Prepainted Galvanized Rolled Steel Coil Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

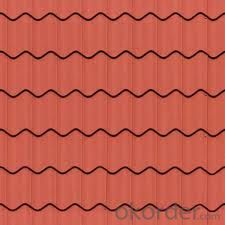

Prepainted Galvanized Steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

PrepaintedGalvanized Steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .For color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.Which is an ideal material;for manufacturing board.

Applications:

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Packaging & Delivery:

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images:

- Q:can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q:What are the different methods of oiling steel coils?

- There are several methods of oiling steel coils, including applying oil by roll coating, using a spray system, or immersing the coils in an oil bath.

- Q:What are the advantages of using galvanized steel coils?

- There are several advantages to using galvanized steel coils. Firstly, galvanized steel is highly resistant to corrosion, which means it can withstand exposure to moisture and other harsh environmental conditions without rusting. This makes it a durable and long-lasting material for various applications. Secondly, galvanized steel coils have a protective zinc coating that acts as a barrier against damage and provides excellent structural strength. Additionally, galvanized steel coils are versatile and can be easily formed, welded, and painted, making them suitable for a wide range of industries and projects.

- Q:I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Some types of stainless are magnetic and some are not. being magnetic isn't a reliable way to tell the difference. In fact, only the cheapest pots would be made out of grades of stainless that are magnetic. Stainless pots/pans are generally made of non-magnetic types, but then again, aluminum isn't magnetic either. Aluminum and stainless are superficially very similar.

- Q:How are steel coils cleaned before use?

- Steel coils are typically cleaned before use through a process called pickling, which involves immersing the coils in an acid solution to remove any scale, rust, or other impurities.

- Q:benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- well first of all u hav 2 get a mpR490 STEEL STOOLMADE

- Q:In the game RuneScape, the concept of the fictitious metal, Rune has intrigued me. On an equal area AND weight basis (with a possible 10 lb exception) what metal is 256% stronger than steel?

- Alumuniom so that, it is used in Rockets and planes another feature for Alumuniom, that it can bear a huge amount of heat.

- Q:What is the role of steel coils in the manufacturing of storage racks?

- The role of steel coils in the manufacturing of storage racks is to provide the raw material for the construction of the racks. Steel coils are used to create various components of the storage racks, such as the uprights, beams, and shelves. These coils are processed and shaped into the desired dimensions and configurations to ensure the strength, durability, and load-bearing capacity of the storage racks.

- Q:How is steel different than iron?How many different kinds of steel are there?What type is the strongest?Which type is the weakest?

- As first answer says, if you look at the number of commercial steel alloys available and consider that any given alloy can be heat treated to a wide range of physical properties, there are thousands and thousands of potential combinations. Technically, steel is an alloy of Fe and C but there are Fe-C alloys that are called cast irons, not steel, and... there are lots of alloy steels which have significant amounts of other elements added like Cr, Ni, Nb, V, Mo, etc. Fe alloys that have a lot of Cr and or Ni added are called stainless steels and there are dozens of them and many of them can be heat treated to produce a wide range of properties. As far as the strongest or the weakest, you have to get really specific about exactly what you mean because some steels are designed for room temperature properties, some are designed for elevated temperature properties, some for static loads, some for impact loads, some for wear resistance, etc, etc.. Steels make up the largest family of metal alloys (by weight and by volume) that humans use. There are a number of reasons for this but the big reasons include: 1) there is a LOT of iron on earth 2) it is relatively cheap to produce 3) you can easily change the physical properties over a every wide range. As an example... you can take a piece of steel that is so brittle it will shatter if you drop it on the floor and heat treat it so you can bend it like a pretzel without cracking and then heat treat it again to make it very strong and tough (resistant to fracture).

- Q:How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide a strong and durable core for the transformer. The coils are typically made of high-grade electrical steel, which has low electrical resistance and high magnetic permeability. These properties allow the coils to efficiently conduct and transform electrical energy, ensuring the proper functioning of the transformer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Galvanized Rolled Steel Coil Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords