimal effort to set up and dismantle, streamlining the construction process and reducing labor costs. This ease of use makes steel props a popular choice among construction professionals. In conclusion, the utilization of steel props in construction projects provides advantages such as strength, adjustability, stability, cost-effectiveness, and ease of use. These qualities make them an excellent choice for ensuring safety, efficiency, and successful completion of various construction projects.

- Q:What are the alternatives to steel props for temporary support?

- There are various options available as alternatives to steel props for temporary support in construction projects. Some commonly used alternatives are as follows: 1. Adjustable Props: These props are similar to steel props but are constructed using materials like aluminum or lightweight alloys. They offer a temporary support system that can be easily adjusted to different heights. Adjustable props are lightweight, facilitating easy handling and transportation. 2. Timber Props: Timber props, also referred to as wooden props, are extensively utilized for temporary support in construction. They are made from solid wood or engineered timber and provide a cost-effective substitute for steel props. Timber props are lightweight, easy to install, and can be easily cut to the desired length. 3. Acrow Props: Acrow props are a popular choice as an alternative to steel props. They consist of an inner tube, an outer tube, a threaded rod, and a base plate. Made from high-quality steel, acrow props offer adjustable support. They find common application in construction projects where temporary support is required. 4. Scaffolding: Scaffolding systems can also be employed as an alternative to steel props for temporary support. They provide a versatile and secure working platform that can be easily adjusted to different heights. Scaffolding systems are constructed using various materials like aluminum, steel, or composite materials. 5. Shoring Systems: Shoring systems are specifically designed to offer temporary support to structures during construction or repair work. These systems comprise vertical supports, horizontal beams, and adjustable struts. Shoring systems are commonly utilized in building construction, excavation works, and tunnel construction. 6. Hydraulic Jacks: Hydraulic jacks present another alternative to steel props for temporary support. They utilize hydraulic pressure to provide support to structures. These jacks are commonly employed in applications where heavy loads need to be lifted or temporarily supported. When selecting an alternative to steel props for temporary support, it is crucial to consider the specific requirements of the project, such as load-bearing capacity, adjustability, ease of installation, and cost-effectiveness.

- Q:Can steel props be used for temporary support in wind tunnel construction?

- Yes, steel props can be used for temporary support in wind tunnel construction. Steel props provide strong and stable support, making them suitable for withstanding wind forces during the construction process.

- Q:What is the maximum lateral load that a steel prop can withstand?

- The maximum lateral load that a steel prop can withstand depends on various factors such as the specific type and size of the prop, its design and construction, as well as the conditions and environment in which it is being used. It is essential to refer to the manufacturer's specifications and guidelines for accurate information regarding the maximum lateral load capacity of a particular steel prop.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vertical Structure Support System for Push Pull Prop

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords