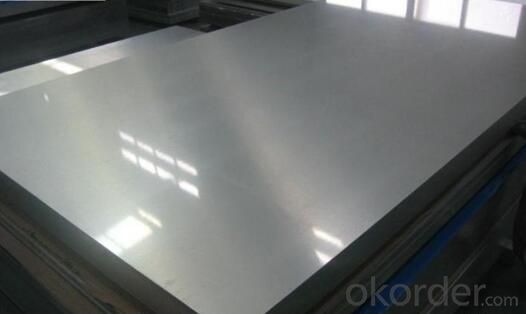

Aluminum Silicon Carbide Sheets - Special Alloy Extrusion Aluminum 1050 Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Can aluminum plate resist acid and alkali?

- Aluminum is a more active metal, easy to react with the acid and alkali of the outside world. If it is in water for a long time, aluminum will react with acid and alkali substances in water. How to improve the acid and alkali resistance of aluminum alloy?Mainly through the oxidation of aluminum alloy, so that its surface with a layer of oxide film, to prevent the external acid-base substances on aluminum alloy corrosion.In order to reduce the surface hardness and wear resistance of aluminum alloy and prolong its service life, the surface oxidation surface treatment technology has become an indispensable part of the use of aluminum alloy.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- The Principle behinf Microwave oven heating is that it heats up only water molecules, that is, the frequency of microwaves can only heat up water molecules ( make them oscillate and hence heat up). So if there is any trace of water or moisture on any object that you keep in the oven, it will heat up and that heat will be conducted throughout the object. Hence the foil with moisture is effectively heated whereas dry foil have no water moecule and hence will not be heated up. Hope it helps:) Can explain better if you tell me which level you are studying:)

- Q: What is the cost of aluminum sheets?

- The cost of aluminum sheets can vary depending on various factors such as the thickness, size, and grade of the aluminum. Additionally, market conditions and supplier pricing policies can also influence the cost. It is recommended to contact local suppliers or search online to get the most accurate and up-to-date pricing information for aluminum sheets.

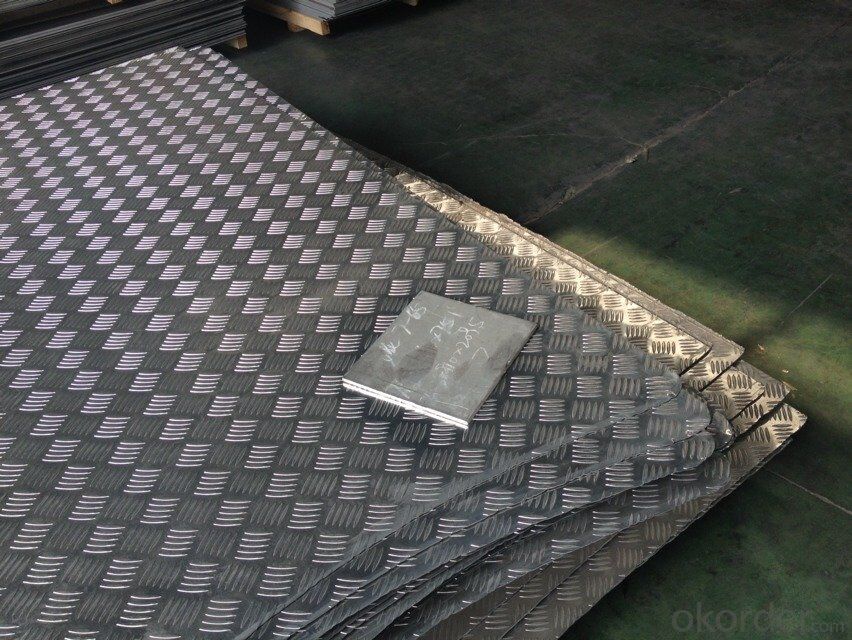

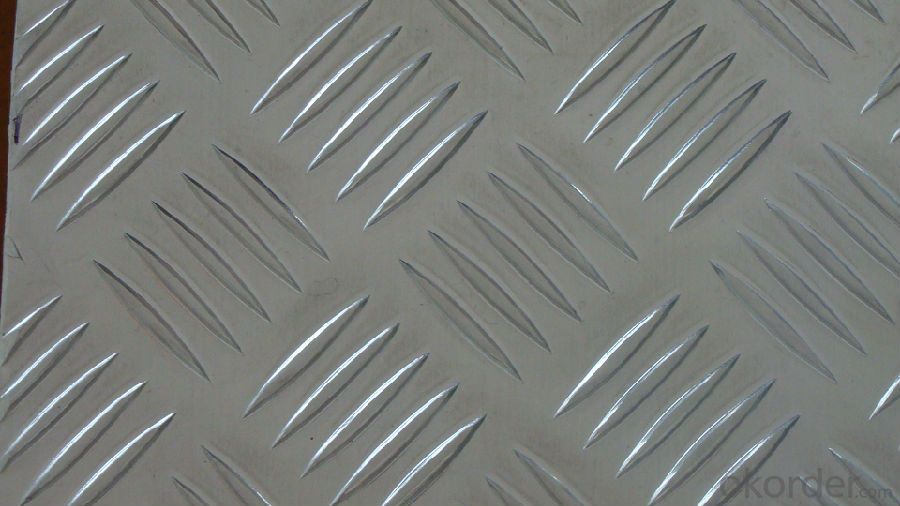

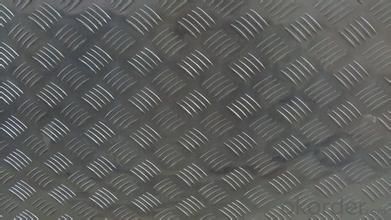

- Q: Can aluminum sheets be embossed or textured?

- Yes, aluminum sheets can be embossed or textured. The process of embossing or texturing aluminum sheets involves creating patterns or designs on the surface by pressing or rolling the sheet with specialized machinery. This can be done to enhance the aesthetic appearance of the sheet or to improve its functionality, such as adding grip or increasing strength. Embossed or textured aluminum sheets are commonly used in various industries, including automotive, interior design, and packaging.

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has excellent thermal conductivity, meaning it can efficiently conduct and transfer heat away from the source. Additionally, aluminum has a high melting point, allowing it to withstand high temperatures without warping or deforming. These properties make aluminum sheets an ideal choice for heat shield applications, such as protecting sensitive components or structures from heat damage in various industries including automotive, aerospace, and industrial applications. Furthermore, aluminum is lightweight and relatively easy to shape, making it a practical choice for heat shields that need to be installed in tight spaces or require complex designs. Overall, the use of aluminum sheets as heat shields offers effective thermal protection while providing durability, versatility, and cost-effectiveness.

- Q: What are the different types of patterns available for textured aluminum sheets?

- There are several different types of patterns available for textured aluminum sheets, each offering a unique visual appeal and functionality. Some of the most common patterns include: 1. Diamond pattern: Also known as tread plate or checker plate, the diamond pattern features small raised diamonds on the surface of the sheet. This pattern offers excellent slip resistance, making it ideal for applications where traction is important, such as ramps, stairs, or industrial flooring. 2. Stucco pattern: The stucco pattern resembles a textured wall or ceiling finish, with raised ridges that create a rough and bumpy surface. This pattern is often used for decorative purposes, adding depth and visual interest to architectural elements like walls, ceilings, or furniture. 3. Hammered pattern: As the name suggests, the hammered pattern mimics the look of a surface that has been hammered by hand, creating a dimpled and uneven texture. This pattern is commonly used in architectural applications, such as wall panels, backsplashes, or decorative accents, to add a rustic and artistic touch. 4. Brushed pattern: The brushed pattern features long, uniform lines that are created by brushing the surface of the aluminum sheet with a wire brush. This pattern offers a sleek and modern appearance, making it popular for applications like kitchen appliances, signage, or interior design elements. 5. Perforated pattern: Unlike the previous patterns, the perforated pattern involves creating small holes across the surface of the aluminum sheet. This pattern is often used in applications that require ventilation, sound absorption, or decorative effects. It can be found in areas such as speaker grills, filters, or façades. These are just a few examples of the different types of patterns available for textured aluminum sheets. The choice of pattern will depend on the specific requirements of the project, including aesthetics, functionality, and durability.

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Yes, aluminum sheets are suitable for manufacturing consumer goods. Aluminum is a lightweight, durable, and corrosion-resistant material that can be easily formed, molded, or cut into various shapes. Its versatility makes it ideal for producing a wide range of consumer goods such as kitchen utensils, packaging materials, electronics, furniture, and automotive parts. Additionally, aluminum is recyclable, making it an environmentally friendly choice for sustainable manufacturing.

- Q: Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer enhances the metal's corrosion resistance, durability, and appearance. Anodizing is commonly used in various industries such as automotive, aerospace, and construction to provide a protective coating and improve the aesthetics of aluminum sheets. The process involves immersing the aluminum sheet in an acid electrolyte solution and passing an electric current through it, causing oxygen ions to bond with the aluminum atoms and form the oxide layer. This layer can be further enhanced with the addition of dyes or pigments to create different colors and finishes. Overall, anodizing is a versatile and effective method for treating aluminum sheets.

- Q: This question asks about the various surface treatments or finishes that can be applied to custom-made aluminum sheets.

- <p>Custom-made aluminum sheets can be finished in a variety of ways to achieve different aesthetic and functional properties. Some of the common finishes include: Anodizing, which provides a protective oxide layer and can be colored; Powder coating, offering a durable and colorful finish; Mill finish, which is the natural surface of the aluminum after rolling; Brushed or Satin finish, giving a鍝戝厜 texture; Mirror finish, providing a reflective, polished surface; and Painted finish, where the aluminum is coated with a layer of paint for color and protection. Each finish serves different purposes, from enhancing corrosion resistance to improving the visual appeal of the aluminum sheet.</p>

- Q: Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- Yes but its for general purpose straight cuts. I've been using a Metabo cutting wheel in lieu of a torch for cutting,including stainless that's 3/16 or less. They work great, are inexpensive, and fit angle grinders.

Send your message to us

Aluminum Silicon Carbide Sheets - Special Alloy Extrusion Aluminum 1050 Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords