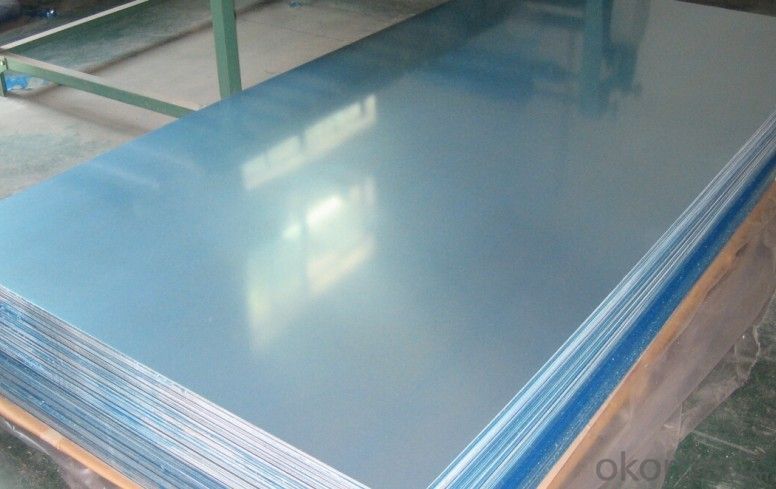

Corrugated Aluminum Sheets - Hot Rolled Anodized Alloy 1060 1070 1050 Thin Aluminum Mirror Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot rolling anodized alloy 1060 1070 1050 thin aluminum mirror sheets

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a highly durable and corrosion-resistant material, making it ideal for outdoor applications. It is lightweight, yet strong enough to withstand harsh weather conditions, such as rain, snow, and UV radiation. Additionally, aluminum sheets can be coated or painted to further enhance their resistance to corrosion and provide added protection against the elements. This makes them a popular choice for outdoor structures, signage, roofing, and other exterior applications where durability and longevity are essential.

- Q: What are the different joining methods for aluminum sheets?

- Aluminum sheets can be joined using various methods, each with its own advantages and considerations. Common techniques for joining aluminum sheets include: 1. Welding: Aluminum sheets can be welded together by melting them and using a filler material. Welding techniques like gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or laser welding are commonly used. Welding creates strong and durable joints, but it requires skilled labor and can be time-consuming. 2. Adhesive bonding: Another method is adhesive bonding, where a specialized adhesive or glue is applied to the surfaces to be joined. Adhesive bonding offers benefits like excellent corrosion resistance, uniform stress distribution, and the ability to join different materials. However, it requires proper surface preparation and can be affected by temperature and humidity. 3. Mechanical fastening: Mechanical fastening involves using bolts, screws, rivets, or clips to join aluminum sheets. It is a simple and cost-effective method that allows for easy disassembly if needed. However, it may create stress concentrations around the fasteners and the joints may not be as strong as welded ones. 4. Friction stir welding: Friction stir welding is a newer method gaining popularity for aluminum sheets. It involves rotating a non-consumable tool along the joint line, generating friction and heat that softens and joins the sheets. Friction stir welding offers benefits like high joint strength, low distortion, and defect-free welds. However, it requires specialized equipment and is limited to certain sheet thicknesses. 5. Clinching: Clinching is a cold joining method that deforms the sheets using a punch and die without melting them. The sheets are pressed together under high pressure, creating a mechanical interlock. Clinching is a fast and cost-effective method that doesn't require additional materials, but it may cause visible surface deformation. When choosing a joining method for aluminum sheets, factors like joint strength, corrosion resistance, aesthetics, production cost, and specific application requirements should be considered. Each method has its own advantages and limitations, so the most suitable technique depends on the project's specific needs.

- Q: Is the chemical formula for Aluminum Sulfate Al2(SO4)3?How and why is Al2(SO4)3 wrong?

- Aluminum Sulfate Formula

- Q: This question asks for the various types of surface treatments or coatings that can be applied to aluminum profiles to enhance their properties or appearance.

- <p>Aluminum profiles can be coated with several types of finishes to improve their aesthetic appeal, durability, and corrosion resistance. The common types include: 1) Anodizing, which creates a protective oxide layer on the aluminum surface; 2) Powder coating, where a dry powder is electrostatically applied and then cured under heat; 3) Electrophoretic coating, a method where charged particles adhere to the aluminum and then harden; 4) PVDF (Polyvinylidene Fluoride) coating, known for its excellent weather resistance and durability; 5) Thermal spraying, where a coating material is melted and sprayed onto the aluminum surface; and 6) Painting, which can be done through various methods such as airless spray or dip coating. Each type of coating serves different purposes and has its own set of advantages and applications.</p>

- Q: why can aluminum sheet after oxide film removal react quicker with hydrochloric acid?

- the reason is very simple, the original aluminum sheet has a layer of dense oxide film AI2O3, which has prevented the inner aluminum sheet from reacting with hydrochloric acid. but after oxide film removal, aluminum sheet will directly contact hydrochloric acid, generating H2.

- Q: How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The cost of 101 aluminum sheets may fluctuate based on various factors like market conditions, demand, and supply. Nonetheless, in general, 101 aluminum alloy is regarded as one of the more affordable choices among aluminum alloys. It is a popular option due to its relatively low price and satisfactory overall performance. When compared to other aluminum alloys, particularly high-strength alloys like 7075 or 6061, 101 aluminum sheets tend to be less expensive. This is because 101 aluminum is a relatively uncomplicated alloy with a lower content of alloying elements, resulting in lower production costs. However, it is important to note that the price difference between aluminum alloys can vary depending on current market conditions and specific requirements. Factors such as sheet thickness, size, and quantity can also impact the final price. Therefore, it is always advisable to consult suppliers or manufacturers to obtain the most accurate and up-to-date pricing information for 101 aluminum sheets in comparison to other aluminum alloys.

- Q: Can 101 aluminum sheets be painted or coated?

- Yes, aluminum sheets can be painted or coated. Aluminum is a versatile material that can be treated with various finishes, such as paint or coating, to enhance its appearance and provide protection against corrosion. Whether it is 101 aluminum sheets or any other type of aluminum, they can be painted or coated using different methods such as spray painting, powder coating, or anodizing. The choice of paint or coating will depend on the desired aesthetics, performance requirements, and the specific application of the aluminum sheets.

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that can be easily manipulated to create various designs and finishes. It is lightweight, durable, and offers a sleek and modern look, making it a popular choice for decorative wall applications.

- Q: What is the typical fatigue life of aluminum sheets?

- The typical fatigue life of aluminum sheets can vary depending on several factors such as the alloy used, sheet thickness, manufacturing process, and the specific application it is being used for. Generally, aluminum sheets have a relatively high fatigue strength compared to other materials, allowing them to withstand a large number of cyclic loading cycles before failure. However, it is important to note that fatigue life can be influenced by various factors such as stress levels, loading conditions, and environmental factors like temperature and humidity. Aluminum sheets may experience a decrease in fatigue life when subjected to high stress levels, cyclic loading, or harsh environmental conditions. In certain applications where aluminum sheets are subjected to low stress levels or are not exposed to cyclic loading, they can have an infinite fatigue life. On the other hand, in high-stress applications or when subjected to cyclic loading, aluminum sheets typically have a finite fatigue life that can range from thousands to millions of cycles. To determine the precise fatigue life of aluminum sheets for a specific application, it is recommended to refer to relevant industry standards, test data, or consult with material engineers or manufacturers who can provide more accurate information based on the specific parameters and conditions of use.

Send your message to us

Corrugated Aluminum Sheets - Hot Rolled Anodized Alloy 1060 1070 1050 Thin Aluminum Mirror Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords