Bearing Four Row Cylindrical Roller Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

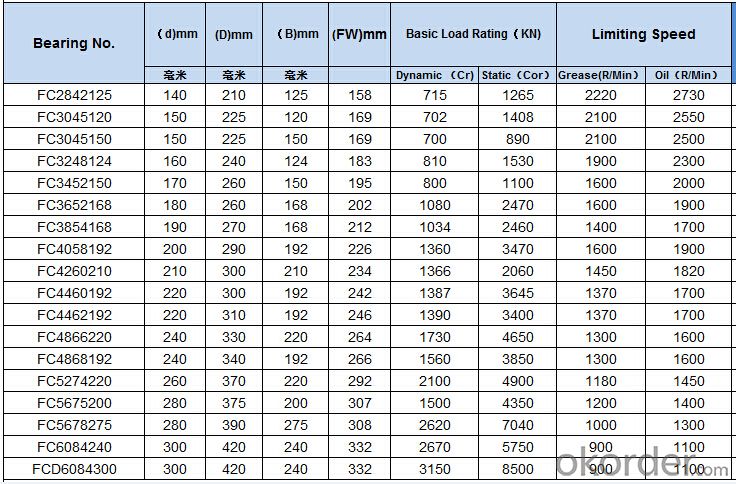

Four Row Cylindrical Roller Bearing

| Name | Four Row cylindrical roller bearing | ||||||||||||

| Type | Roller | ||||||||||||

| Materials | GCr15 | ||||||||||||

| cage's material | Steel,Brass | ||||||||||||

| Place of original | Shandong,China(Mainland) | ||||||||||||

| Seals type | Open,Sealed | ||||||||||||

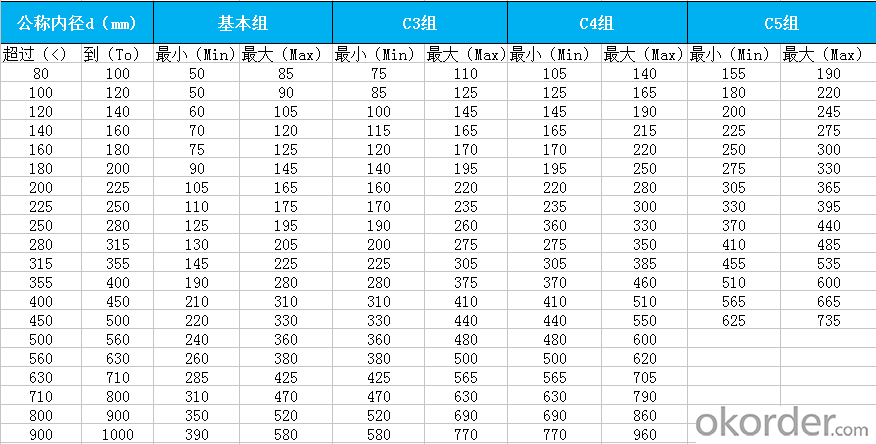

| Clearance | C0,C1,C2,C3,C4,C5,C6 | ||||||||||||

| Precision | P0-P6 | ||||||||||||

| Feature | This is consisted of an inner and other ring with a cage containing a complement of precision balls. | ||||||||||||

| Main application | Automobile,electrical equipment,instruments,agriculture machinery and many kinds of special machinery. | ||||||||||||

| Brand | OEM,ODM | ||||||||||||

| Market | America,Middle East,Southeast Asia,Brazil | ||||||||||||

| Quality level | AA+,A,B,C | ||||||||||||

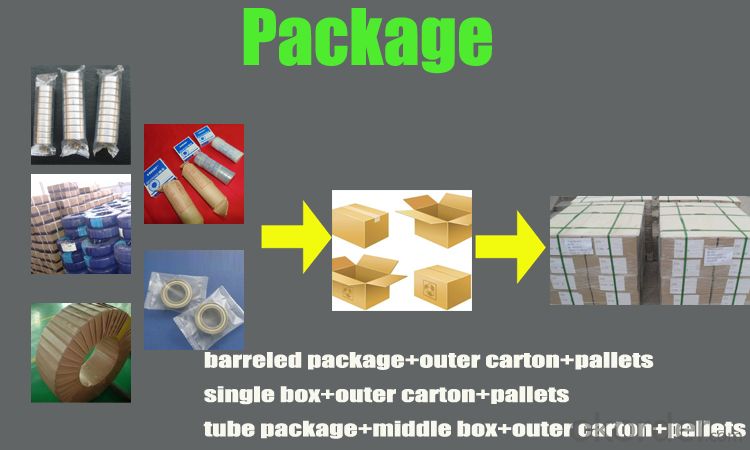

| Package | 1,barreled package+outer carton+pallets | ||||||||||||

| 2,single box+outer carton+pallets | |||||||||||||

| 3,tube package+middle box+outer carton+pallets | |||||||||||||

| 4,According to your requirement | |||||||||||||

| MOQ | 10PCS | ||||||||||||

| Port | Qingdao | ||||||||||||

| Payment Terms | T/T,PAYPAL,WESTERN UNION | ||||||||||||

| Delivery time | 5-25days,According to QTY | ||||||||||||

Features

1.) Offers a complete range, both metric and inch sizes available in metric and

imperial bore sizes ranging from 12 to 1320 mm.

2.)High radial load capacity - making cylindrical roller bearings suitable for high

speed applications.

3.)Designs - designated NU, NJ, NUP, N or NF for single row bearings and NNU or

NN for double row types, defines the bearing ring rib configuration.

4.) Cages - Available with pressed steel, machined brass and polyamide cages

throughout the range.

5.) Special designs - manufactures a range of four-row cylindrical roller bearings,

primarily designed for use as steel mill roll-neck bearings.

6.)Bearings are also available with both lubrication holes and a machined

lubrication groove on the outside surface of the outer ring.

Package

Factory

- Q: Which column roller bearing brand is good?

- Foreign SKF is better, the domestic is Kazakhstan axis, and then is Taiwan's Rui Rui, you can look at yourself, they recently in the Qingdao market to great influence, you can understand.

- Q: How to check the thrust cylindrical roller bearings?

- Bearing dimensions (or bearing samples) have "basic rated load (KN)", this column can be directly detected, in general, according to the use of appropriate multiplied by a (1.2~1.5) safety factor. In accordance with the requirements of the design manual, the equivalent load can be calculated (considering the speed, temperature, load and stability).

- Q: Attention problems of cylindrical roller bearings

- 1. The installation of bearings must be carried out in a dry, clean environment. Before installation, the machined surface of the shaft and shell, the shoulder end, the groove and the joint surface shall be carefully inspected. All mating surfaces must be carefully cleaned and removed, and the cast surface must be clean. 2, before the installation of bearings, should be cleaned with gasoline or kerosene, dry after use, and ensure good lubrication, bearings generally grease lubrication, oil lubrication can also be used. Grease lubrication, grease, anti rust, extreme pressure and other excellent greases should be used. Grease filling capacity for bearings and bearing box volume of 30%-60%, should not be too much. Double row tapered roller bearing and water pump shaft bearing with sealing structure have been filled with grease, which can be used directly by users and can not be cleaned again. 3, bearing installation, must be applied equally in the circumference of ferrule end face pressure to press into the ring, and may not directly tap bearing end face to the top tool, so as not to damage the bearing. Small amount of interference in the case, at room temperature can be used to suppress sleeve bearing ring face, beating with a hammer sleeve, the sleeve will be pressed into the ring balance. If installed in large quantities, use hydraulic press. When pressing, the outer end surface of the outer ring and the outer shoulder of the shell face shall be ensured, and the inner ring end face is tightly pressed with the shoulder end of the shaft platform, and no gap is allowed.

- Q: What is the maximum rotational speed of a single row full cylindrical roller bearing?

- FAG full cylindrical roller bearings are especially suitable for ultra high load and medium speed applications. Sealed single row and double row bearings are mainly used in transmission mechanisms, while sealed double row bearings are more suitable for lifting mechanisms. Single row full roller cylindrical roller bearings, in addition to the NJ23VH series, can not be separated. The two rings of the separable bearing can be tightly matched so that it is easy to install and disassemble.

- Q: Cylindrical roller bearings NUP2311E mounting dimensions: Da (max): 69Da (min): 64DB (min): 72DC (min): 80Da (max): 111What are the specific meanings of these dimensions? Thank you, master

- I don't know what you mean. The size of NUP2311E is: inside diameter, 55mm, outside diameter, 120mm height: 43

- Q: Why does cylindrical roller bearings fail abnormally?

- Generally, the causes of abnormal failure of cylindrical roller bearings are as follows:1, cylindrical roller bearing manufacturing accuracy is poor, one end of the bearings with loose, and travel source is larger, bearing frame rigidity is poor. Or the bottom of the bearing seat is uneven.2, cylindrical roller bearings axis misalignment (misalignment) axis and the housing of the shoulder to the surface is not vertical, shell installation, bearing two or more holes, different axis.

- Q: What are full cylindrical roller bearings?

- Full cylindrical roller bearingCommon cylindrical roller bearings1, single row full cylindrical roller bearingsNCFNJG2 、 double row full cylindrical roller bearingNNCLNNCFNNCNNFTwo, not common full cylindrical roller bearings1, full spherical cylindrical roller bearings2, CARB ring roller bearings

- Q: Is the roller bearing and the bearing chamber movable in the tapered rotor motor?

- E in cylindrical roller bearing is the meaning of improving internal cage design, similar to the SKF cylindrical roller bearing EC form, this type of bearing than without E, is to strengthen the design, the roller is filled more larger to increase the load. From the load point of view, it is better to choose E.

- Q: What are the components of cylindrical roller bearings?

- Cylindrical roller bearings are usually guided by two blocks of a bearing ring. The cage, roller, and guide ring form a composite, generally separable bearing.

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Because double row cylindrical roller bearings with high carrying capacity, high precision, separation, easy installation and disassembly, mainly used in lathes, milling machines, machining centers and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Bearing Four Row Cylindrical Roller Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords