Aluminum Heat Sink Extrusion Profiles for Window and Door with Advantage Price and Free Moulds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Window and Door with Advantage Price and Free Moulds Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Window and Door with Advantage Price and Free Moulds:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

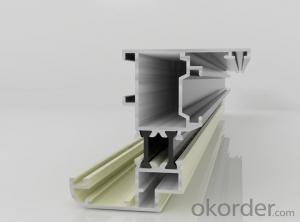

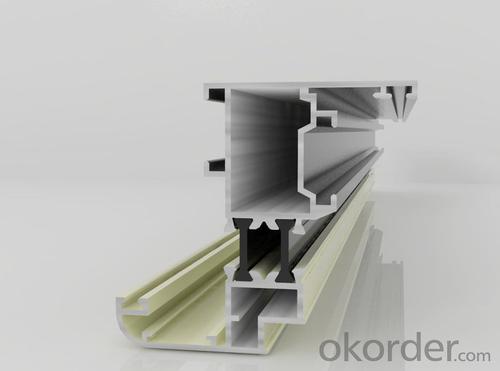

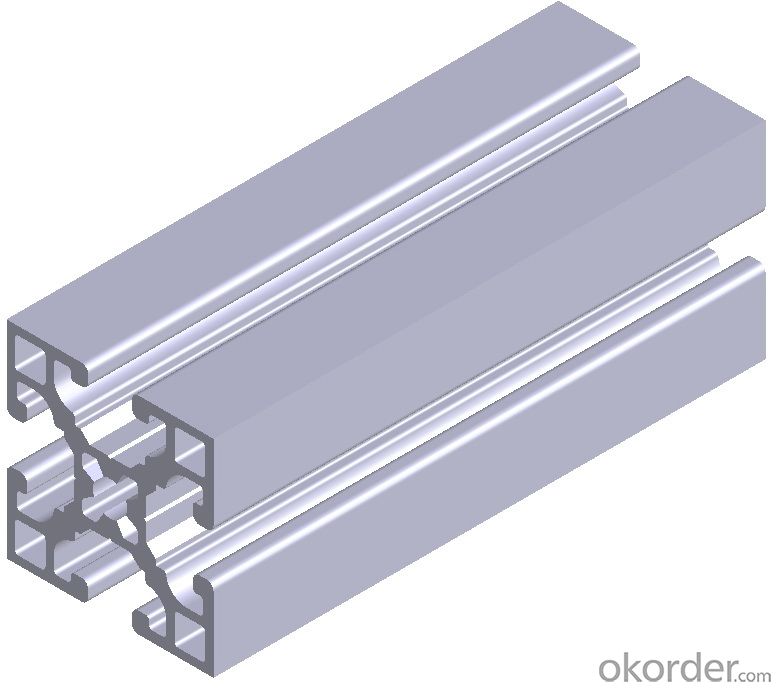

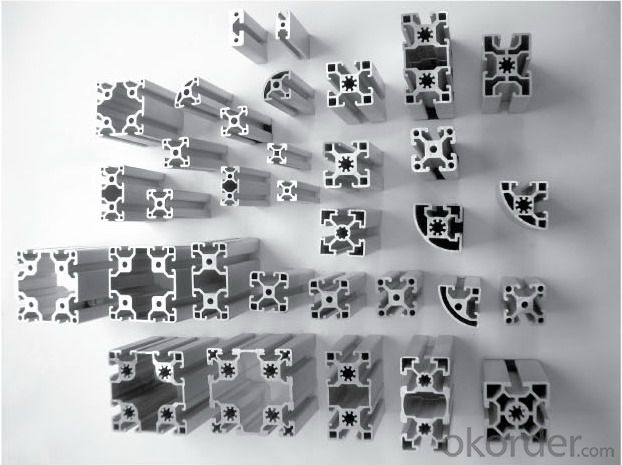

Images of the Aluminium Profile for Window and Door with Advantage Price and Free Moulds:

Aluminium Profile for Window and Door with Advantage Price and Free Moulds Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: What are the advantages of industrial aluminum profiles? What are the problems that should be paid attention to?

- Among a large number of aluminum processing materials, a large number of international advanced products and national famous brand products have emerged, representing the mainstream of the development and application of modern aluminum processing technology in china.

- Q: Can aluminum profiles be used in agricultural greenhouse manufacturing?

- Yes, aluminum profiles can be used in agricultural greenhouse manufacturing. Aluminum profiles are lightweight, strong, and resistant to corrosion, making them suitable for constructing greenhouse structures. Additionally, their versatility allows for customization and easy installation of various greenhouse components.

- Q: Can aluminum profiles be used in automotive applications?

- Yes, aluminum profiles can be used in automotive applications. Aluminum profiles are lightweight, strong, and corrosion-resistant, making them suitable for various automotive components such as body panels, chassis parts, and engine components. Their use helps reduce the overall weight of the vehicle, improving fuel efficiency and performance.

- Q: What are the different surface brushing options for aluminum profiles?

- There are several surface brushing options available for aluminum profiles, each offering unique aesthetics and functional characteristics. 1. Mechanical Brushing: This method involves using abrasive brushes or pads to create a uniform brushed pattern on the surface of the aluminum profile. It provides a consistent, linear finish that enhances the visual appeal of the material. Mechanical brushing also helps to hide minor surface imperfections and scratches, making it a popular choice for decorative applications. 2. Chemical Brushing: Chemical brushing, also known as chemical etching, involves applying a chemical solution to the surface of the aluminum profile. The solution selectively removes a thin layer of metal, creating a brushed effect. This process can be controlled to achieve different levels of brush intensity, giving manufacturers flexibility in creating the desired appearance. Chemical brushing is often used to create a matte or satin finish on aluminum profiles. 3. Sandblasting: Sandblasting is a surface treatment technique that involves propelling fine particles at high speeds onto the aluminum profile's surface. The abrasive particles remove the outer layer of the metal, resulting in a textured, brushed finish. Sandblasting can be adjusted to achieve different levels of roughness and depth, making it suitable for various applications. 4. Wire Brushing: Wire brushing is a manual technique where a wire brush is used to create a brushed pattern on the aluminum profile's surface. This method allows for precise control over the brushing direction and intensity, making it suitable for customized designs. Wire brushing can create both light and heavy brushed finishes, depending on the pressure applied and the type of brush used. 5. Anodizing: Anodizing is an electrochemical process that involves creating an oxide layer on the surface of the aluminum profile. This process not only enhances the material's corrosion resistance but also allows for the application of various decorative finishes, including brushed patterns. Anodized aluminum profiles can be mechanically brushed or chemically etched to achieve the desired brushed effect before the anodizing process. Overall, the choice of surface brushing option for aluminum profiles depends on the desired finish, functionality, and specific application requirements. Manufacturers often consider factors such as aesthetic appeal, durability, corrosion resistance, and ease of maintenance when selecting the appropriate surface brushing technique.

- Q: Can aluminum profiles be used in food-grade applications?

- Yes, aluminum profiles can be used in food-grade applications. Aluminum is a non-toxic, lightweight, and corrosion-resistant metal that is commonly used in the food industry. It is often used to fabricate food processing equipment, such as conveyor systems, tanks, shelves, and frames. Aluminum profiles can also be used in the construction of cleanrooms and other sanitary environments where food is processed or stored. Additionally, aluminum is easily cleaned and sanitized, making it a suitable material for food-grade applications. However, it is important to ensure that the aluminum profiles used are specifically designed for food-grade applications and comply with relevant regulations and standards to ensure the safety and quality of the food being processed or stored.

- Q: The question asks if aluminum profiles can be tailored to fit particular specifications or needs.

- <p>Yes, aluminum profiles can be customized to meet specific requirements. This customization can include altering the length, shape, thickness, and surface treatment of the profiles to fit the needs of various applications. Manufacturers often offer a range of standard sizes and finishes, but they can also create bespoke profiles through processes like extrusion, cutting, and bending. Customization allows for the creation of precise fits and functional designs tailored to individual projects, enhancing both aesthetics and performance.</p>

- Q: What are the different assembly options available for aluminum profiles?

- There are several assembly options available for aluminum profiles, including mechanical fastening methods such as screws, bolts, and rivets. Additionally, adhesive bonding and welding techniques can also be used to join aluminum profiles together. The choice of assembly method depends on factors such as the desired strength, aesthetics, and ease of disassembly if required.

- Q: What are the electrical insulation properties of aluminum profiles?

- Compared to plastics or ceramics commonly used in electrical applications, aluminum profiles exhibit relatively low electrical insulation properties due to their high conductivity. This attribute allows for the easy flow of electrical current. Nevertheless, with proper precautions, aluminum profiles can still be effectively utilized in electrical applications. Anodizing or coating the profiles with insulating materials like epoxy or polyurethane can significantly enhance their insulation capabilities. These coatings establish a barrier between the aluminum and the electrical current, minimizing the risk of conductivity. Moreover, aluminum profiles can be combined with other insulating materials to achieve the desired level of electrical insulation. For instance, in electrical wiring systems, aluminum conductors are frequently paired with insulating materials such as PVC or cross-linked polyethylene to ensure reliable insulation. It is crucial to recognize that while aluminum profiles may possess lower electrical insulation properties compared to other materials, they do offer other advantageous characteristics like high strength, lightweightness, and corrosion resistance. Hence, careful consideration needs to be given to the specific application and electrical requirements before selecting aluminum profiles as an electrical insulation material.

- Q: This question asks about the impact of aluminum profiles on the thermal efficiency of a building.

- <p>Aluminum profiles can significantly affect the thermal performance of a building. They are excellent conductors of heat, which means they can transfer heat quickly. This property can be both advantageous and disadvantageous. On the positive side, aluminum profiles can help dissipate heat from the building, reducing the need for air conditioning. However, they can also lead to heat loss in colder climates, reducing the building's energy efficiency. To mitigate this, thermal breaks are often incorporated into aluminum profiles to reduce heat transfer. Additionally, insulating materials can be used alongside aluminum profiles to enhance the building's thermal insulation. Proper design and material selection are crucial to optimize the thermal performance of a building with aluminum profiles.</p>

- Q: How many tons of aluminum can be produced by a ton of aluminium ingots?

- Firstly, according to the requirements of a ton of aluminum ingot made of different aluminum alloy rods, concrete can output many aluminum rods must be based on the company's standard, but personally think that a ton of aluminum rod is absolutely not up to a ton of waste in the section product, because in the process of consumption, waste can not be calculated in the product section in.

Send your message to us

Aluminum Heat Sink Extrusion Profiles for Window and Door with Advantage Price and Free Moulds

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords