Aluminum Coil Car Brushed Coated Aluminum Coils for Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Brushed Coated Aluminium Coils for Metal Wall ACP Description

• Product: Aluminim coils

• Application:

corrugated roofs, outer walls, ovens, electrically controlled cabinets.

household appliances, transportation, base plate, color coating.

industrial freezers in the residential and industrial buildings.

refrigerator backplane, gas stove, air conditioner, microwave, LCD border.

• Advantage: Full production line with all kinds of coils supply

2. Main Features of the Brushed Coated Aluminium Coils for Metal Wall ACP

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

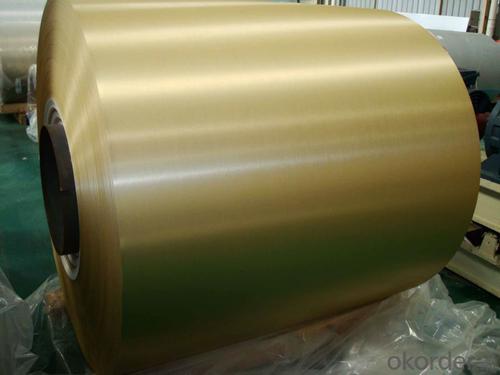

3. Brushed Coated Aluminium Coils for Metal Wall ACP Images

4. Brushed Coated Aluminium Coils for Metal Wall ACP Specification

Alloy | AA1050/1100/3003/3005/3105/5005/5052 etc |

Thickness | 0.03mm—4.0mm |

Width | 10mm—1600mm |

Coating | PVDF, PE |

Coatingthickness | Usually16-25 micron, could be 33-40 micron |

Color | According to Ral |

Standard | ASTM-B 209 GB/3008-2006 |

Usage/ApplicationsCoated Aluminum Coil/Sheet | Constructionand decoration, electronic appliances, lighting decoration, air-condition airpipe, sandwich panels and drainage, etc |

5.FAQ of Brushed Coated Aluminium Coils for Metal Wall ACP

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Are aluminum coils resistant to mold and mildew?

- Yes, aluminum coils are highly resistant to mold and mildew. Aluminum does not provide a favorable environment for mold or mildew growth, making it an excellent choice for applications where moisture and humidity are concerns.

- Q: Is it safe and effective to use aluminum coils for baking purposes?

- <p>Yes, you can use aluminum coils for baking. Aluminum is a common material used in baking pans and coils due to its excellent heat conduction properties, which allows for even baking. However, it's important to note that some people are concerned about potential health risks associated with aluminum, though these concerns are not universally accepted by the scientific community. Always ensure your aluminum baking coils are food-grade and clean to prevent any contamination.</p>

- Q: What's the color coated aluminum roll?

- Colour coated aluminium coil product information:Product category: polyester coated aluminum coil (PE), fluorocarbon coated aluminum coil (PVDF)Mylar coated aluminum coilIs a kind of anti UV ultraviolet coating, polyester resin is used in the main chain of ester containing polymer polymer as monomer, add alkyd resin, UV absorber according to gloss, can be divided into sub light and high light series. The utility model is especially suitable for indoor decoration and advertisement boards.Fluorocarbon coating aluminum coilFluorocarbon resin is a kind of fluorocarbon resin, which is composed of pigments, alcohols, esters, solvents and assistants. High temperature barbecue film,The molecular structure of the coating is close and has super weatherability. Fluorocarbon coatings can be divided into two kinds: traditional fluorocarbon and nano fluorocarbon coating according to the surface film forming structure.The utility model is especially suitable for the decoration and display of indoor, outdoor decoration, commercial chain, exhibition advertisement, etc. in public places

- Q: What are the potential applications of coil-annealed aluminum coils?

- Coil-annealed aluminum coils have a wide range of potential applications due to their unique properties. They can be used in manufacturing various products such as automotive parts, electronic components, packaging materials, construction materials, and even in the aerospace industry. The annealing process enhances the coil's flexibility, strength, and corrosion resistance, making it ideal for applications where durability, formability, and lightweight characteristics are crucial.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Cryogenic storage tanks can incorporate aluminum coils, as aluminum is a suitable material for such purposes. This is due to its low density, high thermal conductivity, and excellent resistance to corrosion. These attributes make it an excellent choice for the storage and transportation of cryogenic liquids like liquid nitrogen, oxygen, and argon. Aluminum coils can be utilized to construct the internal shell of the tank, which offers a lightweight and durable solution. Moreover, aluminum is highly malleable, enabling the creation of intricate tank shapes and designs. However, it is crucial to consider that aluminum has a higher coefficient of thermal expansion compared to materials such as stainless steel. Therefore, adequate design measures must be implemented to accommodate thermal contraction and expansion during cryogenic operations.

- Q: Can aluminum coils be used for heat exchangers?

- Indeed, heat exchangers can make use of aluminum coils. Aluminum has gained popularity as a favored option for heat exchangers owing to its exceptional thermal conductivity, light weight, and resistance to corrosion. These coils usually find application in scenarios where heat transfer is necessary, such as HVAC systems, refrigeration units, and automotive radiators. Aluminum's high thermal conductivity enables efficient heat transfer, while its corrosion resistance guarantees durability and an extended lifespan for the heat exchanger. Moreover, aluminum coils can be effortlessly molded into different shapes and sizes, thereby showcasing their versatility for various heat exchanger designs.

- Q: This question asks for the current prices of aluminum coils, which may vary based on factors such as weight, thickness, and market conditions.

- <p>The prices of aluminum coils can vary significantly depending on several factors including weight, thickness, grade, and market demand. Prices are also influenced by global economic conditions and the current state of the commodities market. As of my last update, aluminum coil prices could range from a few dollars to several hundred dollars per pound, but for the most accurate and up-to-date pricing, it's best to check with a supplier or a commodities exchange, as these prices fluctuate regularly.</p>

- Q: i dont want aluminum cookware, but how about a stainless steel set with an aluminum core. Is this the same as aluminum pots and pans? Thanks.

- The aluminum is encased in the stainless steel, usually as a thick disk in the bottom. It is an excellent conductor of heat and holds the heat well once it gets hot. All you see is the stainless, none of the aluminum because it's between two layers of stainless in the bottom of the pots. You are right, you don't want food cooked in straight aluminum, some metal taste can transfer to certain foods. That won't happen with stainless.

- Q: What are the typical thickness tolerances for aluminum coils?

- The specific manufacturing standards and industry requirements play a role in determining the typical thickness tolerances of aluminum coils. Generally, the range of thickness tolerances for aluminum coils is between +/- 0.001 and 0.005 inches. These tolerances are crucial in maintaining the thickness of the aluminum coils within acceptable limits, ensuring they meet the desired specifications and applications. It should be emphasized that the intended use of the aluminum coils, whether for architectural, automotive, or aerospace purposes, may influence the specific tolerances.

- Q: Can recycled aluminum coils be reused to create new ones, or are they only suitable for disposal?

- <p>Old aluminum coils can indeed be recycled and used to make new ones. Recycling aluminum is an efficient process that conserves resources and reduces energy consumption compared to mining and refining new aluminum. The recycling process involves melting the old coils, which can then be reshaped into new coils without losing any of their properties. This makes recycling aluminum coils a sustainable and environmentally friendly alternative to disposal.</p>

Send your message to us

Aluminum Coil Car Brushed Coated Aluminum Coils for Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords