4 Gauge Aluminum Wire - High Purity AA1050 Aluminium Wires at Low Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Solid MIG and TIG wires for welding pure aluminium

2.excellent ductlity,corrosion resistance

3.well electrical conductivit

Detailed Introduction

Product name:Aluminum

Type: pure aluminum

Melting point: 660°C(1220°F)

Boiling point:2467°C(4473°F)

Density under 20°C(60°F): 2.70g/cm3

Application:

Just like silicon, aluminum is a common deoxidizer. Aluminum is also used as grain refiner and occationally as heating material. Aluminum wire permits to achieve high and constant Aluminum recovery. Please note that late aluminum wire feeding during refining can cause solid alumina inclusions to appear which will affect steel castability. Calcium cored wire addition can remedy this situation by transforming solid alumina into liquid calcium-aluminates.

Specification

Dia 9mm cored wire is a kind of medium size wire, which is suitable for the ladle of capacity less than 20 MT and most of cast iron spheroidization

Φ9mm Cored wire Specification

* The above specifications can be adjusted upon request.

Dia 13mm cored wire is a typical size wire for steel industry, which is suitable for all kinds of steel ladles and alloys.

Dia 16mm cored wire is suitable for the alloy adding to the steel ladle of capacity more than 250MT.

Φ13mm - Φ16mm cored wire specification

* The above specifications can be adjusted upon request.

Diameter and fill rate

Diameter and fill rate

Products | Diameter and fill rate(g/m) | Application | ||

Φ9mm | Φ13mm | Φ16mm | ||

CaSi | 110 | 220 | 330 | Steel desulphurization, deoxidization, inclusion modification and castability |

CaFe | 122 | 250 | 365 | Low silicon Steel modification, inclusion modification and steel desulphurization, deoxidization, clogging prevention, castability |

AlCaFe | 150 | 300 | For low silicon steel application, besides the function of CaFe cored wire but steel deoxidization and grain refinement | |

FeTi | 165 | 370 | 570 | Microalloying and deoxidization |

FeBo | 200 | 550 | 825 | Microalloying |

C | 140 | 205 | Trimming addition, steel carbon adding | |

Mg | 60 | 140 | 210 | Desulphurization and nodularisation |

FeSiMg | 235 | 335 | Nodularisation | |

CaSiBa | 225 | 330 | Inclusion modification | |

Al | 200 | 300 | Deoxidization and grain refinement | |

S | 190 | 280 | Re-sulphurising of free cuting steels | |

FeSi | 235 | 335 | Nodularisation | |

The above fill rates can be adjusted upon request. The thickness of steel strip is 0.35~0.50mm, which conforms to the stipulation of GB716,GB3526,GB1323. The weight allowance for each 200g is no more than 2.5%. The joints for each 1000 meters are no more than 3. The cored wires are widely used for calcium treatment and microalloying in the ladle metallurgy, which have the advantages of element precise control and easy use. | ||||

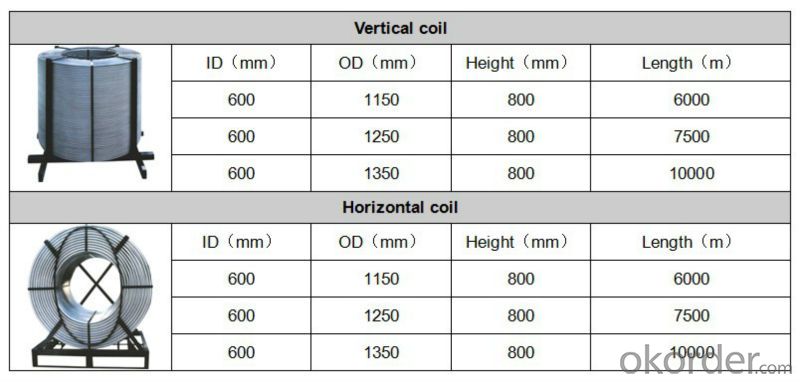

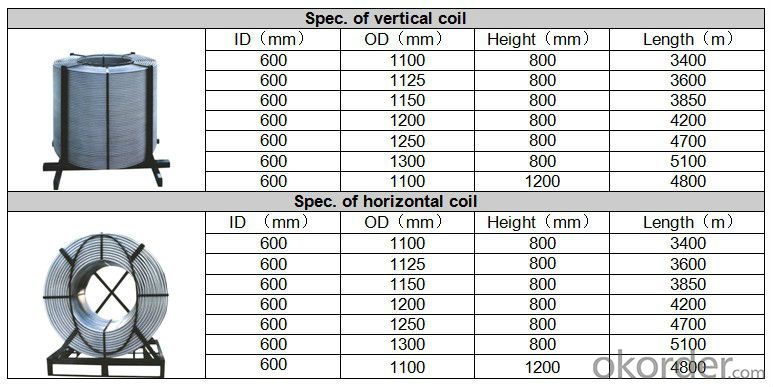

Packing

Based on the design of feeding machine, cored wire coils can be made vertically or horizontally, With the special connector, the coils can be fed continuously, The packing also can be customized upon request.

- Q: The bottom of the cooker is leaking. How can it be repaired?

- This approach can usually take some time.Other fixes are unreliable.

- Q: How to remove the black dirt in the iron pan?

- Honey method. Apply a little honey to the dirt at the bottom of the pot, and clean it in half an hour with pan cloth.

- Q: What is the iron chromium aluminum wire

- Usage: used in industrial electric stove, household appliance, far infrared equipment, etc..

- Q: Why not use copper, iron, aluminum wire instead of fuse?

- When the line is overloaded or the short-circuit current increases, the fuse is dissolved to cut off the current, protect the circuit and the electrical effect. If copper, iron, aluminum wire is used instead,

- Q: Can the cement in the iron pot be removed?

- Although aluminum is easy to use, but it is easy to form black stains, can use the fruit to be cleared. Such as tomato, with boiled cook tomato, then cooked tomato water to wash the pot boil, as long as the repeated several times, bright natural recovery of aluminum.

- Q: How to tell how thick the wire is?

- The so-called 1 square wire mm, refers to the single stranded (BV) core sectional area is 1mm - line, which is based on the relationship between PI and the diameter of the calculation to.

- Q: How to use and maintain straightening and breaking machine

- The wire cutting machine is mainly aimed at (0.6-1.5MM) wire straightening and cutting. The broken wire machine can cut off 4 wires with one time, while the straight wire machine can only cut off one; the broken wire machine mainly cuts off the binding wire of the building. To send a few drawings: 1 is broken wire machine, 2 is a straight wire machine

- Q: Copper wire, steel wire, aluminum wire, heat transfer performance, sorting

- Copper wire and aluminium wire are used in wire and cable industry, and steel wire is the most widely used in wire rope industry

- Q: Why is it that the steel structure of the bridge is black after spraying aluminum? What hazards do you have after blackening?

- After the spraying of aluminium is finished, sealing paint shall be used immediately to protect against oxidation.

- Q: What is the material of the toilet with aluminium drawing effect?

- There are two kinds of surface drawing, one is PVC film, and the base material is metal aluminum honeycomb panel, this price is slightly higher

Send your message to us

4 Gauge Aluminum Wire - High Purity AA1050 Aluminium Wires at Low Prices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches