1/0 1/0 1/0 Aluminum Wire for Window Screen Woven Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

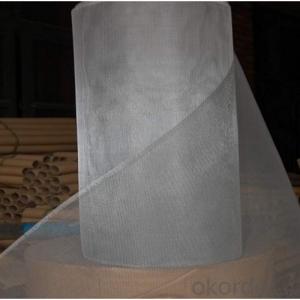

1.Structure of Aluminum Alloy Wire Description:

Aluminum Alloy Wire is acid and alkali resistant, corrosion resistance, high strength, good toughness, and it does not fade at high temperatures (120 ℃). So products with aluminum-magnesium alloy micro wire would not deform easily, and there is a good shielding effect.

Featured by small density and high strength, the aluminum magnesium alloy tool is the lightest metal component material at present. Aluminum magnesium alloy wire can be used for core wire (as a substitution of copper wire) and shielding weaving wire which are widely applied to all kinds of communication cables, coaxial cables, being the supporting products of broad band transmission network and communication network.

2.Main Features of the Aluminum Alloy Wire

The wire is no oil stain on the wire surface

The wire surface is very smooth, and there is no burrs

The wire is very beautiful

The wire surface is bright

3.Aluminum Alloy Wire Images

4.Aluminum Alloy Wire Specification

Alloy | Uyimate Tensile Strength (PSI) | Electrical Resistance | Density (g/cc) | Melting Point |

1100 | 13000 | 18 | 2.71 | 645° |

1350 | 13000 | 17 | 2.70 | 648° |

1199 | 6800 | 15 | 2.70 | 660° |

2024 | 27000 | 20.25 | 2.78 | 638° |

3003 | 16000 | 20.25 | 2.73 | 654° |

4043 | 21000 | 25 | 2.69 | 632° |

5005 | 18000 | 19.95 | 2.70 | 654° |

5052 | 28000 | 10.2 | 2.68 | 649° |

5056 | 42000 | 36 | 2.64 | 605° |

6061 | 17000 | 22 | 2.70 | 617° |

5.FAQ

1) What is quality?

We are a state-owned company and ranked No267th of Fortune 500 in 2014. There is no need of worry about quality.

2) How is your delivery time:

In General, it will take 25days

3) How about your service?

We have a professional Inspection Team.

- Q: The similarities and differences between aluminum wire and copper wire

- Color, conductivity, densityPure metallic copper; purplish red; not pure; may be golden or brown

- Q: Can solder aluminum wire with tin wire?

- Had better not, according to the chemical terms, if welded, all metal, and the water vapor in the air to form a galvanic cell, it will accelerate corrosion

- Q: What is the phenomenon of aluminium wire immersed in copper sulphate solution?

- The reaction principle is: aluminum is more active than copper, so the replacement reaction occurs.

- Q: LV how to solder, seek expert advice, please everybody

- First of all, strongly recommend the purchase of a dedicated aluminum wire feed tool, a kit will contain the following items:1. non metallic lined tubes - designed to minimize wire feed friction2. U grooved drive roller - used to prevent breakage or deformation of soft aluminum wire. These drive rollers don't scratch aluminum wires like V groove rollers. The use of V groove roller, will make the wire scraping lining pipe plug, causing wire feed failure.3. inlet and outlet guide device - designed to avoid wire scratches.4. contact contacts - use a larger diameter opening in the welding head of aluminum material, because the expansion of the aluminum wire is more expansive than that of the steel. Therefore, the size of the contact head for aluminum wire is small enough to maintain electrical contact and sufficient to allow expansion.

- Q: In the process of spark discharge machining, why hasn't the aluminum wire been fused by the high temperature produced by it?

- If it's a question, it's a question of molybdenum wire, not aluminum. You take a closer look........ That is the reason why the fuse is not tungsten molybdenum wire is synthesized, with characteristics of high temperature resistant tungsten, molybdenum also has the flexibility of the process, a cooling liquid cooling, so high temperature fuse will not be generated

- Q: What are the processes for LED production?

- Pressure welding: the electrode is connected to the LED core by aluminum wire or wire bonder, which is used as the lead for the current injection. LED installed directly on the PCB, the general use of aluminum wire welding machine. (making white TOP-LED requires wire welding machine)

- Q: Why is it that the steel structure of the bridge is black after spraying aluminum? What hazards do you have after blackening?

- Spraying aluminum is a physical process in which the aluminum wire with high purity (99.6%) is filled with the surface of the steel by arc atomization

- Q: How to properly install fuse

- Do not screw the tight fuse too tight or too loose, so that the contact is good and the fuse is not damaged.

- Q: LED from chip to epitaxial, substrate, and then to the final packaging process

- Epitaxial sheet refers to the MOCVD processed film.The basic principle is: in the epitaxial growth of a substrate is heated to a suitable temperature (including SiC, Si, and sapphire), InGaAlP is in the control of gaseous substances transported to the surface of the substrate, the growth of specific single crystal films.

- Q: My family always switch zero line insurance burning is going on?

- Are you sure the burning line is zero? I can responsibly tell you: zero line is not insured! Because we use voltage is 220V, once the breakage of zero line (fuse) then the voltage by line voltage (voltage between the live wire and zero line) to phase voltage (voltage between two FireWire), which is the 220V voltage multiplied by the square root of 3 times = 380V

Send your message to us

1/0 1/0 1/0 Aluminum Wire for Window Screen Woven Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords