Aluminum Foil Eco Friendly 8011-H18 Rolls for Pharmaceutical Wrapping of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 m²

- Supply Capability:

- 90000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Structure of Aluminium Foil Description:

Aluminium Foil is structured by aluminium paper, which is the raw material .It is suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

2. Main Features of the Aluminium Foil:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

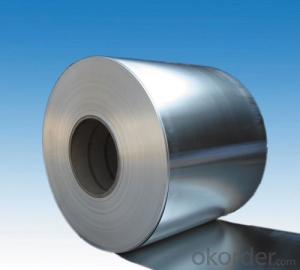

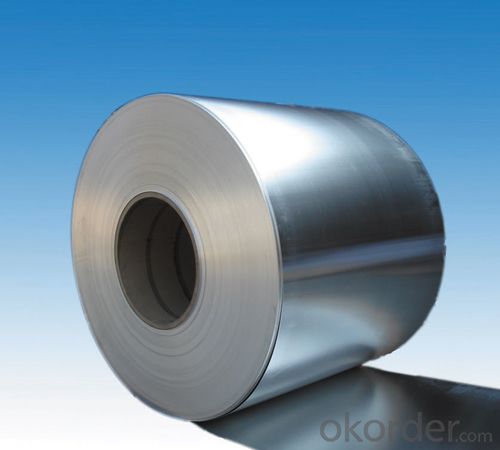

3. Aluminium Foil Images

4. Aluminium Foil Specification

OP/Ink printing/AL/HSL(printed)

OP/AL/HSL(unprinted)

Primer/AL/HSL(printable)

Aluminum Foil 8011- H18 Rolls for Pharmaceutical Wrapping can be applied to pack tablets,pills,capsules,gum and candy etc.

All raw materials come from excellent suppliers,make sure products can conform eligible animalcule and pinhole limit.

Excellent sealing strength can seal with PVC, PVC/PVDC, PET, PP, PE,alu alu foil and tropical blister foil.

Primer systems for online and offline printing, easy printing for water-base and UV inks.

Perfect printing, no fading after sealing,

According to customer needs, single side, double sides printing make better propaganda effect.

Sealing at low temperature, good for medicine and high speed processing.

High barrier against moisture, oxygen, other gases, light and UV lights.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What do you make that is quick, and tasty?Please don't say carry-out or take-awayI already figured that out! :-))

- go to her site and email them they will tell youshe is so OUT anyway, nooone watches her anymore THE MOST HATED WOMAN IN AMERICA

- Q: Maybe with chicken and bacon and almonds and goat cheese and some spinach and lettuceI KNOW that this may be fattening, I don't want to lose weight I just want to incorporate salad to my diet.

- Strawberry Spinach Salad Ingredients 2 tablespoons sesame seeds 1 tablespoon poppy seeds 1/2 cup white sugar 1/2 cup olive oil 1/4 cup distilled white vinegar 1/4 teaspoon paprika 1/4 teaspoon Worcestershire sauce 1 tablespoon minced onion 10 ounces fresh spinach - rinsed, dried and torn into bite-size pieces 1 quart strawberries - cleaned, hulled and sliced 1/4 cup almonds, blanched and slivered Directions In a medium bowl, whisk together the sesame seeds, poppy seeds, sugar, olive oil, vinegar, paprika, Worcestershire sauce and onionCover, and chill for one hourIn a large bowl, combine the spinach, strawberries and almondsPour dressing over salad, and tossRefrigerate 10 to 15 minutes before serving or Fruity Curry Chicken Salad Ingredients 4 skinless, boneless chicken breast halves - cooked and diced 1 stalk celery, diced 4 green onions, chopped 1 Golden Delicious apple - peeled, cored and diced 1/3 cup golden raisins 1/3 cup seedless green grapes, halved 1/2 cup chopped toasted pecans 1/8 teaspoon ground black pepper 1/2 teaspoon curry powder 3/4 cup light mayonnaise Directions In a large bowl combine the chicken, celery, onion, apple, raisins, grapes, pecans, pepper, curry powder and mayonnaiseMix all togetherServe! or Candied Walnut Gorgonzola Salad Ingredients 1/2 cup walnut halves 1/4 cup sugar 3 cups mixed greens 1/2 cup dried cranberries 1/2 cup crumbled Gorgonzola cheese 1 tablespoon raspberry vinaigrette 1 tablespoon white vinegar 1 tablespoon olive oil Directions Place walnuts and sugar in a skillet over medium heat, stirring constantly until the sugar dissolves into a light brown liquid and coats the walnutsRemove walnuts from skillet, and spread them out on a sheet of aluminum foil to coolPlace in a large salad bowl the mixed greens, cranberries, cheese, vinaigrette, vinegar, and olive oilToss gently; add candied walnuts, and toss again hope this helps!!!

- Q: i noticed a wierd bag under my parents bag i opened it and there was this wierd electrical box with a light switch and wires running all the way around the bed and aluminum foil underneath the mattress.then i turned on the switch and nothing noticeable happened but my moms been really sick for a while and theyre into a lot of eastern medicine/reiki bullshit so i was wondering if there was any way this thing was contributing to her illness.

- Spinach and Artichoke Dip 3 oz.Onion, medium diced 2 tspGarlic, chopped 1 ozClarified butter 1-1/2 lbsFrozen chopped spinach, thawed 1 lbArtichoke hearts, canned, chopped, coarse 1 qtCream sauce 2 tspWorcestershire sauce Salt and pepper, to taste Tabasco sauce, to taste 6 ozParmesan cheese, grated Sauté the onion and garlic in the butter until tender, without coloringAdd the spinach and sauté until hotAdd the artichoke hearts, cream sauce, Worcestershire and 4 ozof the Parmesan cheeseMix wellSeason with salt, pepper and TabascoTransfer the dip to a half hotel panTop with remaining 2 ozof Parmesan cheese and bake at 350 degrees until hot and browned on top, approx20 minutes.

- Q: Someone gave us smoked meat (pig) and I want to know the best way to re-heat itDoes anyone have any suggestions? I would really appreciate it.

- From the Reynolds Wrap web site: Occasionally when aluminum foil comes in contact with a different metal or a food that is highly salted or acidic, small pinholes are formed in the foilThis is a harmless reaction that does not affect the safety of the foodIt is difficult to predict, but may occur under the following conditions: 1When aluminum and a dissimilar metal are in contact in the presence of moisture, an electrolytic reaction may occur causing a breakdown of the aluminumTo avoid this use aluminum, glass, ceramic, plastic or paper containersDo not cover sterling silver, silverplate, stainless steel or iron utensils with aluminum foil 2A similar reaction may occur when salt, vinegar, highly acidic foods or highly spiced foods come in contact with aluminum foilThe result of these reactions is a harmless aluminum saltSome aluminum salts are used in medicines to treat stomach disordersThe food can be safely eaten; however, the aluminum salt particles can be removed from the food to improve the appearance of the food.

- Q: This year was rather warm and the bugs are expected to be 3x worse (at least)Already, we found ants in our bedroom (the big black ones)We removed all food, vacuumed, picked up everything, and sprayed Raid over the windows, the door to the hallway, and all around the bottom of the wallsI sprayed my car doors after finding a spider in thereAnyways, back to the bedroomI washed all the clothes in the room and the sheets to ensure there were none in there, eitherAre they going to come back? I'm laying here in bed worrying, I hate ants!

- chances are they will be back.sounds like carpenter ants that live in voids.aluminum tubing around windows is most common area I locate them in a homedoubtful what you sprayed will have any effect on the ants after a few daysWhether you see more depends on where they decide to forage, if they head outside from the window area you may not se them again, though the issue is not gone.

- Q: Is it safe or effective to use aluminum foil to wrap a pizza?

- <p>Yes, you can use aluminum foil to wrap a pizza, but it's important to be cautious. Aluminum foil is a good conductor of heat, which can help to cook the pizza evenly. However, it can also cause hot spots and uneven cooking if not used properly. When using aluminum foil, make sure to cover the pizza loosely, allowing for air circulation, and avoid direct contact with the pizza's surface to prevent sticking. It's also recommended to use a pizza stone or baking sheet for better heat distribution.</p>

- Q: I need to build a barge out of aluminum foil with a 30x30cm dimension and put weights in it w/o sinking,any ideas on how to build it? And if possible i need to break the previous record which is 2 kilograms.

- I might try making a rectangular or square shaped brick out of the foil, trapping air inside of itIf you can get it to seal good (roll the edges) it should be relatively flat and able to stack weights on it, kind of how a pontoon worksI use a similar method to trap food inside foil so that it holds in steam to cookI imagine that it should keep water out too.

Send your message to us

Aluminum Foil Eco Friendly 8011-H18 Rolls for Pharmaceutical Wrapping of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 m²

- Supply Capability:

- 90000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords