Aluminum solar moudle frame AA6061

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Material:

Aluminum alloy6061/6063 T3-T8 or follow customer’s demand.( Aluminium profile for PV solar panel frame)

Surface treatment:

1.Anodizing: silver/black mainly and other multicolor.

2.Electrophoresis

3.Powder coating/ PVDF polishing/ sand blasting etc.

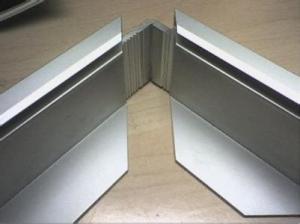

Two types:

1) 90-angle

2) 45-angle

Specifications:

1)30*25mm suitable for 30-120W solar modules.

2)35*35mm suitable for 160-220W solar modules.

3)40*35/45*35/50*35 suitable for 200w above.

The size are available in accordance with customers' requirement.

- Q:How do aluminum profiles perform in terms of chemical resistance?

- Aluminum profiles exhibit good chemical resistance to many common substances, including water, air, various acids, and alkalis. However, they may corrode or react with certain aggressive chemicals, such as strong acids or bases. It is important to consider the specific chemical environment and consult relevant guidelines or experts when assessing the chemical resistance of aluminum profiles.

- Q:Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. Aluminum is a versatile and lightweight material that offers various benefits for exhibition booth construction. Firstly, aluminum profiles are easy to work with and can be easily cut, drilled, and assembled to create custom booth designs. This flexibility allows for creativity and customization to meet specific booth requirements. Additionally, aluminum profiles are highly durable and long-lasting. They are resistant to corrosion, rust, and other environmental factors, which ensures that the exhibition booth can withstand the rigors of multiple events and maintain its appearance over time. This durability also makes aluminum profiles a cost-effective choice, as they require minimal maintenance and can be reused for future exhibitions. Furthermore, aluminum profiles offer a sleek and professional aesthetic that can enhance the overall presentation of the exhibition booth. The material can be finished with various coatings, such as paint or anodizing, to achieve the desired look and branding. Moreover, aluminum profiles can be easily integrated with other materials, such as glass, acrylic, or fabric, to create visually appealing displays within the booth. Lastly, aluminum profiles provide structural stability while remaining lightweight. This is crucial for exhibitors who need to transport and assemble their booths frequently. The lightweight nature of aluminum profiles makes them easy to handle, reducing logistical challenges and costs associated with booth setup and dismantling. Overall, aluminum profiles offer numerous advantages that make them suitable for exhibition booths. Their versatility, durability, aesthetic appeal, and ease of use make them an excellent choice for exhibitors looking to create eye-catching and functional booth designs.

- Q:Are aluminum profiles suitable for cleanroom partitions?

- Yes, aluminum profiles are suitable for cleanroom partitions. They offer a lightweight and durable solution that is resistant to corrosion and easy to clean, making them ideal for maintaining a clean and sterile environment in cleanrooms. Additionally, aluminum profiles can be customized to fit specific requirements, allowing for flexibility in design and construction.

- Q:What are the color options available for aluminum profiles?

- The color options available for aluminum profiles are vast and diverse. Standard options usually include silver, bronze, and black anodized finishes. However, these profiles can also be powder-coated in a wide range of colors, allowing for customization to match any aesthetic or design preference.

- Q:Can aluminum profiles be used in the construction of retail displays?

- Yes, aluminum profiles can be used in the construction of retail displays. Aluminum is a versatile and lightweight material that is commonly used in various industries, including construction and retail. It offers several advantages for retail displays, such as durability, corrosion resistance, and ease of customization. Aluminum profiles can be easily shaped and fabricated to create different types of retail displays, such as shelving units, display stands, signage frames, and product showcases. These profiles can be extruded into different shapes and sizes, allowing for flexibility in design and functionality. Additionally, aluminum profiles can be finished with various surface treatments, such as anodizing or powder coating, to enhance their appearance and provide a protective layer against scratches and wear. This allows retail displays to maintain their aesthetic appeal and withstand the demands of a retail environment. Furthermore, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for retail displays. It can be easily recycled without losing its properties, reducing the environmental impact of construction and retail industries. In summary, aluminum profiles are a suitable and practical choice for the construction of retail displays. They offer durability, versatility, and customization options while being lightweight and environmentally friendly.

- Q:What are the different types of corner connectors used with aluminum profiles?

- Aluminum profiles commonly utilize several types of corner connectors for joining. These connectors facilitate the creation of diverse structures like frames, enclosures, and shelving units. One prevalent corner connector is the 90-degree angle bracket. It possesses a right angle shape with holes on each side to accommodate screws or bolts for fastening the profiles together. The 90-degree angle bracket is adaptable and suitable for various applications. Another corner connector is the 45-degree angle bracket, similar to the 90-degree angle bracket but designed for a 45-degree angle joint between profiles. It finds use in applications requiring slanted or angled structures. T-slot corner connectors are also popular. They have a T-shaped slot for easy insertion of profiles. These connectors are ideal for applications that prioritize adjustability and flexibility, allowing for effortless repositioning and modification of the structure. Some corner connectors are specifically designed for particular profile types, such as the end cap connector. This connector caps off the profile's end, providing a polished appearance and protection against damage. Furthermore, various other corner connectors exist, including corner gussets, angle plates, and corner brackets. Each connector type offers unique features and advantages, catering to different applications and requirements. In summary, the assortment of corner connectors available for aluminum profiles offers a wide range of options for joining and assembling structures. These connectors provide strength, stability, and versatility, making them indispensable components in aluminum profile-based construction projects.

- Q:How are aluminum profiles cut and shaped?

- Aluminum profiles can be cut and shaped using a variety of methods depending on the desired outcome. One common method is cutting the profiles using a saw. This can be done manually with a hand saw or by using a power saw such as a miter saw or a circular saw. These saws are equipped with specially designed blades that are capable of cutting through aluminum. Another method is using a CNC (Computer Numerical Control) machine. CNC machines are highly precise and can be programmed to cut and shape aluminum profiles with great accuracy. This method is often used for more complex and intricate designs. In addition to cutting, aluminum profiles can also be shaped using various techniques. One common method is bending. Aluminum profiles can be bent to a desired angle using specialized bending machines. These machines use force to gradually shape the aluminum without causing any damage or deformation. Another shaping technique is extrusion. Extrusion involves forcing the aluminum through a die to create a specific shape. This method is commonly used in the manufacturing of aluminum profiles with consistent cross-sectional shapes such as tubes or beams. Overall, the cutting and shaping of aluminum profiles require specialized tools and machinery to achieve the desired results. The specific method used will depend on the complexity of the design and the desired outcome.

- Q:Can aluminum profiles be used in the construction of modular office spaces?

- Yes, aluminum profiles can be used in the construction of modular office spaces. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them an ideal choice for modular construction. They can be easily fabricated into various shapes and sizes, allowing for versatility in design. Additionally, aluminum profiles offer excellent thermal insulation properties and can be easily integrated with other building components, such as glass panels or insulation materials.

- Q:How do you protect aluminum profiles from scratching or damage?

- There are multiple methods available for safeguarding aluminum profiles against scratches or damage. To begin with, a commonly used approach involves applying a protective coating or finish. This can be accomplished by utilizing paints, lacquers, or powder coatings that serve as a barrier between the aluminum surface and external elements. These coatings not only enhance the appearance but also offer protection against scratches, corrosion, and other forms of damage. Another effective temporary solution is the utilization of protective film or tape. These films or tapes can be directly applied onto the aluminum profiles, acting as a shield. Generally transparent, these films can be easily peeled off once the profiles are installed or ready for use. A different technique involves handling and transporting the aluminum profiles with caution. This entails the use of appropriate handling equipment, such as gloves, to avoid direct contact with the surface. Additionally, the use of protective packaging materials like bubble wrap or foam can provide cushioning during transportation, preventing scratches or dents. Regular cleaning and maintenance of the aluminum profiles is also crucial. Dust, dirt, and debris can act as abrasives, causing scratches over time. Cleaning with a soft cloth or sponge and mild detergent on a regular basis can help eliminate these particles and preserve the profile's appearance. Lastly, implementing proper storage practices is of utmost importance. Storing aluminum profiles in a dry and clean environment, away from sharp objects or heavy items, can minimize the risk of scratching or damage. The use of racks or shelves with protective padding can provide an additional layer of protection. By adhering to these measures, aluminum profiles can be effectively safeguarded against scratches or damage, ensuring their durability and preserving their aesthetic appeal.

- Q:Can aluminum profiles be used for security doors and windows?

- Yes, aluminum profiles can be used for security doors and windows. Aluminum is a lightweight and durable material that can withstand force and resist corrosion. It can be customized to include additional security features such as multi-point locking systems, reinforced frames, and impact-resistant glass. Additionally, aluminum profiles offer a sleek and modern appearance, making them a popular choice for security doors and windows in residential and commercial properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum solar moudle frame AA6061

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords