Low Temperature Pressure Vessel Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

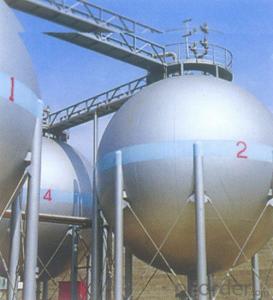

Low temperature pressure vessel (low temperature pressure vessel), is a kind of cryogenic vessel.

Summary

Design of temperature for pressure vessel -20 DEG C; the container is of low temperature pressure vessel for storage and transportation of liquefiedethylene and liquefied natural gas, liquid nitrogen and liquid hydrogen etc..The general pressure vessel commonly used ferritic steels in the temperaturedown to a temperature, the toughness of the steel will decrease sharply, and is very brittle, this temperature is usually referred to as the ductile brittle transition temperature. The use of pressure vessel in below the transition temperature conditions, due to defects, residual stress, stress concentrationand other factors caused by the high local stress such as the existence of a container, the container may be in no obvious plastic deformation under the condition of brittle rupture and disastrous accident. For low temperature pressure vessel must first select suitable materials, these materials should have good toughness at service temperature. The grain size of low alloy steelsavailable to -45 DEG C, 2.5% nickel steel available to -60 DEG C, 3.5% nickel steel available to -104 DEG C, available at -196 deg.c for 9% nickel steel.Below -196 DEG C when the selection of austenitic stainless steel andaluminum alloy etc.. In order to avoid local high stress in low temperaturepressure vessel, in the design of container should avoid excessiveconcentration of stress and additional stress; be strict inspection inmanufacturing the container, in order to prevent dangerous defects exist in the container. For because of the welding residual stress caused by excessive,should eliminate welding residual stress treatment after welding.

Performance characteristics

Cryogenic vessel performance and features of industrial [1] with liquid nitrogenat extremely low temperatures by nitrogen pressure variable is a colorless liquid, low temperature container at liquid nitrogen temperature is very low, and then use the cylinder holding, then put the cylinder in normal temperature, due to the environment temperature, temperature of liquid nitrogen is placed inside the bottle rises, also into the room temperature, then the liquid nitrogen in the bottle pressure will become higher.

But in the actual case, either the cylinder heat preservation effect is very good,or pressure safety valves, cylinders placed either opening time is very short.The cylinder temperature could not reach the normal temperature.

The industrial use of the liquid nitrogen at extremely low temperatures by nitrogen pressure variable is a colorless liquid, then the liquid nitrogentemperature is very low, and then use the cylinder holding, then put the cylinder in normal temperature, low temperature storage tank due to environmental temperature, then:

The bottle containing liquid nitrogen transformation could take place, i.e.vaporized, by liquid nitrogen into gaseous nitrogen, the cylinder pressure rise,this time the inside temperature or liquid nitrogen and nitrogen coexisttemperature is generally -196 degrees, absorb heat temperatures continue to rise, the pressure continues to rise, pressure safety valve will work, relief. If nopressure relief, only temperature, pressure of liquid nitrogen in the cylinder will be very high, resulting in high pressure vessel explosion.

Liquid nitrogen tank insulation effect is very good, the liquid nitrogen can bestored for 1 months does not vaporize finish inside.

- Q:What are the different methods of joining steel sheets?

- There are several methods of joining steel sheets, including welding, riveting, bolting, and adhesive bonding.

- Q:Can the steel sheets be easily formed into curves or angles?

- Yes, steel sheets can be easily formed into curves or angles using various techniques such as bending, rolling, or shaping.

- Q:Are steel sheets suitable for roofing systems?

- Yes, steel sheets are suitable for roofing systems. Steel is a durable and long-lasting material that offers excellent protection against the elements. It is resistant to fire, rot, and pests, making it a popular choice for roofs. Additionally, steel sheets are lightweight, easy to install, and require minimal maintenance, making them an ideal option for roofing systems.

- Q:How durable are steel sheets?

- Steel sheets are highly durable and known for their strength and resilience. They can withstand heavy loads, extreme temperatures, and harsh environmental conditions, making them ideal for various applications in construction, manufacturing, and automotive industries.

- Q:How do steel sheets handle weathering?

- Steel sheets handle weathering by forming a protective oxide layer on their surface when exposed to air and moisture. This oxide layer, known as patina, acts as a barrier against further corrosion, making steel sheets highly resistant to weathering effects such as rusting and degradation.

- Q:What is the average cost of steel sheets per square foot?

- The average cost of steel sheets per square foot can vary depending on factors such as thickness, quality, and market conditions. It is recommended to contact suppliers or conduct research to get the most accurate and up-to-date pricing information.

- Q:What is the difference between a perforated and woven steel sheet?

- A perforated steel sheet is a metal sheet that has holes or perforations evenly distributed across its surface. These holes can be of various shapes and sizes, such as round, square, or slotted. Perforated steel sheets are commonly used in applications where airflow, visibility, or drainage is required, such as in architectural design, filtration systems, and acoustic panels. The main advantage of perforated steel sheets is their ability to provide these functionalities while still maintaining structural integrity. On the other hand, a woven steel sheet is a metal sheet that is made by interlacing steel wires together in a specific pattern. This interlacing creates a mesh-like structure, where the wires form a series of intersecting horizontal and vertical lines. Woven steel sheets are commonly used in applications that require strength, durability, and security, such as in fencing, guarding, and industrial filtration systems. The main advantage of woven steel sheets is their ability to provide a high level of strength and security due to the tightly interwoven wires. In summary, the main difference between a perforated and woven steel sheet lies in their respective structures and functionalities. Perforated steel sheets have evenly distributed holes across their surface, providing benefits such as airflow and visibility. Woven steel sheets, on the other hand, are made by interlacing steel wires together to form a mesh-like structure, providing benefits such as strength and security. The choice between the two depends on the specific requirements of the application at hand.

- Q:Can the steel sheets be easily painted or coated?

- Yes, steel sheets can be easily painted or coated. The smooth surface of steel sheets allows for excellent adhesion of paint or other coatings. Prior to painting or coating, it is important to clean the surface thoroughly to remove any dirt, grease, or rust that may affect the adhesion. Additionally, applying a primer or a base coat can further enhance the durability and longevity of the paint or coating. Overall, steel sheets provide a suitable and easily paintable surface for a variety of applications.

- Q:Can steel sheets be used for bridge construction?

- Yes, steel sheets can be used for bridge construction. Steel is a widely used material in bridge construction due to its strength, durability, and ability to withstand heavy loads. Steel sheets are often used to create the structural framework of bridge beams and girders, providing the necessary support for the bridge's weight and traffic. Additionally, steel sheets offer flexibility in design, allowing for different shapes and sizes to meet specific bridge requirements. Overall, steel sheets are a popular choice in modern bridge construction due to their reliability and cost-effectiveness.

- Q:How do you transport steel sheets safely?

- To transport steel sheets safely, it is important to use proper equipment such as cranes, forklifts, or specialized trucks that are designed to handle heavy loads. The steel sheets should be securely strapped or clamped to prevent any movement during transportation. Additionally, using protective materials like padding or blankets can help prevent scratches or damage to the steel sheets. Regular inspections of the equipment and ensuring that the weight limits are not exceeded are also crucial for safe transportation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Temperature Pressure Vessel Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords