Aluminum Sheet Metalt for PCB,Good Use for PCB Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications

| 1) Chemical ingredients: | According with the rules of GB /T3190-1996 |

| 2) Physical property: | The physical property testing of basis material under room |

| Temperature accords with the rules of GB /T8544-1997 | |

| 3) Appearance quality: | Clear patern and tidy without burr |

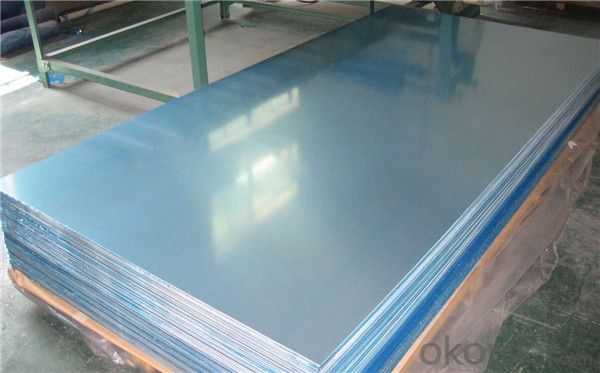

| 4) Surface: | No crack, selvedge, canker, hole Specifications1.Alloy:1100 1050 1060 1070 3003 3105 3005 5005 5052 5083 8011 ,etc 6. Length:Under 6000mm 7. Weight: 0.5-3.5 tons per pallet or according to customer's requirement

1) Chemical ingredients:According with the rules of GB /T31902) Physical property:The physical property testing of basis material under roomTemperature accords with the rules of GB /T8544-19973) Appearance quality:Clear patern and tidy without burr4) Surface:No crack, selvedge, canker, hole |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

Photos

- Q:How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q:Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight, durable, and corrosion-resistant properties. It is also easy to work with and can be easily shaped and formed to fit various duct designs.

- Q:Are aluminum sheets suitable for food packaging?

- Yes, aluminum sheets are suitable for food packaging. Aluminum is a highly versatile and widely used material in the food industry due to its unique properties. It is lightweight, flexible, and has excellent barrier properties that protect the contents from external factors such as moisture, light, and oxygen. These properties help to maintain the freshness and quality of food products. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline substances, ensuring that the taste and quality of the food is preserved. Furthermore, aluminum sheets can be easily shaped into different forms, making them ideal for various types of food packaging such as trays, containers, and foil wraps. Overall, aluminum sheets are a safe and effective choice for food packaging, providing durability, protection, and convenience.

- Q:I know that aluminum doesn't belong in the human body. As a canister to hold liquids which will be consumed later, is aluminum good or bad to use?

- I okorder /

- Q:How does the thickness of aluminum sheet affect its formability?

- The thickness of an aluminum sheet has a significant impact on its formability. Generally, thinner sheets of aluminum are more malleable and easier to shape compared to thicker sheets. This is because thinner sheets have lower resistance to deformation and require less force to bend or stretch. Thicker aluminum sheets, on the other hand, have higher resistance to deformation and are less malleable. They require more force and energy to shape, and may be more prone to cracking or tearing during forming processes. Thicker sheets also have a higher likelihood of experiencing springback, where the material partially returns to its original shape after being formed. The formability of aluminum sheets is also influenced by the alloy composition and the specific forming process being used. In some cases, certain alloy compositions or heat treatments can enhance the formability of thicker sheets, making them easier to shape. In summary, the thickness of an aluminum sheet directly affects its formability. Thinner sheets are generally more malleable and easier to shape, while thicker sheets require more force and are less malleable. The alloy composition and specific forming processes being used can also impact the formability of aluminum sheets.

- Q:What are the different alloys available for aluminum sheets?

- There are several different alloys available for aluminum sheets, each with its own unique properties and applications. Some of the most common alloys include: 1. 1100: This is a commercially pure aluminum alloy with excellent corrosion resistance, making it suitable for applications where high levels of corrosion resistance are required, such as in marine environments. 2. 3003: Another commercially pure alloy, 3003 offers good formability, high corrosion resistance, and moderate strength. It is commonly used for general sheet metal work, cooking utensils, and chemical equipment. 3. 5052: This alloy is known for its high fatigue strength and excellent corrosion resistance, particularly in saltwater environments. It is often used in marine applications, as well as for aircraft components and fuel tanks. 4. 6061: A heat-treatable alloy, 6061 exhibits good weldability and formability, along with high strength and excellent corrosion resistance. It is commonly used in structural components, such as frames and railings, as well as automotive parts. 5. 7075: This alloy is known for its high strength-to-weight ratio, making it ideal for aerospace applications and high-stress structural components. However, it is less corrosion resistant than other alloys and may require protective coatings in certain environments. These are just a few examples of the alloys available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost. It is important to consult with a knowledgeable supplier or engineer to determine the most suitable alloy for your specific needs.

- Q:What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically determined by the specific alloy and thickness of the sheets. Aluminum has a relatively low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which means it can deform or melt under high heat. However, it is worth noting that aluminum is a non-combustible material and does not contribute to the spread of fire. Its fire resistance can be enhanced through the use of fire-resistant coatings or by combining it with other fire-resistant materials. Ultimately, it is important to consult with manufacturers or industry experts to determine the fire rating of specific 101 aluminum sheets.

- Q:Can the aluminum sheets be used for manufacturing medical equipment?

- Yes, aluminum sheets can be used for manufacturing medical equipment. Aluminum is a versatile and widely used material in various industries, including healthcare. It has several properties that make it suitable for medical equipment manufacturing. Firstly, aluminum is lightweight yet durable, which is beneficial for portable medical devices. It allows for easier handling and transportation of equipment, especially for healthcare professionals who may need to move them frequently. Secondly, aluminum has excellent corrosion resistance, making it suitable for medical applications where cleanliness and hygiene are crucial. It can withstand disinfection processes without deteriorating, ensuring the longevity of the equipment. Additionally, aluminum can be easily sterilized, which is essential for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without any adverse effects on its structural integrity. Moreover, aluminum is an excellent conductor of heat and electricity. This property is advantageous for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is a non-toxic material, making it safe for medical use. It does not leach harmful substances, ensuring that it does not pose any health risks to patients or healthcare professionals. In conclusion, aluminum sheets can indeed be used for manufacturing medical equipment due to their lightweight, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, and non-toxic nature. These properties make aluminum a suitable choice for various medical applications, contributing to the advancement of healthcare technology.

- Q:Are aluminum sheets suitable for electrical bus bars?

- Certain applications may find aluminum sheets suitable for use in electrical bus bars. Aluminum possesses several properties that make it a viable choice for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in situations where weight reduction is crucial. Furthermore, aluminum exhibits good electrical conductivity, although it falls short of copper in terms of conductivity. Nevertheless, aluminum bus bars can still handle high electrical currents and are commonly employed in power distribution systems. However, one drawback of aluminum bus bars is their higher resistance compared to copper bus bars. Consequently, they have a tendency to generate more heat, particularly under heavy current loads. To address this issue, aluminum bus bars are often designed with larger cross-sectional areas to minimize resistance and dissipate heat more effectively. Another challenge associated with aluminum bus bars is their vulnerability to oxidation and corrosion. This concern can be tackled by applying protective coatings or utilizing alloys that offer superior corrosion resistance. Additionally, it is crucial to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In conclusion, aluminum sheets can serve as suitable materials for electrical bus bars, particularly in scenarios where weight reduction is a priority. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q:Can aluminum sheets be custom cut to specific dimensions?

- Yes, aluminum sheets can be custom cut to specific dimensions. Aluminum is a versatile material that can be easily cut and shaped using various tools and techniques. This allows for precise customization to meet specific requirements and dimensions. Whether it is for industrial, commercial, or residential applications, aluminum sheets can be accurately cut to desired sizes, ensuring a perfect fit and functionality. Additionally, custom cutting aluminum sheets allows for flexibility in design and enables the creation of unique and tailored solutions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheet Metalt for PCB,Good Use for PCB Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords