Anodized Aluminum Sheets for Aircraft and Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Anodised Aluminum Rolls for Curtain Wall System

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Anodised Aluminum Rolls for Curtain Wall System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

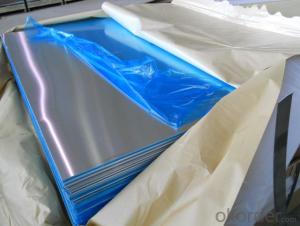

3. Anodised Aluminum Rolls for Curtain Wall System Images

4.Specification of Anodised Aluminum Rolls for Curtain Wall System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the lifespan of an aluminum sheet?

- Factors such as the grade of aluminum, sheet thickness, environmental exposure, and maintenance level can all influence the lifespan of an aluminum sheet. Aluminum sheets are generally recognized for their durability and extended longevity. Aluminum possesses corrosion resistance, enabling it to endure moisture and environmental elements without deteriorating rapidly, unlike other materials. This quality makes aluminum sheets highly resistant to rust and corrosion, thereby significantly increasing their lifespan. Typically, aluminum sheets can endure for 20 to 50 years, and sometimes even longer. However, it is important to consider that this estimate may vary depending on the specific application and conditions to which the sheet is subjected. For instance, aluminum sheets utilized in outdoor applications like roofing or siding may have a shorter lifespan due to exposure to harsh weather conditions such as UV radiation, extreme temperatures, and heavy rainfall. To maximize the lifespan of an aluminum sheet, proper maintenance and care are vital. This entails regular cleaning to eliminate any accumulated dirt or debris that may potentially cause damage. Additionally, applying protective coatings or treatments can further enhance the sheet's resistance to corrosion, thus extending its lifespan. Overall, when adequately maintained and used in suitable applications, aluminum sheets can boast a lengthy lifespan. This makes them a dependable and cost-effective choice for diverse industries and purposes.

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Let's fix it for you. We can't do the coil. We do hot plated pure aluminum steel plate

- Q: the coil is wrapped around the aluminium pipe will it effect the efficiency of the coil gun ?

- Hopefully yes.

- Q: Can 101 aluminum sheets be perforated?

- Indeed, it is possible to perforate 101 aluminum sheets. Perforation involves the creation of a hole pattern in a material, and aluminum is frequently chosen for this purpose due to its adaptable and sturdy nature. The inclusion of the number "101" likely denotes the alloy type or specific grade of aluminum, which has no bearing on its perforatability. Hence, accomplishing the perforation of 101 aluminum sheets is easily achievable through several techniques such as punching, laser cutting, or drilling, contingent upon the desired hole pattern and size.

- Q: How do you calculate the weight of an aluminum sheet?

- To determine the weight of an aluminum sheet, one must take into account its dimensions (length, width, and thickness) as well as the density of aluminum. Initially, one should measure the length, width, and thickness of the aluminum sheet in either inches or millimeters. It is crucial to use a consistent unit of measurement throughout the calculation. Subsequently, if necessary, the dimensions should be converted to feet or meters. For instance, if the dimensions are in inches, divide each value by 12 to convert them to feet. To ascertain the volume of the aluminum sheet, multiply the length, width, and thickness together. In case the dimensions are in different units, they must be converted to the same unit before multiplying. Next, consult a reference for the density of aluminum. Aluminum's density is approximately 2.7 grams per cubic centimeter or 2700 kilograms per cubic meter. Convert the volume of the aluminum sheet to the same unit as the density. For example, if the density is in kilograms per cubic meter and the volume is in cubic feet, multiply the volume by 0.0283 to convert it to cubic meters. Lastly, multiply the volume of the aluminum sheet by the density of aluminum to determine the weight of the sheet. The resulting weight will be in grams or kilograms if the density was in grams per cubic centimeter, or in kilograms or metric tons if the density was in kilograms per cubic meter. It is important to note that this calculation assumes a uniform thickness throughout the aluminum sheet. If the sheet has varying thicknesses, one must calculate the weight of each section individually and then sum them to find the total weight.

- Q: Can the aluminum sheets be used for printing applications?

- Yes, aluminum sheets can be used for printing applications. Aluminum provides a smooth and flat surface, making it ideal for printing graphics, images, and text. The sheets can be easily printed on using various printing methods such as offset printing, screen printing, and digital printing. Printing on aluminum sheets offers durability, resistance to fading and weathering, and a professional and sleek appearance. It is commonly used for signage, labels, nameplates, and decorative purposes in industries like advertising, automotive, aerospace, and packaging.

- Q: What is the cost of an aluminum sheet?

- The cost of an aluminum sheet can vary depending on factors such as size, thickness, and quality. It is recommended to check with suppliers or conduct market research to get accurate and up-to-date pricing information.

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Discover Spray Paint Art Secrets!

- Q: Can aluminum sheets be welded or joined together?

- Indeed, welding or joining together aluminum sheets is possible. Aluminum possesses excellent weldability, allowing for its fusion through diverse welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. These methods involve the application of heat to liquefy the aluminum sheets and establish a robust connection. Furthermore, mechanical fasteners like screws, rivets, or adhesive bonding can also be employed to join aluminum sheets. The selection of the welding or joining approach hinges upon the particular application and the desired result.

Send your message to us

Anodized Aluminum Sheets for Aircraft and Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords