Bitumen Sheets Aluminum Backing for Aluminium Profiles to Make Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profiles to Make Windows and DoorsDescription:

Aluminium Profiles to Make Windows and Doors (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profiles to Make Windows and Doors:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

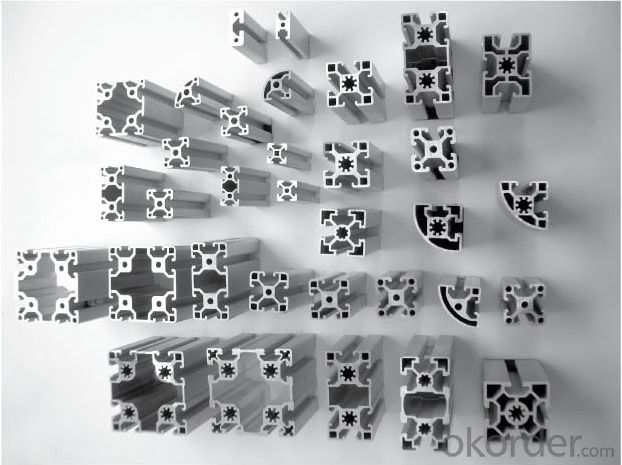

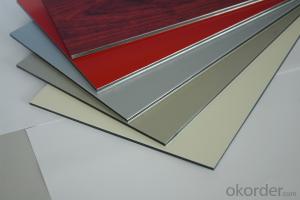

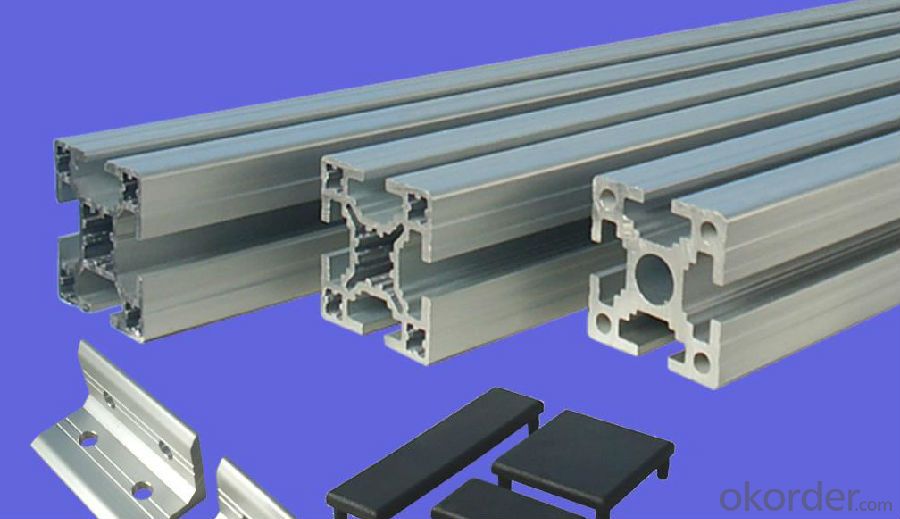

3.Aluminium Profiles to Make Windows and Doors Images:

4.Aluminium Profiles to Make Windows and DoorsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do you prevent warping of aluminum sheets during bending?

- One way to prevent warping of aluminum sheets during bending is by using proper techniques and tools. This includes using the correct bending radius, ensuring even distribution of pressure along the sheet, and employing a suitable clamping method to hold the sheet in place during the bending process. Additionally, preheating the aluminum sheet can help to reduce the likelihood of warping.

- Q: Can aluminum sheets be used for protective enclosures?

- Aluminum sheets have the ability to be utilized for protective enclosures. This material, known for its versatility and lightweight nature, offers exceptional durability and resistance to corrosion. It can easily be transformed into various shapes and sizes, making it suitable for constructing protective enclosures across a wide range of applications. Industries such as electronics, telecommunications, aerospace, and automotive commonly employ aluminum enclosures, which safeguard against environmental factors like moisture, dust, and electromagnetic interference. Moreover, these enclosures can be further improved with the addition of coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. All in all, aluminum sheets are a dependable option for protective enclosures due to their strength, adaptability, and capacity to endure challenging conditions.

- Q: How do you prevent warping of aluminum sheets during machining?

- One way to prevent warping of aluminum sheets during machining is by using proper coolant or lubricants during the machining process. This helps in reducing the friction and heat generated, which can cause warping. Additionally, maintaining correct cutting speeds and feeds, as well as ensuring proper tool selection and machining techniques, can also help minimize the chances of warping.

- Q: What are the various kinds of aluminum sheets utilized in the manufacturing of automobiles?

- <p>Aluminum sheets are widely used in automobile manufacturing due to their lightweight and strength. The different types include: 1. 5000 series aluminum sheets, known for their good formability and corrosion resistance, often used for body panels. 2. 6000 series aluminum sheets, which are strong and used for structural components. 3. 7000 series aluminum sheets, known for their high strength-to-weight ratio, used in safety-critical parts. 4. Aluminum alloy sheets, which combine the properties of aluminum with other elements for specific applications. 5. Aluminum clad sheets, which have a corrosion-resistant layer on the surface. These types are chosen based on the specific requirements of each automotive component.</p>

- Q: Are aluminum sheets suitable for industrial machinery?

- Yes, aluminum sheets are suitable for industrial machinery due to their high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. Additionally, aluminum is easy to fabricate, making it a popular choice for various applications in the industrial sector.

- Q: What is the final concentration of aluminum cation?

- You have to be able to determine the number of moles of Al+3 that each solution contributes to the final solution: 1. aluminum chloride: AlCl3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0431 L x 0.279 M = 0.0120 mol AlCl3 in solution When the AlCl3 in placed in the water, it dissociates to form the following ions: AlCl3 -- Al+3 + 3Cl- So for every one mole of AlCl3 placed in the water, one mole of aluminum ions will dissociate. Therefore, since we have 0.0120 mole of AlCl3 in the solution, that means that the aluminum chloride will contribute 0.0120 Al+3 ions to the final solution. 2. Aluminum sulfate: Al2(SO4)3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0146 L x 0.464 M = 0.00677 mol Al2(SO4)3 in solution When the Al2(SO4)3 in placed in the water, it dissociates to form the following ions: Al2(SO4)3 -- 2Al+3 + 3(SO4)-2 So for every one mole of Al2(SO4)3 placed in the water, two mole of aluminum ions will dissociate. Use the mole ratios of the dissociation reaction to determine the number of moles of Al+3 ions that the aluminum sulfate contributes to the solution. 0.00677 mol Al2(SO4)3 x (2 mol Al+3 ions / 1 mol Al2(SO4)3) = 0.01354 mol Al+3 ions Therefore, the total number of Al+3 ions in solution is the sum: 0.01354 + 0.0120 = 0.02554 mol Al+3 ions The last piece of information needed to determine the concentration of the final solution is the volume of the final solution. Since the two volumes were mixed, the volume of the final solution will be the sum of the two solutions. 0.0431 L + 0.0146 L = 0.0577 L Therefore, to calculate molarity: Molarity = moles of solute / liters of solution Molarity = 0.02554 mol / 0.0577 L = 0.443 M Al+3

- Q: Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets offer impressive fire-resistant qualities, making them an ideal choice for different applications that prioritize fire safety. The primary explanation for their fire resistance lies in the natural formation of a unique oxide layer on the aluminum's surface when exposed to oxygen. This layer acts as a protective barrier, preventing further oxidation and reducing the likelihood of combustion. Not only is the oxide layer on aluminum sheets highly stable, but it also boasts a high melting point. Consequently, it can endure high temperatures without melting or catching fire, rendering it flame-resistant. Additionally, the oxide layer acts as an effective thermal insulator, slowing down heat transfer and impeding the spread of fire. Another benefit of aluminum sheets is their low flammability. Aluminum is a non-combustible material, meaning it does not burn or support combustion. This characteristic proves especially advantageous in situations where fire containment and prevention are critical. Furthermore, aluminum sheets possess exceptional heat dissipation capabilities. They swiftly disperse heat away from the source, minimizing the risk of overheating and potential fire hazards. This makes them suitable for various heat-intensive applications, including electrical enclosures, automotive parts, and industrial machinery. In conclusion, aluminum sheets demonstrate remarkable fire-resistant qualities due to the protective oxide layer, non-combustible nature, and efficient heat dissipation. These attributes make them highly sought after for applications that prioritize fire safety, offering reassurance and safeguarding against potential fire incidents.

- Q: Can aluminum sheets be used for soundproofing?

- Indeed, soundproofing can be achieved using aluminum sheets. With its high density, aluminum serves as a formidable obstacle to the transmission of sound. By combining aluminum sheets with sound-absorbing materials like foam or fiberglass, the propagation of sound waves can be decreased, thereby mitigating noise pollution. Moreover, the versatility of aluminum sheets allows for effortless installation on walls, ceilings, and various surfaces, making it an ideal choice for soundproofing purposes.

- Q: What is the weight of aluminum sheets?

- The weight of aluminum sheets may differ based on the thickness and dimensions of the sheet. In general, thin sheets can weigh approximately 2.7 grams per square centimeter (g/cm^2), while thicker sheets can weigh around 6.9 g/cm^2. Nevertheless, it is crucial to acknowledge that these figures are approximate and may slightly fluctuate depending on the specific alloy and manufacturing technique employed. Consequently, it is advisable to seek precise weight specifications from the manufacturer or supplier when dealing with a specific aluminum sheet.

Send your message to us

Bitumen Sheets Aluminum Backing for Aluminium Profiles to Make Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords