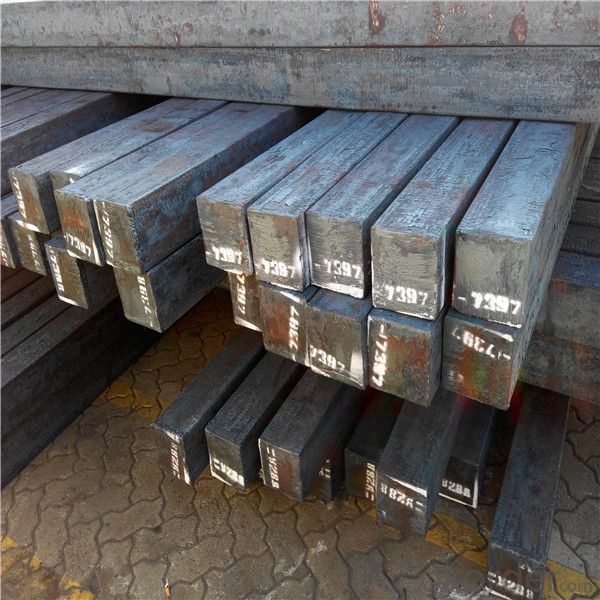

Billet steel from our own mill in good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15250 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base

building the support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: Are steel billets used in the production of electrical appliances?

- Steel billets are widely utilized in the production of electrical appliances. This versatile material possesses numerous benefits, including strength, durability, and corrosion resistance. Hence, it finds extensive application in manufacturing different components of electrical appliances, such as outer casings, frames, and internal structural supports. Steel billets serve as an intermediary product during the steel manufacturing process and can be further transformed into various shapes and sizes to cater to the specific demands of electrical appliance production.

- Q: What is the role of steel billets in the manufacturing of conveyor systems?

- Steel billets play a crucial role in the manufacturing of conveyor systems as they serve as the raw material for producing various components like rollers, frames, and support structures. These billets are heated, shaped, and machined to create the desired conveyor parts, ensuring strength, durability, and stability for the system.

- Q: How are steel billets used in the manufacturing of railway equipment?

- Steel billets are an essential component in the manufacturing of railway equipment. These billets, which are semi-finished steel products, are typically used as raw material for various railway components such as rails, wheels, axles, and other structural parts. To begin the manufacturing process, the steel billets are subjected to heating within a furnace to reach the desired temperature for hot rolling. This heating process helps to improve the malleability and ductility of the steel, making it easier to shape and form into the desired railway equipment components. Once the steel billets have reached the appropriate temperature, they are then passed through a series of rolling mills. During this stage, the billets are subjected to intense pressure, causing them to elongate and change their shape. This process is known as hot rolling and is crucial for transforming the steel billets into long, slender sections such as rails or axles. After hot rolling, the railway components are further processed to achieve the desired shape and specifications. For example, rails may undergo a process called head hardening to enhance their wear resistance and strength. Similarly, wheels and axles may undergo additional heat treatment processes to improve their mechanical properties and durability. It is important to note that the quality of the steel billets used in the manufacturing process plays a significant role in the overall quality of the railway equipment. The steel used should have specific characteristics such as high strength, toughness, and resistance to wear and fatigue, to ensure the safety and reliability of the final products. In summary, steel billets are an integral part of the manufacturing process for railway equipment. Through hot rolling and subsequent processing, these billets are transformed into various components that form the backbone of rail systems. The quality of the steel billets directly impacts the performance and longevity of the final railway equipment, making them a critical element in the industry.

- Q: What is the difference between continuous casting billet and cast billet?

- but with high-grade continuous casting line (full protection casting, electromagnetic stirring, liquid stopper control) compared both have a big difference in the crystal, oxidation, surface quality.

- Q: What are the main factors affecting the fatigue strength of steel billets?

- The main factors affecting the fatigue strength of steel billets include the material composition and quality, the presence of surface defects or imperfections, the applied stress levels, the frequency or rate of the applied cyclic loading, and the temperature conditions during the fatigue process.

- Q: How do steel billets contribute to the manufacturing of textile machinery?

- Steel billets play a crucial role in the manufacturing of textile machinery as they are used as raw materials for creating various components and parts. These billets are transformed into different shapes and sizes through processes like casting, forging, and machining to form the necessary components of textile machinery such as gears, shafts, frames, and bearings. The high strength and durability of steel billets ensure that the textile machinery is capable of withstanding heavy loads, high speeds, and continuous operation, resulting in efficient and reliable performance in the textile industry.

- Q: How do steel billet prices fluctuate in the market?

- Steel billet prices fluctuate in the market due to a variety of factors. One of the key factors is the demand and supply dynamics of the steel industry. When there is high demand for steel billets, prices tend to rise as suppliers have more leverage to set higher prices. Conversely, when demand is low, prices may decrease as suppliers compete for a smaller pool of buyers. Another important factor influencing steel billet prices is the cost of raw materials. Steel is primarily made from iron ore, coal, and scrap metal, and any fluctuations in the prices of these raw materials can directly impact the cost of producing steel billets. For example, if there is a shortage of iron ore, the price of steel billets may increase due to higher production costs. Additionally, market conditions and economic factors can also affect steel billet prices. Factors such as inflation, interest rates, and currency exchange rates can impact the overall cost of production and transportation, which in turn may influence the prices of steel billets. Furthermore, geopolitical events and trade policies can also play a role in price fluctuations. Tariffs, trade disputes, or changes in import/export regulations can disrupt the supply chain and impact the prices of steel billets. Overall, steel billet prices are subject to a complex interplay of factors, including demand and supply dynamics, raw material costs, market conditions, and geopolitical events. Traders, manufacturers, and investors closely monitor these factors to anticipate and respond to price fluctuations in the steel billet market.

- Q: How are steel billets used in the manufacturing of machinery?

- Steel billets are an essential component in the manufacturing of machinery due to their versatility and strength. These cylindrical metal bars, typically made from carbon or alloy steel, serve as the raw material that is transformed into various machine parts and components. One common application of steel billets in machinery manufacturing is for the production of machine frames and structures. The billets are heated and then hot-rolled or forged into the desired shape, ensuring the final product has the necessary strength and durability to withstand the mechanical stresses it will encounter during operation. Additionally, steel billets are used to create machine components such as gears, shafts, and axles. These parts require high tensile strength and resistance to wear and deformation, making steel billets the ideal material choice. The billets are typically machined or forged into the desired shape, ensuring precise dimensions and tolerances are met. Furthermore, steel billets can also be used in the manufacturing of machine tools, which are crucial for shaping and machining various materials. By using steel billets as the base material, machine tools can effectively handle heavy loads, provide stability, and ensure precision in the manufacturing processes. In summary, steel billets are integral to the manufacturing of machinery, as they provide the necessary strength, durability, and versatility required for the production of machine frames, components, and tools. Their ability to be shaped, machined, and forged into various forms allows for the creation of high-quality machinery that can effectively perform its intended functions.

- Q: What is the role of steel billets in the manufacturing of storage systems?

- Steel billets play a crucial role in the manufacturing of storage systems due to their unique properties and versatility. These billets are essentially semi-finished steel products that are used as raw materials in various manufacturing processes. The primary role of steel billets in the manufacturing of storage systems is to serve as the base material for fabricating different components, such as shelves, frames, supports, and racks. The high strength and durability of steel make it an ideal choice for these applications, as it can withstand heavy loads and provide long-lasting performance. Steel billets are typically melted and cast into specific shapes, such as square or round, to suit the requirements of the storage system design. These billets undergo further processing, such as hot rolling, to transform them into the desired dimensions and form. This process helps to refine the steel's microstructure, enhancing its mechanical properties and ensuring consistent quality. The versatility of steel billets allows manufacturers to customize storage systems according to specific needs. By shaping and welding steel billets, manufacturers can create storage systems with different configurations, sizes, and load capacities. This flexibility enables the production of storage systems that are tailored to meet various industrial and commercial applications, ranging from warehouses to retail stores. Moreover, steel billets offer excellent resistance to corrosion, making them suitable for storage systems used in both indoor and outdoor environments. This resistance ensures that the storage systems maintain their structural integrity and aesthetics over time, even in harsh conditions. In summary, steel billets play a vital role in the manufacturing of storage systems by serving as the raw material for various components. Their strength, durability, versatility, and corrosion resistance make them an ideal choice for fabricating storage systems that can withstand heavy loads, provide long-lasting performance, and meet specific design requirements.

- Q: What are the main factors affecting the formability of steel billets?

- There are several factors that affect the formability of steel billets, including the composition of the steel, its microstructure, temperature, and strain rate. The composition of the steel is a crucial factor in determining its formability. Elements such as carbon, manganese, and silicon can influence the strength and ductility of the steel. Higher levels of carbon and alloying elements can increase the strength of the steel but may decrease its formability. On the other hand, lower carbon content and higher levels of elements like manganese can enhance the formability of the steel. The microstructure of the steel is another significant factor. The size, distribution, and morphology of the grains in the steel can impact its formability. Finer grains generally provide better formability, as they allow for more uniform deformation during shaping processes. Additionally, the presence of precipitates or inclusions in the microstructure can affect the formability by causing localized stress concentrations. Temperature plays a vital role in the formability of steel billets. Heating the steel to elevated temperatures can increase its ductility and reduce its strength, making it easier to form. This process, known as hot forming, allows for greater deformation without the risk of fracture. However, excessively high temperatures can also lead to excessive grain growth, which can negatively impact formability. Lastly, the strain rate, or the rate at which the steel is deformed, can affect its formability. Higher strain rates generally result in reduced formability as they can lead to strain hardening, where the steel becomes harder and more resistant to deformation. Therefore, controlling the strain rate during forming processes is essential to maintain optimal formability. In conclusion, the main factors affecting the formability of steel billets include composition, microstructure, temperature, and strain rate. By considering these factors, manufacturers can optimize the formability of steel billets to meet specific requirements during shaping processes.

Send your message to us

Billet steel from our own mill in good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15250 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords