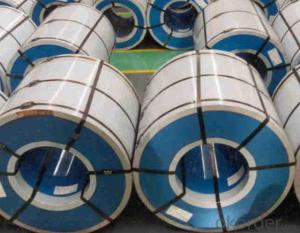

Wear resistant steel plate coil,/color steel coil/prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,GB,JIS | Grade: | DX51D | Thickness: | 0.13mm-0.8mm,0.13-0.7mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | CNBM | Model Number: | HUAYE224 |

| Type: | Steel Coil | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Constuction, Furniture, transport, electrical equipment,ect. | Special Use: | Wear Resistant Steel | Width: | 800mm-1250mm,1000mm, 1200mm,1250mm |

| Length: | As the width and thickness | Color: | Sea blue, white grey, crimson, green or as RAL | Zinc coating: | 40-100gsm |

| Coil Weight: | 3-6 Tons | Coil ID: | 508mm | Back coating thickness: | 5-7um |

| Top coating thickness: | 13-20um |

Packaging & Delivery

| Packaging Detail: | seaworthy expot package |

| Delivery Detail: | 15-20 days after receiving deposit by T/T |

Specifications

Wear resistant steel plate

1.Competitive price and High quality

2.Anti-corrosion

3.Width:800-1250mm

4.Thickness:0.13mm-0.7m

Business Products

Color coated galvanized steel coil (prepainted galvanized steel coil)

Shandong Huaye colour steel coil supplier

Wear resistant steel plate

PPGI sheet metal steel gauge

Galvanized steel coil (znc coating steel coil)

Galvalume steel coil (alu-zinc coating steel coil)

Cold rolled steel coil

Color coated galvanized steel coil

Characteristic

Thickness: 0.13mm-0.8mm

Width: 914mm-1250mm

Zinc coating: 40-150gsm

Color: Red, green, orange, white, blue, or as RAL code

Coating thickness: top: 13-20um; back: 5-7 um

Coil ID: 508mm10mm

Coil weight: 3-6 metric tons

Base material: Galvanized steel coil, galvalume steel coil, cold rolled coil, ect.

Packing: 4 eye bands and 4 circumferential bands in steel, galvanied metal fluted rings on inner and outer edges, galvanized

metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

Port of loading: Qingdao, Tianjin, Shanghai and so on

- Q:How are steel coils used in the manufacturing of heat shields?

- Steel coils are used in the manufacturing of heat shields to provide a durable and sturdy base material that can withstand high temperatures. The coils are formed into a specific shape and then coated with heat-resistant materials to create a protective barrier against heat and flames.

- Q:How would you calculate the maximum plastic deformation (expansion) a steel pipe can handle before it actually fails?

- You can calculate the maximum reversible strain, for elastic loading as follows: You need to look up the yield strength (for that particular type of steel). Divide this yield strength by the elastic modulus of steel (also called Young's modulus). That gives you the strain at the onset of yielding, the maximum you can strain the steel fibers before crossing the point of no return. If you are interested in the strain until failure, you need to take tensile test measurements. Seldom do people document an equation to model the non-elastic portion of the stress-strain curve of the specimen, because seldom do we design systems to operate with materials which yield. We want systems which only deform reversibly and elastically. This means you need to perform an experiment to find what you are actually desiring to know.

- Q:How are steel coils used in the production of metal ductwork?

- Steel coils are an essential component in the production of metal ductwork. These coils, typically made from high-quality steel, serve as the primary raw material for manufacturing ductwork. The process begins with the unwinding of the steel coil, which is then cut into specific lengths according to the required dimensions of the ductwork. These lengths are then shaped into the desired form using specialized machinery, such as roll formers or bending machines. The steel coils provide the necessary strength and durability to the ductwork, ensuring that it can withstand the pressure and environmental conditions it may encounter in its operational life. The coil's composition also allows for easy fabrication and customization, enabling manufacturers to create ductwork of various shapes and sizes to meet specific project requirements. Furthermore, the inherent properties of steel, such as its resistance to corrosion and fire, make it an ideal material for ductwork. Steel coils can be coated with protective layers, such as galvanized or stainless steel finishes, to enhance their longevity and performance. This added protection ensures that the ductwork remains intact and functional even in harsh environments or in the presence of corrosive substances. In summary, steel coils play a crucial role in the production of metal ductwork by providing the necessary raw material for fabrication. Their strength, durability, and customization capabilities make steel coils an indispensable component in the manufacturing process, resulting in reliable and long-lasting ductwork systems.

- Q:What are the major global steel coil markets?

- The major global steel coil markets are primarily concentrated in regions with significant industrial and manufacturing sectors. Some of the key markets include North America, Europe, and Asia-Pacific. North America, particularly the United States, is a major steel coil market due to its large automotive industry and construction sector. The demand for steel coil in this region is driven by the production of automobiles, infrastructure development, and residential construction. Europe is another significant market for steel coil, with countries like Germany, Italy, and France being major consumers. The automotive industry, construction sector, and machinery manufacturing contribute to the demand for steel coil in this region. Asia-Pacific, specifically China, is the largest market for steel coil globally. China's booming economy, rapid urbanization, and infrastructure development have led to a massive demand for steel coil. Other countries in the region, such as Japan, South Korea, and India, also have substantial steel coil markets due to their industrial and construction activities. Additionally, emerging markets in Latin America, the Middle East, and Africa are witnessing increasing demand for steel coil. These regions are experiencing economic growth and urbanization, leading to a rise in construction and infrastructure projects. Overall, the major global steel coil markets are driven by industrial and manufacturing activities, infrastructure development, and construction projects in various regions around the world.

- Q:This problem has puzzled me for a long time i always think about why stranded people on islands cant make a proper civilization and i always think it comes down to the ability to work metal. But its not like they could make a steel smelter/furnace out of sand...they would need an older one to use to make the new one...where the hell did the first one come from then????

- You don't need steel to make a smelter. Early ones were made of simple materials such as stone (though the first ones developed would be to smelt gold, then bronze, then iron-widespread use of steel is a relatively late innovation) A desert island resident however would be unlikely to have the skills, nor the iron ore to make one.

- Q:What are the different methods of pickling steel coils?

- There are several methods of pickling steel coils, including the use of acid pickling baths, electrolytic pickling, and pickle lines. Acid pickling baths involve immersing the steel coils in a bath of acid solution, such as hydrochloric or sulfuric acid, to remove scale and impurities from the surface. Electrolytic pickling uses an electric current to remove the scale from the steel coils, while pickle lines involve passing the coils through a series of acid baths and rinses to clean and prepare the surface for further processing.

- Q:How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings for various purposes, primarily for structural support. These coils are typically used to create steel frames, beams, and columns that provide strength and stability to the structure. Additionally, steel coils are also used in the production of roofing materials, wall cladding, and reinforcement bars, which further enhance the durability and safety of the building.

- Q:How are steel coils used in the automotive stamping industry?

- Steel coils are used in the automotive stamping industry to provide a continuous supply of flat steel sheets that are then fed into stamping machines. These coils are unrolled, straightened, and then fed through the stamping presses to create various automotive parts, such as body panels, chassis components, and other structural parts. The use of steel coils ensures efficiency, precision, and a consistent quality in the production of automotive parts.

- Q:Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q:A friends of mine says he has balls of steel and i told him i would melt em off with lava. He said it wouldnt work. i disagree

- some lava is hot enough to melt steel. Mostly, though, the metal would react with the lava and get eaten up that way rather than directly melting. Most lava can contain an awful lot of iron and other metals without any difficulty and are rarely saturated with those metals.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wear resistant steel plate coil,/color steel coil/prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords