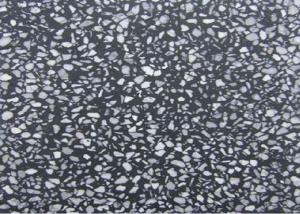

AR fiberglass mat ZrO2 16.7 content

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Date Sheet for ZrO2 16.7% AR fiberglass mat

Product Info.:AR GLASSFIBRE CHOPPED STRAND MAT

ARMC150-1000mmH ZrO2 ≥16.5%

Application: For Cement or concrete reinforcement (GRC)

Test Condition:Temperature & Humidity 24℃ 56%

Material properties:

1、Type of Glass Alkali Resiatant (AR)

2、ZrO2 content % ≥16.5

3、Specific density g/m3 2.68

4、Filament dia. um 11±2

5、Strand Tex tex 50±5

6、Cut fiber length mm 40-50

7、Mass per unit area g/㎡ 150

8、Width mm 1000

9、Thickness mm 0.5

10、Size content % 9

11、Breaking strength N/150mm 37

--------------------------------------------------------------------------------------------------------------

Packing details: 100M2 /Roll /ctn,16ctns/pallet,20pallets/1*20’FCL. 32000m2.

AR Fiberglass Mat is an engineered designed for use in the reinforcement of very thin layer (5-25 mm

AR Fiberglass Mat has a high elastic modulus and tensile strength, making them ideal as an effective reinforcement for cement matrices. They will not rot or corrode, and are unaffected by UV radiation, making them suitable for use with minimal cover.

AR Fiberglass Matis available in a range of nominal weight: Standard is 120 G/M2. It is produced by chopping Huierjie AR-rovings into 20-50mm strands and forming into a mat with a suitable binder. The mat has an open construction to permit penetration by cement mortar. The engineered binder, which dissolves with water further, assists incorporation into a cement matrix.

AR Fiberglass Matmay be used as a positioned reinforcement flooring systems.

- Q: Decrease in water/cement ratio will??1)increase in strength 2)Difficult to obtain a smooth finished surface3)Decrease in strength4)Reduction in long term durability Increase in water/cement ratio will??1)Increase in strength 2)Difficult to obtain a smooth finished surface3)Decrease in strength4)Reduction in long term durability

- Decrease in water/cement ratio will? Increase in strength Increase in water/cement ratio will? Decrease in strength Cheers and good luck!

- Q: when the dentist put the crown on to check to fit, he couldnt remove it to put the cement, if he did he said it'd break.it doesnt seem loose but when i bite i canfeel something happening under the crown. and when i bite down on my tongue it causes a foul odor in my mouth. im scarred :/

- Actually I have seen such a good fit that they did not require cement before. I have placed and fitted thousands of permanent crowns to prepare the crown to be ready before the dentist comes in and permanently cements it. When the crown is on it should snap into place without being too loose or too tight. The floss on both sides of the tooth should also go between the tooth without too much space or too tight to place the floss and without shredding the floss. Since your having issues I would have them take the chance of removing it with it breaking, it may or may not. If it breaks they need to re send the impression to lab and have them make a new temporary crown. @michelle I understand going by the book, I was saying I have seen a person who had a crown on without cement from another office and when it was removed (with a handpiece) there was no decay under it. Sometimes the crown prepped tooth is so fragile and small that the trauma from removing it can also break the tooth.

- Q: I know they say babies don't keep a man but it is a lifelong commitment so why not?weather the relationship is good or bad I truly do believe a baby is a way to cement that man into your life?Why do I feel like this?

- why dont you have the baby as your romantic relationship.

- Q: What s d chemical composition of lime and cement?

- which lime? limestone is CaCO3, Quick lime is CaO and slaked lime is Ca(OH)2 chemical composition of cement? this is a stupid question. Cement is a mixture of not precisely known composition, as different compositions are required for different applications. But, as an example, here's a breakdown of the chemical formulas used in portland cement. It consists of five compounds as listed below. 50% - Tricalcium silicate - Ca3SiO5 or 3CaO.SiO2 25% - Dicalcium silicate - Ca2SiO4 or 2CaO.SiO2 10% - Tricalcium aluminate - Ca3Al2O6 or 3CaO .Al2O3 10% - Tetracalcium aluminoferrite - Ca4Al2Fe2O10 or 4CaO.Al2O3.Fe2O3 5% - Gypsum - CaSO4.2H2O

- Q: what is the ratio for the cement to install cement block; sand, cement . and mortor creme?

- Easiest thing to do is just buy mortar mix, but if you insist on the hard way, mix 100 lb. bag of portland cement and 22 shovelfuls of sand. Enjoy! ( Never, ever heard of mortar creme, is that a new product?)

- Q: ok im building on big open stall for my 2 horses but part of the barn where the stall will be has cement under the dirt so we cant put any posts down anyone have any idea's of how i can get this to work? there is only about 5 inches of dirt on top of the cement. so what can i do?

- We have a cement 'deck' out the back of our house and a porch roof thing got built on top of that and they used those footer things for it. They are like huge metal brackets that they bolt down into the concrete and they can then bolt the posts into the bracket. It is totally possible to do! (I am also assuming you are talking about a slab and not just ruble)

- Q: please tell me the order of increasing strength of cement mixtures1)cement mixed with river sand 2)cement with lime3)cement with pitsand4)cement with rice huski think order is 2 gt; 3gt;4gt;1 (strength)i am not sure.please tell me the correct answer along with explanation.

- we assume the cement (Portland cement) is of the correct ratio. we also assume we are talking about compressive strenght when we have just enough cement to fill the spaces between the rock we have reached the maximum strength. number 2. is no good as it reacts with the cement mixture number 4. allows for compression and cracking of the cement. number 3. .....pits i dont know what is pits number 1. is the same as rock ......the best here so .... the order my guess ....... 2,4,1

- Q: in the dream, i got a job helping this old lady. She showed me under her counter and her daughter was kept under there because she had a mole, like the animal, growing out of her stomache. The daughter had babies and they were covered in cement. There was also a cement covered chicken. The old lady showed me a video of the babies getting baptized but it was actually a priest holding them up the putting them in a bath tub of cement. Later on I told the police and there was something weird, and then it went off where my friend and me were at a phone booth for a few hours so she could get cheap plane tickets. It was really really weird, any idea's what this could mean?

- Stop huffing paint, that's what it means.

- Q: Make the yard with cement is cheaper or brick is cheaper? thanks!?

- Cement is cheaper, by far. And you can color it and stamp textured to make it look like brick.

- Q: Thought to be Lafarge cement, after 3 or 4 months should it start to deteriorate? If so why is this?

- A bit vague, but in general no cement should start to deteriorate so quickly. Was the reinforcement rusty? That will cause spalling (bursting of the concrete) Also a bad mix or improper curing (curing can be immensely important in some applications). There are also any number of chemicals which will deteriorate concrete and many of them are found right there in the ground, but this should take years to occur. If this came out of a Lafarge truck, there is always the possibility that you got a mix intended for someone else (this happens more often than many realize) There really is no excuse for cement to fail so quickly, if this was a pro job I'd have them back ASAP. If it was a personal job, check your delivery docket and if all is well, call the batch plant and get one of the concrete guys out there to take a look. It's rare, but sometimes you just get a bad batch.

Send your message to us

AR fiberglass mat ZrO2 16.7 content

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords